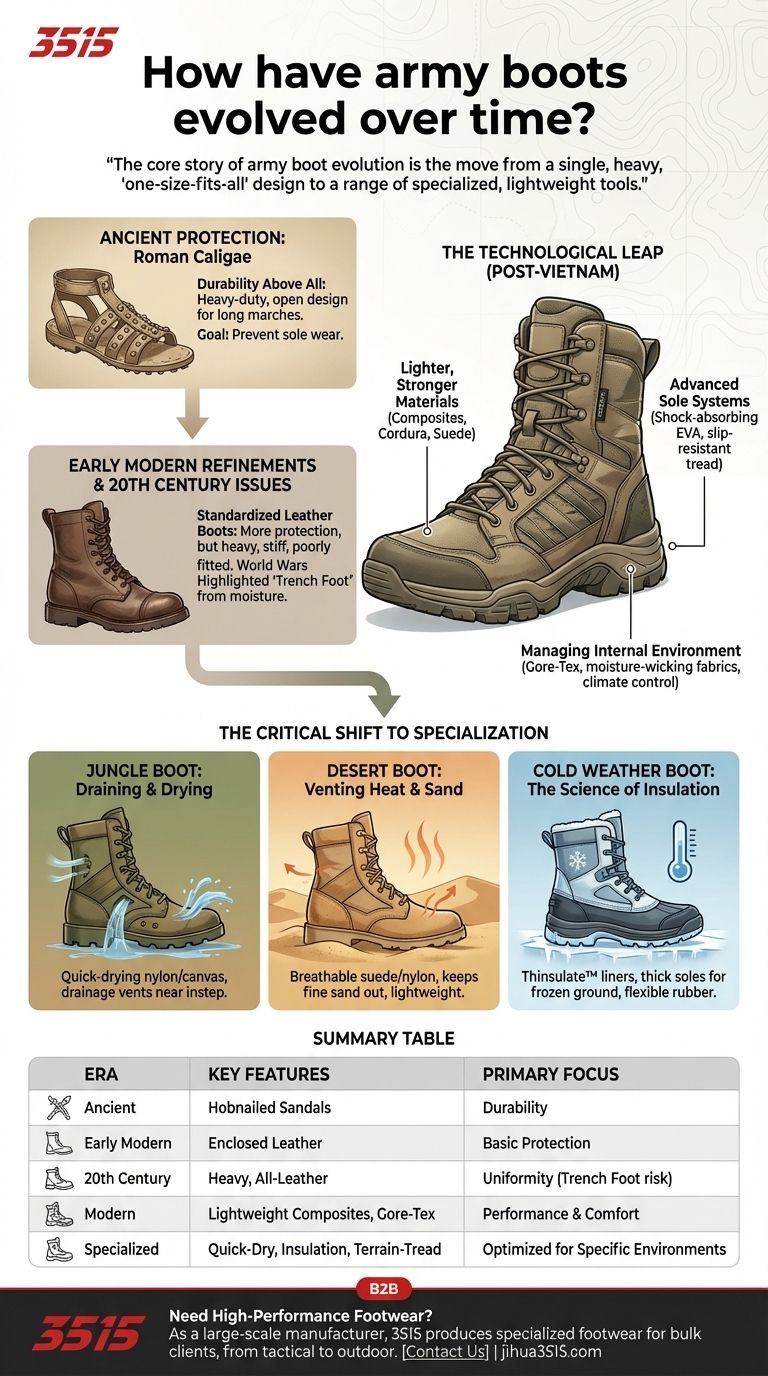

The evolution of army boots reflects a fundamental shift from simple foot protection to sophisticated performance gear. They have transformed from ancient hobnailed sandals designed for durability into modern, technologically advanced systems engineered for specific environments, from sweltering deserts to frozen tundras. This progression mirrors the changing demands of warfare, where speed, endurance, and soldier survivability are paramount.

The core story of army boot evolution is the move from a single, heavy, "one-size-fits-all" design to a range of specialized, lightweight tools. This change was driven by the realization that a soldier's mobility and ability to fight effectively are directly tied to the performance and comfort of their footwear.

From Ancient Protection to Modern Performance

The primary function of military footwear has always been to protect the feet of soldiers. However, the definition of "protection" and the methods used to achieve it have changed dramatically over centuries.

The Roman Blueprint: Durability Above All

The earliest ancestors of the army boot were the Roman Caligae, which were essentially heavy-duty, hobnailed sandals. Their open design was suited for warm climates, and the iron hobnails provided excellent durability for long marches on Roman roads. The focus was singular: prevent the sole from wearing out.

Early Modern Refinements: The Rise of the Boot

By the 1600s, European armies, notably the British, began to standardize enclosed leather boots. This design offered more protection from the elements and terrain than a sandal. However, these early boots were still heavy, stiff, and often poorly fitted, prioritizing mass-produced uniformity over individual soldier comfort.

The 20th Century: The Problem of "One Size Fits All"

The World Wars highlighted the critical flaws in traditional all-leather boot design. Heavy, slow-drying boots contributed to devastating conditions like trench foot, a non-combat injury that incapacitated huge numbers of soldiers. This experience proved that simply keeping water out wasn't enough; footwear had to manage moisture from both inside and out.

The Technological Leap: What Defines a Modern Boot?

Post-Vietnam, military footwear design underwent a technological revolution. The focus shifted from passive protection to actively enhancing a soldier's performance by reducing weight, improving comfort, and increasing traction.

A Focus on Lighter, Stronger Materials

Modern boots have moved beyond all-leather construction. They now incorporate lightweight composite materials, nylon fabrics like Cordura, and suede. This dramatically reduces the weight a soldier must lift with every step, which directly translates to less fatigue over a long mission.

Advanced Sole Systems for Grip and Support

The sole is no longer just a simple layer of leather or rubber. Modern designs feature a multi-part system with shock-absorbing midsoles (often made of EVA foam) to reduce impact and slip-resistant outsoles with aggressive, terrain-specific tread patterns for superior grip.

Managing the Internal Environment

Perhaps the most significant change is the focus on climate control. Technologies like Gore-Tex offer a waterproof yet breathable membrane to keep feet dry from external moisture while allowing sweat vapor to escape. Linings made of moisture-wicking fabrics pull sweat away from the skin, preventing blisters and other moisture-related injuries.

The Critical Shift to Specialization

The single biggest evolution in modern military footwear is the end of the "one-boot-for-all-missions" philosophy. Boots are now highly specialized tools designed for the specific environment in which they will be used.

The Jungle Boot: Draining and Drying

In hot, humid environments, keeping water out is impossible. Instead, jungle boots are designed to let water drain out quickly through vents near the instep. They are made from quick-drying nylon and canvas to prevent them from becoming waterlogged and heavy.

The Desert Boot: Venting Heat and Sand

Desert boots are built for breathability. They often use a combination of suede and nylon to allow heat and moisture to escape, keeping the foot cooler. Their design prioritizes keeping fine sand out while remaining lightweight and supportive on rocky or sandy terrain.

Cold Weather Boots: The Science of Insulation

For cold and arctic environments, the key is insulation. These boots feature thick, integrated liners made from materials like Thinsulate to trap body heat. They also have thick soles to provide a barrier against the frozen ground and specialized rubber compounds that remain flexible and grippy in freezing temperatures.

Making the Right Choice for Your Goal

This history of specialization is not just for military use; it directly informs the wide range of tactical and work boots available today. Understanding the design philosophy behind each type allows you to select the right tool for your specific need.

- If your primary focus is all-weather versatility: Look for a boot with a waterproof-breathable membrane and a moderately aggressive, all-terrain outsole.

- If your primary focus is hot, dry environments: Prioritize lightweight boots made from breathable materials like suede and nylon over heavy waterproofing.

- If your primary focus is wet or humid conditions: Consider non-waterproof boots with drainage vents and quick-drying synthetic materials for superior performance.

Ultimately, understanding the evolution of the army boot is to understand that footwear is not just an accessory, but a critical piece of performance equipment.

Summary Table:

| Era | Key Features | Primary Focus |

|---|---|---|

| Ancient (e.g., Roman Caligae) | Hobnailed sandals, open design, leather | Durability for long marches |

| Early Modern (1600s-1800s) | Enclosed leather boots, standardized | Basic protection from elements |

| 20th Century (World Wars) | All-leather, heavy, slow-drying | Uniformity, but led to trench foot |

| Modern (Post-Vietnam) | Lightweight composites, Gore-Tex, specialized soles | Soldier performance, comfort, and survivability |

| Specialized (Jungle/Desert/Cold) | Quick-dry fabrics, insulation, terrain-specific treads | Optimized for specific environments (heat, moisture, cold) |

Need High-Performance Footwear for Your Market?

As a large-scale manufacturer, 3515 produces a comprehensive range of specialized footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of tactical, work, and outdoor boots—from lightweight desert designs to insulated cold-weather models—ensuring you get the right product for your target audience.

Let us help you equip your customers with the right gear. Contact our team today to discuss your manufacturing needs!

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

People Also Ask

- Does the army still use jump boots? From Battlefield to Ceremonial Symbol

- What is the significance of 1600 denier nylon in army combat boots? Unmatched Durability Meets Soldier Comfort

- How did combat boots transition from military use to popular culture? From Battlefield to Fashion Statement

- What new footwear solution has the Army developed for jungle environments? Meet the Jungle Combat Boot

- What role did combat boots play in the Vietnam War? Beyond Practicality to Personal Identity

- What are the advantages and disadvantages of crepe soles in desert boots? Discover the Pros and Cons

- What is the timeline for finalizing the jungle boot design? A Detailed Look at the 2018-2019 Schedule

- What are the key features of army boots? Durability, Support & All-Terrain Traction Explained