Ultimately, you must test the work environment because "non-slip" is not a universal standard. The effectiveness of a shoe's slip resistance is entirely dependent on the specific hazards it encounters, such as the type of flooring and the liquids or contaminants present. Without this context, you are simply guessing about safety.

Choosing the right non-slip shoe isn't about finding the single "best" option on the market. It's about creating a precise match between a shoe's design features and the specific slip-and-fall risks unique to your work environment.

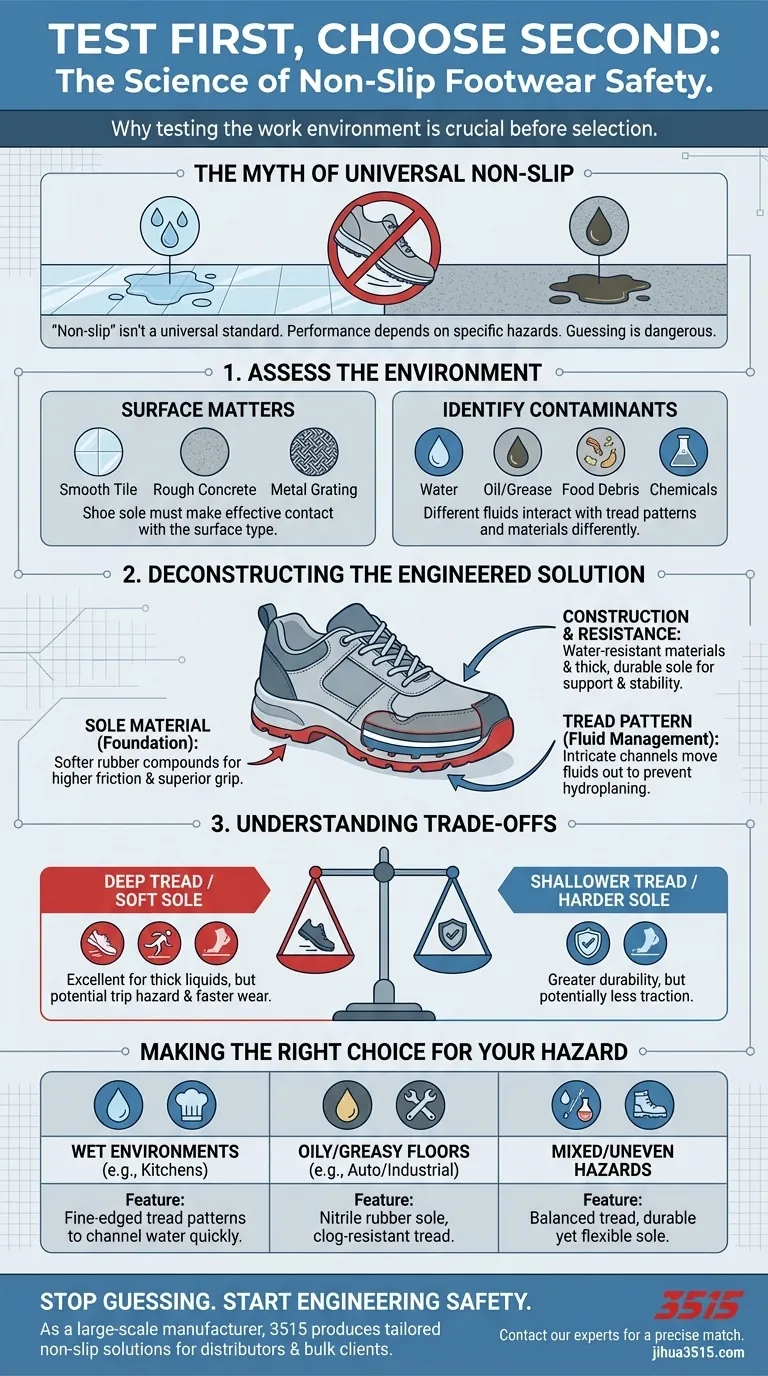

The Myth of a Universal Non-Slip Shoe

Many assume that any shoe labeled "slip-resistant" will provide adequate protection in any hazardous setting. This is a dangerous misconception. A shoe that performs exceptionally on a water-covered tile floor may fail completely on an oily concrete surface.

It Starts with the Surface

The first factor to assess is the floor itself. A smooth, polished tile floor presents a very different challenge than a rough, unsealed concrete floor or a grated metal catwalk. The shoe's sole must be able to make effective contact with the specific surface type.

Identify the Contaminants

Next, you must identify the primary contaminants. Water, oil, grease, food debris, and chemical spills all interact with flooring and shoe soles differently. A tread pattern designed to channel water away might become clogged and ineffective with thicker, more viscous fluids like grease.

Deconstructing an Effective Non-Slip Shoe

Once you understand the environmental challenges, you can analyze how a shoe's specific features are designed to overcome them. The right shoe is an engineered solution to a specific problem.

Sole Material is the Foundation

The material of the outsole is your primary point of contact with the ground. Most non-slip shoes use a softer rubber or synthetic rubber compound. These materials offer a higher coefficient of friction, providing a superior grip compared to harder materials.

Tread Pattern Manages Fluids

The pattern of grooves on the bottom of the shoe is not for decoration. These intricate channels are designed to move fluids out from under the sole. This prevents a layer of liquid from forming between the shoe and the floor, which is a primary cause of hydroplaning and slips.

Construction and Water Resistance

A shoe's overall build quality contributes to safety and stability. A thick, durable sole provides better support, reducing foot and back fatigue during long shifts. Water-resistant materials are also crucial for keeping feet dry, which prevents discomfort and maintains stability inside the shoe.

Understanding the Trade-offs

Selecting a shoe for one specific hazard can sometimes create a compromise in another area. It's critical to be aware of these potential downsides.

Tread Depth vs. Trip Hazard

An extremely aggressive and deep tread pattern is excellent for displacing thick liquids. However, on dry or uneven surfaces, these deep lugs can sometimes act as a trip hazard or wear down unevenly and quickly.

Sole Softness vs. Durability

Softer rubber compounds provide an excellent grip but may wear out faster, especially on abrasive surfaces like rough concrete. A harder compound might last longer but offers less traction.

Contaminant-Specific Design

A sole designed specifically for oily conditions might not perform as well in an environment with only water. The key is to identify the most common and dangerous hazard in your workplace and optimize for it.

Making the Right Choice for Your Environment

Your environmental assessment should directly guide your final selection. Prioritize the features that counter the biggest risks you face daily.

- If your primary focus is wet environments (e.g., kitchens, food processing): Prioritize shoes with numerous, fine-edged tread patterns designed to quickly channel away water.

- If your primary focus is oily or greasy floors (e.g., automotive shops, industrial manufacturing): Choose a shoe with a sole made from a material like nitrile rubber that resists degradation from oils and has a tread pattern that won't easily clog.

- If your primary focus is mixed hazards or uneven surfaces: Look for a balanced shoe with a moderately aggressive tread and a durable yet flexible sole that provides both grip and stability.

Ultimately, a proactive analysis of your workspace transforms buying safety shoes from a guess into an informed engineering decision.

Summary Table:

| Environmental Factor | What to Look For | Ideal Shoe Feature |

|---|---|---|

| Floor Surface | Smooth tile, rough concrete, metal grating | Sole material and flexibility for surface contact |

| Primary Contaminant | Water, oil, grease, chemicals | Tread pattern designed to channel or resist specific fluids |

| Common Hazards | Wet floors, oily surfaces, uneven terrain | Sole softness for grip vs. durability for longevity |

Stop guessing about workplace safety. As a large-scale manufacturer, 3515 produces a comprehensive range of non-slip footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots engineered for specific environments—from kitchens to industrial floors.

Let us help you match the perfect shoe to your unique hazards. Contact our experts today for a tailored solution that reduces slip risks and enhances worker safety.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What types of workplace hazards require protective footwear? Essential Guide for Workplace Safety

- What are the EN ISO 20345 norms for safety shoes? A Guide to Choosing the Right Protection

- What materials are used in the construction of these boots? A Guide to Velour Leather, Textile & PU Soles

- What do the markings on ASTM-compliant safety shoes indicate? Decode the Safety Labels for Maximum Protection

- How is puncture resistance evaluated in footwear soles? Balance Protection, Comfort & Safety