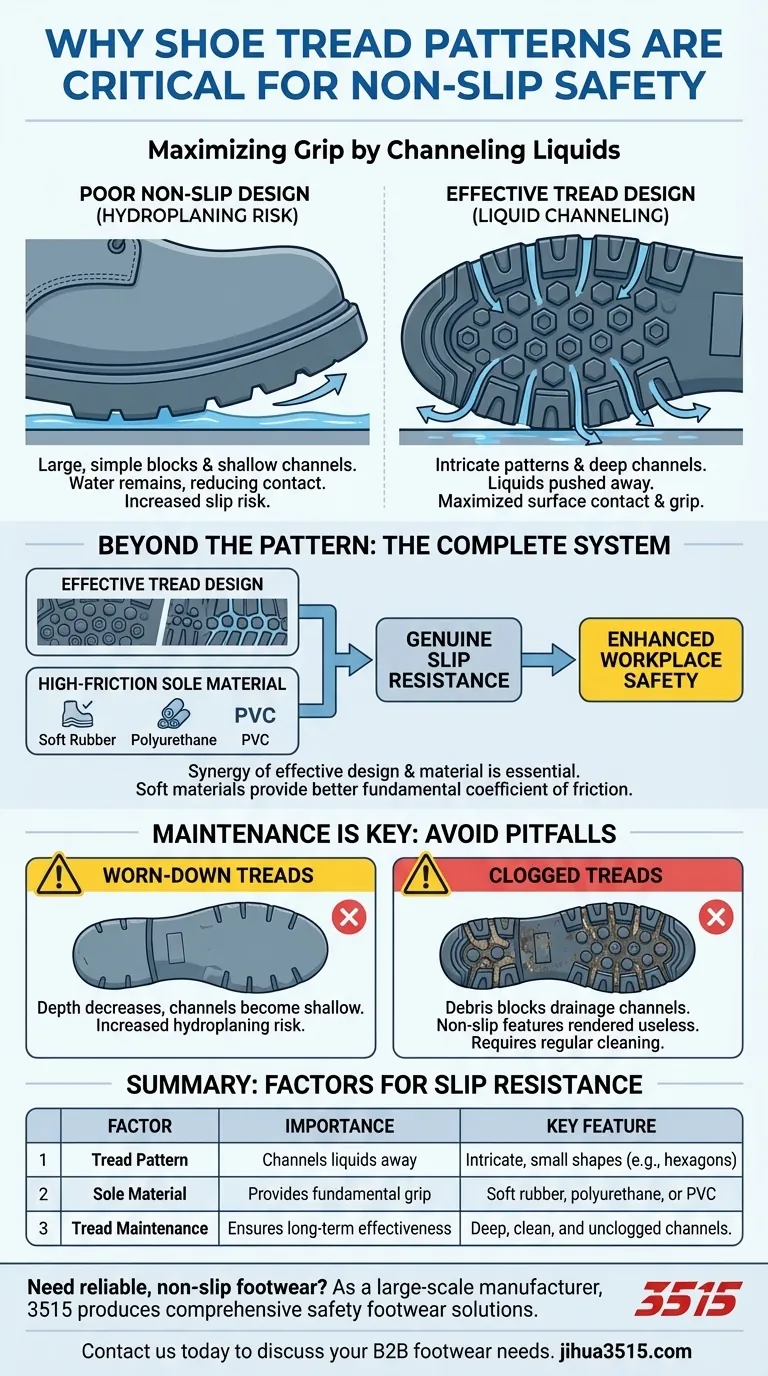

The tread pattern of a shoe is critical for its non-slip properties because its design exists for one primary reason: to channel liquids away from the sole. On a wet or greasy surface, intricate patterns with small shapes like hexagons or circles create pathways that push fluids out from underneath your foot, maximizing the contact between the sole and the ground to maintain grip.

While an intricate tread pattern is the most visible sign of a non-slip shoe, true slip resistance is the result of a complete system. It is the combination of an effective tread design, a high-friction sole material, and proper maintenance that ensures safety.

How Tread Design Prevents Slips

To understand why tread is so important, it helps to think of a car tire on a wet road. A smooth surface would simply slide over the water—a phenomenon known as hydroplaning. A shoe's tread is engineered to prevent this exact scenario on a smaller scale.

The Principle of Channeling Liquids

The grooves, channels, and shapes that make up a tread pattern are not random. Their purpose is to act as a drainage system.

When you step on a wet or oily floor, these channels immediately push the liquid out and away from the center of the sole. This clears a path for the solid parts of the tread to make direct contact with the ground.

Why Shape and Size Matter

Not all tread patterns are created equal. The effectiveness is determined by the design's complexity.

Small, intricate shapes are more effective than large, simple blocks. These tighter patterns create more edges to bite into the surface and more channels for liquid to escape, significantly increasing the shoe's ability to maintain traction.

Beyond the Pattern: The Complete Non-Slip System

An effective tread pattern is necessary, but it is not sufficient on its own. It works in concert with the material of the outsole to provide genuine slip resistance.

The Critical Role of Sole Material

The material of the outsole determines the shoe's fundamental coefficient of friction. Look for materials specifically chosen for their gripping properties.

Materials like soft rubber, polyurethane, or PVC provide naturally better traction on a variety of surfaces compared to harder, less forgiving plastics or leather.

Maximizing Surface Area Contact

The goal of the tread and material is to maximize the amount of sole touching a dry surface, even when the floor is wet.

The small, tight shapes of a good non-slip tread increase the overall surface area of the sole that can make contact with the ground once liquids have been channeled away.

Common Pitfalls and Maintenance

A shoe's non-slip capabilities are not permanent. They degrade over time and require attention to remain effective.

The Danger of Worn-Down Treads

Just like a car tire, a shoe's tread wears down with use. As the tread depth decreases, the channels become too shallow to effectively push liquids away.

A worn-out tread provides no pathway for fluid flow, dramatically increasing the risk of hydroplaning and slipping.

The Impact of Clogged Treads

The drainage channels only work if they are clear. Debris like dirt, grime, or food particles can become lodged in the tread.

When these channels are clogged, the shoe cannot displace liquid, rendering the non-slip features useless. Regular cleaning is essential to maintain performance.

How to Evaluate a Non-Slip Shoe

When selecting or assessing footwear for safety, you need to look at the entire system, not just one feature.

- If your primary focus is maximum safety in wet or oily environments: Prioritize shoes that combine a soft rubber sole with an intricate, small-patterned tread that has deep, clearly defined channels.

- If you are assessing your current footwear: Inspect the tread depth for significant wear and ensure the channels are consistently kept clean and free of debris.

Ultimately, understanding these elements empowers you to look beyond simple marketing claims and choose footwear that genuinely enhances your safety.

Summary Table:

| Factor | Importance for Slip Resistance | Key Feature |

|---|---|---|

| Tread Pattern | Channels liquids away from sole | Intricate, small shapes (e.g., hexagons) |

| Sole Material | Provides fundamental grip | Soft rubber, polyurethane, or PVC |

| Tread Maintenance | Ensures long-term effectiveness | Deep, clean, and unclogged channels |

Need reliable, non-slip footwear for your team or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of non-slip shoes and boots, engineered with effective tread patterns and high-friction materials to ensure maximum safety.

Contact us today to discuss your footwear needs and enhance workplace safety with our proven solutions.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

People Also Ask

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today