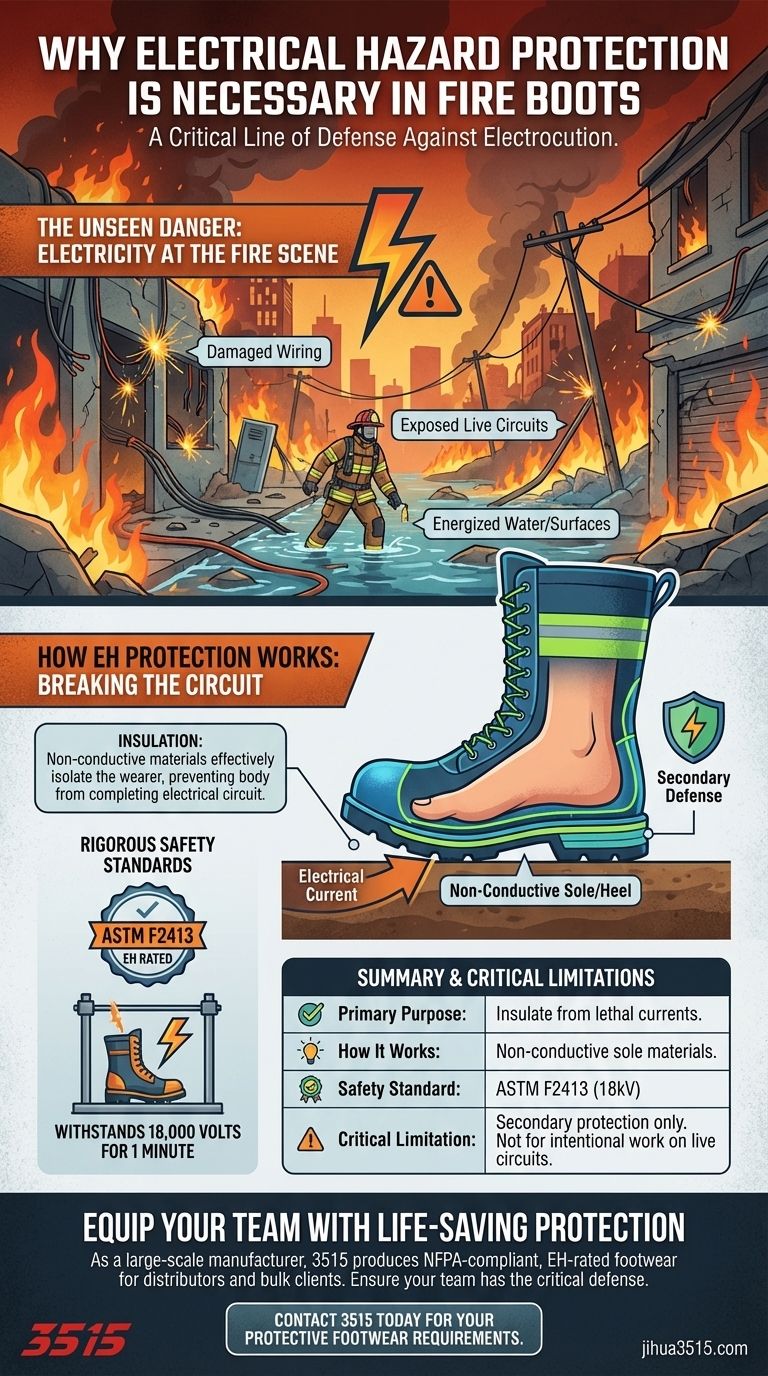

In short, electrical hazard protection is necessary in fire boots to serve as a critical line of defense against electrocution. At emergency scenes, firefighters often work around damaged structures with exposed live wires and energized equipment, and these boots are designed to insulate their bodies from potentially lethal electrical currents.

A fire scene is an electrically unpredictable environment. Electrical hazard (EH) protection transforms a boot from simple footwear into a piece of life-saving equipment by using non-conductive materials to stop the flow of electricity through the body.

The Unseen Danger: Electricity at the Fire Scene

Firefighting goes beyond battling flames; it involves navigating structurally compromised and chaotic environments where the normal rules of electrical safety no longer apply.

Why Fire Environments Are Electrically Hazardous

Fires and the water used to extinguish them create a perfect storm for electrical danger. High heat melts wire insulation, and structural collapse can sever conduits, exposing live circuits within walls, floors, and ceilings.

Downed power lines outside a structure or water coming into contact with damaged electrical systems can energize surfaces and pools of water, creating a widespread and often invisible threat.

The Body as a Conductor

The human body can easily become part of an electrical circuit. If a firefighter makes contact with an energized source, the current will seek the fastest path to the ground, which is often through their body.

Without proper insulation, this can lead to severe burns, cardiac arrest, or death. EH-rated boots are designed to break this circuit at the feet.

How Electrical Hazard (EH) Protection Works

EH protection is not an active feature but an inherent property of the boot's construction, materials, and design, all governed by strict safety standards.

The Principle of Insulation

The core function of an EH-rated boot is insulation. The entire sole and heel assembly are constructed from materials that do not conduct electricity, such as specialized rubber or polymer compounds.

This non-conductive barrier effectively isolates the wearer from the ground, preventing their body from completing an electrical circuit and allowing current to pass through them.

Rigorous Safety Standards

To be effective, this protection must meet a specific, measurable benchmark. The prevailing standard is set by ASTM International (formerly the American Society for Testing and Materials).

An EH-rated boot must be able to withstand the application of 18,000 volts at 60 Hz for one minute with no current flow or leakage to the foot. This test certifies the boot's integrity under extreme electrical exposure.

Understanding the Limitations

While essential, it is crucial to understand that EH protection is a secondary defense mechanism and has limitations that every firefighter must respect.

A Secondary Source of Protection

EH-rated footwear is intended as a secondary source of protection in case of accidental contact with live circuits. It is not designed for primary protection, meaning firefighters should never intentionally work on or near energized equipment relying solely on their boots.

Standard lockout/tagout procedures and other primary safety measures for de-energizing circuits must always be the first priority.

The Impact of Wear and Environment

The insulating properties of a boot can be compromised. Deep cuts, punctures from nails, or the embedding of conductive materials like metal shavings can negate the protection.

Furthermore, excessive moisture, particularly salt water, can reduce the sole's insulating effectiveness. Regular inspection of your boots for damage is critical to ensuring their safety features remain intact.

Making the Right Choice for Your Role

Selecting the right footwear means matching the boot's certified protections to the specific hazards you are most likely to face.

- If your primary focus is structural or urban firefighting: An NFPA-compliant boot with a certified EH rating is a non-negotiable piece of your personal protective equipment.

- If you are a crew chief or safety officer: Ensure your team understands that EH boots are a last-resort safeguard, not a tool for working with live electricity, and implement regular boot inspections.

- If you are responsible for equipment procurement: Always verify that boots meet or exceed the ASTM F2413 standard for Electrical Hazard protection to provide the highest level of safety.

Ultimately, viewing EH protection not as an optional feature but as an integral, life-saving system is fundamental to firefighter safety.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Purpose | Insulate the wearer from lethal electrical currents at fire scenes. |

| How It Works | Uses non-conductive materials in the sole/heal to block electrical flow. |

| Safety Standard | Must withstand 18,000 volts for 1 minute (ASTM F2413). |

| Critical Limitation | Secondary protection only; not for intentional work on live circuits. |

Equip Your Team with Life-Saving Protection

As a large-scale manufacturer, 3515 produces a comprehensive range of NFPA-compliant, EH-rated footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure your team has the critical defense they need against unpredictable electrical hazards.

Contact 3515 today to discuss your protective footwear requirements and enhance your safety procurement.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What work boot features are essential for warehouse and light industrial settings? Prioritize Lightweight Protection & All-Day Comfort

- How can you test if a boot fits properly? A 4-Step Guide to Perfect Fit & Comfort

- What materials are used in composite toe work boots, and what are their advantages? Get Lightweight, Non-Conductive Safety

- What is Gristle Rubber primarily used for? Unbeatable Durability for Industrial Footwear

- What are the construction differences in moc toe boots? Choose the Right Build for Durability & Value

- Why should management prioritize certified high-quality safety boots? Enhance Safety Barriers & Operational Reliability

- What are the steps for caring for engineer boots to ensure longevity? A Guide to Decades of Wear

- What additional safety features do structural firefighting boots provide? Beyond Heat Resistance