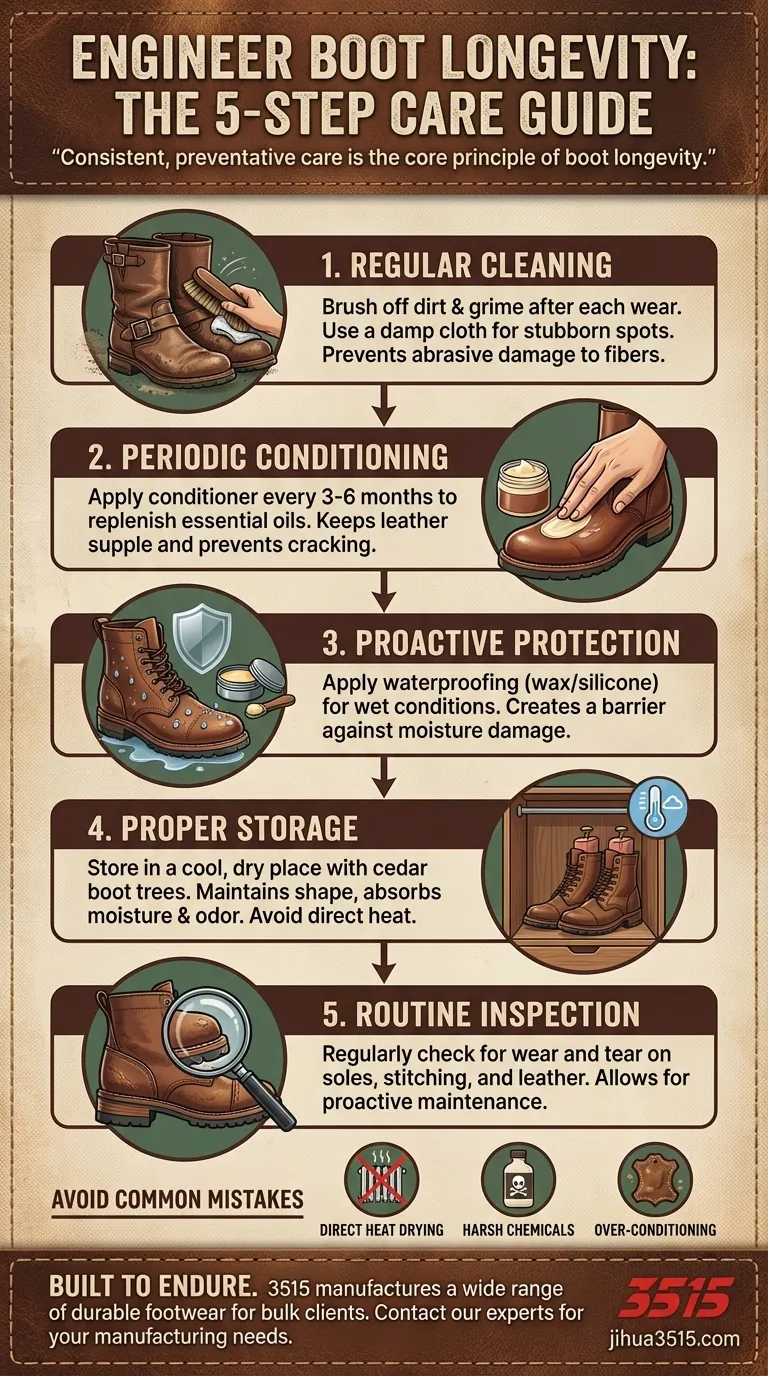

The definitive process for caring for engineer boots involves five key steps: regular cleaning, periodic conditioning, proactive protection from moisture, proper storage, and routine inspection. This regimen prevents leather from drying and cracking, preserves its structural integrity, and ensures your boots remain a durable, long-term investment.

The core principle of boot longevity is not intensive, infrequent repair but consistent, preventative care. A simple routine of cleaning and conditioning is the most effective way to protect your investment and ensure decades of reliable wear.

The Foundation: A Consistent Cleaning Routine

Proper care begins with the most basic step: keeping your boots clean. This isn't just about appearance; it's about preventing premature wear.

Why Regular Cleaning Matters

Dirt, dust, and grime are abrasive. As you walk, these fine particles work their way into the leather, slowly grinding down the fibers and weakening the material over time.

A quick clean after each wear removes these damaging particles before they can cause harm, preserving the leather's strength and finish.

The Right Tools for the Job

You don't need a complex kit. The essentials are a soft horsehair brush to remove loose debris and a clean, damp cloth for more stubborn dirt.

For heavy soiling, a specialized leather cleaner or a mild soap (like saddle soap) can be used, but always sparingly.

The Cleaning Process

First, use a dry brush to whisk away all loose dirt and dust from the leather and the welt (the seam where the upper meets the sole).

If needed, wipe the boots down with a slightly damp cloth. For tougher spots, use a small amount of specialized cleaner, then wipe away any residue.

The Core of Longevity: Conditioning the Leather

Leather is a natural skin; without moisture, it will dry out, become brittle, and crack. Conditioning replenishes the essential oils that keep it strong and supple.

Why Leather Needs Conditioning

Everyday exposure to sun, heat, and moisture leaches the natural fats and oils from the leather. This is the primary cause of cracking and permanent damage.

Conditioner restores this moisture, maintaining the leather's flexibility and preventing the fibers from breaking down.

How Often to Condition

The frequency depends entirely on use and climate. For boots worn a few times a week in a moderate climate, conditioning every 3-6 months is sufficient.

If your boots are frequently exposed to harsh sun, water, or mud, you may need to condition them as often as once a month.

Applying Conditioner Correctly

Always start with clean, dry boots. Apply a small, dime-sized amount of conditioner to a clean cloth or your fingers and work it into the leather in a thin, even layer.

Pay special attention to seams and flex points. Let the conditioner absorb for several hours or overnight, then buff off any excess with a clean, dry cloth.

Understanding the Trade-offs: Common Care Mistakes

Knowing what not to do is as important as knowing what to do. Avoiding these common pitfalls will prevent you from accidentally damaging your boots.

The Problem of Over-Conditioning

While essential, too much conditioner can be harmful. It can oversaturate the leather, making it feel mushy, clogging its pores, and potentially weakening its structure. Stick to thin, even coats and only apply when the leather feels dry.

Using Harsh Chemicals or Soaps

Never use household detergents, cleaning solvents, or alcohol-based products on your boots. These chemicals strip the leather of its natural oils far too aggressively, leading to rapid drying and cracking.

Improper Drying Methods

The single fastest way to ruin leather boots is to dry them with direct heat. Placing them near a radiator, vent, or open flame will literally cook the leather, making it brittle and causing it to crack beyond repair. Always let your boots air-dry naturally.

Smart Storage and Proactive Protection

How you store your boots and prepare them for the elements plays a significant role in their overall lifespan.

The Ideal Storage Environment

Always store your boots in a cool, dry place away from direct sunlight. A closet is ideal. Avoid damp basements or hot attics, which can promote mildew or dry out the leather.

Using cedar boot trees is highly recommended. They help the boots maintain their shape, absorb excess moisture and odor, and smooth out creases that can turn into cracks.

Proactive Waterproofing

If you frequently wear your boots in wet conditions, applying a waterproofing product can provide an essential barrier against moisture. These products, often wax or silicone-based, help repel water without sealing the leather's pores entirely.

The Power of Rotation

If possible, avoid wearing the same pair of boots every single day. Giving them a day off in between wears allows them to fully air out and dry, which significantly extends their life.

A Simple Care Regimen for Your Boots

Your specific routine should match how you use your boots. Use these guidelines to create a care schedule that works for you.

- If your primary focus is daily wear in a stable climate: Concentrate on brushing your boots after each wear and storing them with boot trees.

- If your primary focus is durability in harsh weather: Prioritize regular conditioning and applying a quality waterproofing product to protect against moisture damage.

- If your primary focus is long-term preservation for occasional use: Ensure you condition the leather at least twice a year to prevent it from drying out in storage.

Ultimately, consistent and mindful care is the key to transforming a good pair of boots into a lifelong companion.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Clean | Brush after wear; use damp cloth or mild soap | Removes abrasive dirt and grime |

| 2. Condition | Apply conditioner every 3-6 months | Replenishes oils to prevent cracking |

| 3. Protect | Use waterproofing for wet conditions | Creates a barrier against moisture damage |

| 4. Store | Use cedar boot trees in a cool, dry place | Maintains shape and absorbs moisture |

| 5. Inspect | Regular check for wear and tear | Allows for proactive maintenance |

Ready to build a boot collection that lasts a lifetime? As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of rugged shoes and boots, engineered for longevity. Let us help you provide your customers with footwear built to endure. Contact our expert team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- How does the fitting compare between pull-on and lace-up work boots? Convenience vs. Control

- What role do anti-slip safety boots play in mitigating fall risks? Ensure Stability for High-Altitude Construction

- What are the key features of Western work boots? A Hybrid of Style, Safety & Comfort

- What happened to Wellington boots after World War I? From Military Gear to Industrial Staple

- How do moc toe boots differ from round-toe boots? A Guide to Rugged vs. Versatile Style

- What materials are waterproof boots typically made of? A Guide to Rubber, Leather & Membranes

- How do ergonomic designs enhance comfort in work boots? Boost All-Day Productivity & Reduce Fatigue

- Why is it important to select breathable and supportive materials for work boot uppers? Enhance Safety and Comfort