At their core, engineer boots are a specific style of American work boot known for their heavy-duty, pull-on design. They are most famously worn by motorcyclists, but their origins lie in demanding industrial environments where durability and safety were paramount.

The engineer boot is defined by its simple, laceless construction and signature ankle strap—a design born from pure function that evolved into a cultural icon of rebellion and the open road.

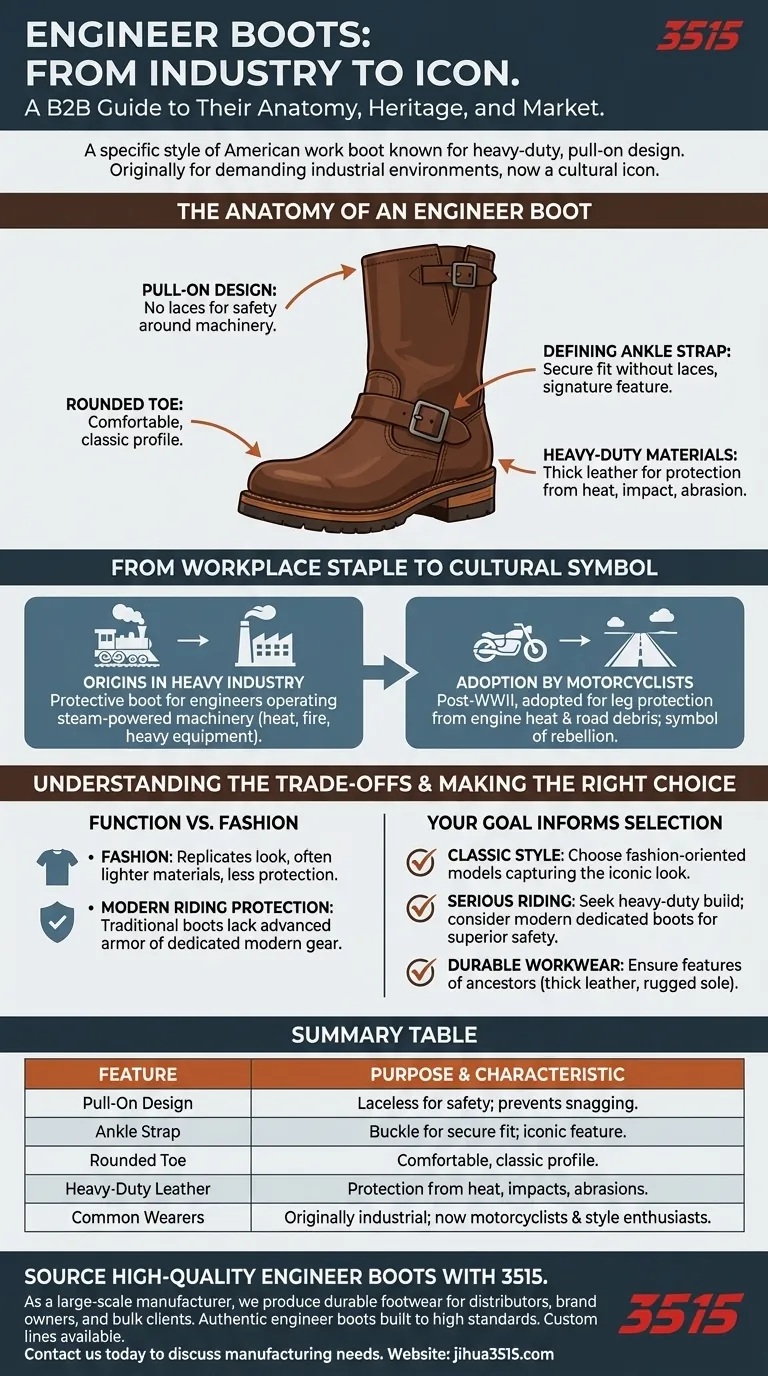

The Anatomy of an Engineer Boot

To understand the boot, you must first understand its distinct components. Each feature serves a purpose rooted in its workwear heritage.

The Pull-On Design

Engineer boots are notable for their lack of laces. This was a critical safety feature for their original wearers, such as steam locomotive engineers, as it prevented the boot from getting caught in heavy machinery.

The Defining Ankle Strap

A leather strap with a metal buckle across the instep or ankle is the boot's most recognizable feature. Its primary function is to allow the wearer to tighten the boot for a secure fit, since there are no laces to do so.

The Rounded Toe

Most traditional engineer boots feature a simple, rounded toe. This provides a comfortable, unrestrictive fit and a classic profile that emphasizes the boot's rugged construction.

Heavy-Duty Materials

True engineer boots are built from thick, durable leather. This construction was designed to protect the wearer's feet from heat, impacts, and abrasions in harsh working conditions.

From Workplace Staple to Cultural Symbol

The journey of the engineer boot from the factory floor to the motorcycle is key to understanding its modern identity.

Origins in Heavy Industry

The style was developed as a protective work boot for men in occupations that involved fire, heat, and heavy equipment. The name itself is a direct reference to the engineers who operated steam-powered machinery.

Adoption by Motorcyclists

After World War II, motorcyclists adopted the engineer boot for many of the same reasons. The tall shaft protected their legs from the heat of the engine and debris from the road, while the sturdy build offered a degree of protection in a crash.

Understanding the Trade-offs

While iconic, the engineer boot is not always the optimal choice for every situation in the modern world. It's crucial to distinguish between its heritage and its current applications.

Function vs. Fashion

Many engineer boots on the market today are designed primarily for fashion. They may replicate the classic look but often use lighter materials and construction methods that do not offer the same level of protection as their vintage counterparts.

Protection for Modern Riding

While historically popular, traditional engineer boots lack the advanced protective features of modern, purpose-built motorcycle boots. They do not have the reinforced ankle armor, torsional stiffness, or impact-absorbing materials found in dedicated riding gear.

Making the Right Choice for Your Goal

Your reason for wanting engineer boots should directly inform your selection.

- If your primary focus is classic style: You can choose from a wide range of fashion-oriented boots that capture the iconic look without the heavy build.

- If your primary focus is serious motorcycle riding: Seek out models that emphasize heavy-duty construction and consider if a dedicated, modern riding boot might offer superior safety.

- If your primary focus is durable workwear: Ensure the boot you choose has the features of its ancestors, such as thick leather and a rugged, oil-resistant sole.

Understanding the engineer boot's heritage is the key to appreciating its enduring place in both work and style.

Summary Table:

| Feature | Purpose & Characteristic |

|---|---|

| Pull-On Design | Laceless for safety; prevents snagging on machinery. |

| Ankle Strap | Buckle for a secure fit; the boot's most iconic feature. |

| Rounded Toe | Provides a comfortable, classic profile. |

| Heavy-Duty Leather | Offers protection from heat, impacts, and abrasions. |

| Common Wearers | Originally industrial workers; now motorcyclists and style enthusiasts. |

Ready to Source High-Quality Engineer Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of boots, including authentic engineer boots built to the highest standards of quality and durability.

Whether you're looking to stock a classic style or develop a custom line, we can help you deliver the right product to your market.

Contact us today to discuss your manufacturing needs and get a quote!

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What physical protections are provided by the S1 standard and integrated steel toecaps in industrial safety boots? Ensure Ultimate Foot Safety & Hazard Protection

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort

- Why is the use of steel-toe safety footwear critical during the maintenance of sugar factory press chains? Protect Your Team