To put it simply, Goodyear welted shoes cost more because of the complex, labor-intensive construction process and the higher quality materials required. This method, which involves stitching a leather strip (the welt) to the upper and the insole, demands significant skill and time compared to mass-produced, glued-on (cemented) soles.

The high initial price of a Goodyear welted shoe is not for the shoe itself, but for a durable and repairable platform. You are investing in a longer lifespan and a lower long-term cost-per-wear, fundamentally changing the economics of your footwear.

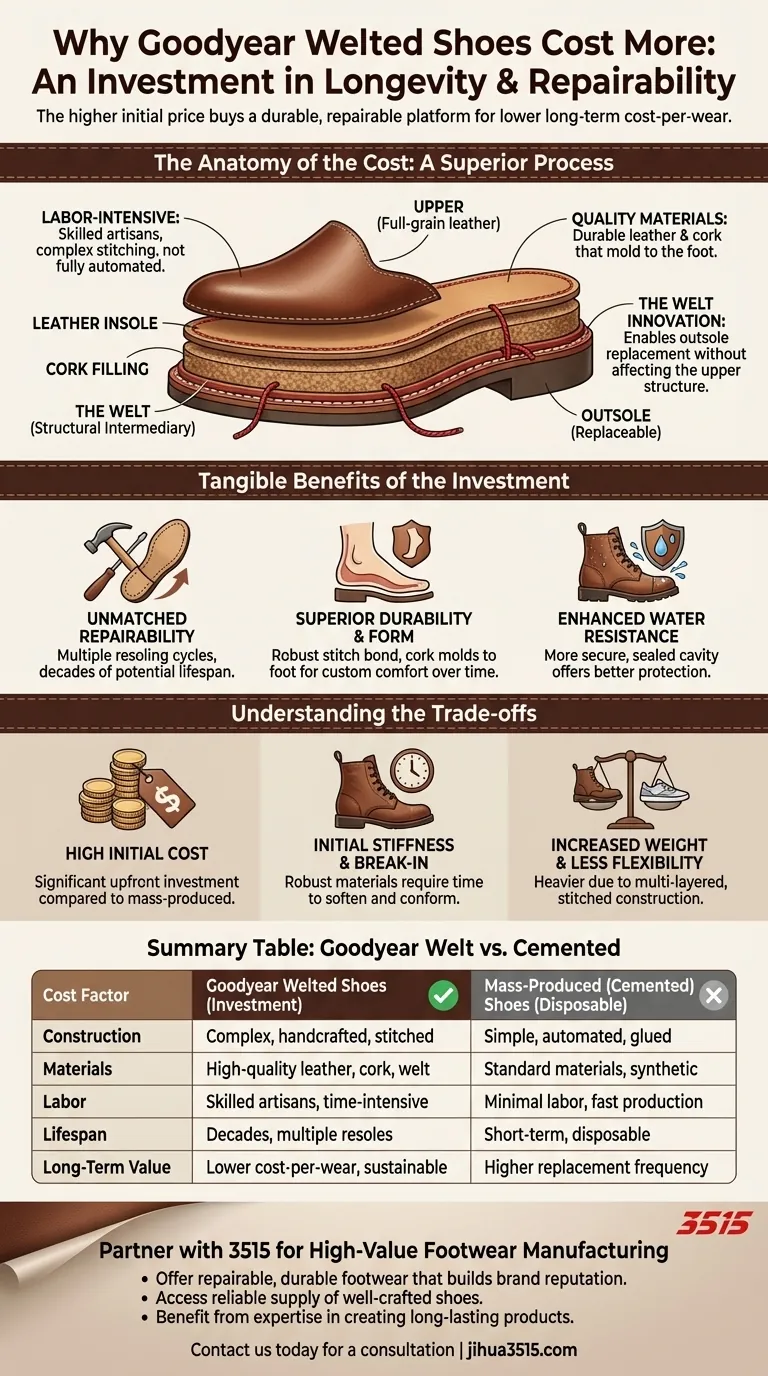

The Anatomy of the Cost

The price difference isn't arbitrary; it's a direct reflection of a superior manufacturing process designed for longevity. Understanding the individual components of this cost reveals the shoe's inherent value.

A Labor-Intensive Process

The Goodyear welting method is significantly more complex than modern alternatives. It requires skilled artisans to manage specialized machinery that stitches the components together precisely.

This level of craftsmanship cannot be fully automated, making labor a primary cost driver. In contrast, cemented construction simply involves gluing the sole to the upper, a fast and inexpensive process.

The Role of Quality Materials

A shoe built to be repaired must be made from materials that can endure. The Goodyear welt process necessitates the use of durable full-grain leather uppers, sturdy leather insoles, and often a cork filling.

These materials are chosen not just for their appearance but for their ability to hold stitches, mold to the foot over time, and withstand multiple resoling cycles.

The Welt: A Buffer for Longevity

The key innovation is the welt itself—a strip of leather that runs along the perimeter of the outsole. It acts as a structural intermediary, stitched to both the upper and the insole.

The outsole is then stitched directly to the welt. This means the sole can be removed and replaced by a cobbler without ever disturbing the fundamental structure of the shoe's upper.

The Tangible Benefits of the Investment

The higher upfront cost translates directly into measurable, long-term advantages that disposable footwear cannot offer.

Unmatched Repairability

This is the core benefit. Because the outsole is stitched to the welt and not directly to the upper, a cobbler can easily remove the old sole and attach a new one.

This resoling process can be repeated multiple times, allowing a single pair of shoes to last for decades as long as the leather upper is properly cared for.

Superior Durability and Form

The stitched construction creates an incredibly robust bond between all parts of the shoe. This structure provides exceptional longevity and helps the shoe maintain its shape over years of wear.

Over time, the leather insole and cork filling mold to the shape of your foot, creating a custom-like fit that becomes more comfortable with age.

Enhanced Water Resistance

The Goodyear welt construction creates a more secure and sealed cavity between the insole and the outsole. This minimizes the path for water to penetrate the shoe from below, offering better protection in damp conditions compared to cemented soles.

Understanding the Trade-offs

No construction method is perfect for every situation. Objectivity requires acknowledging the potential downsides.

The High Initial Cost

The most obvious trade-off is the significant upfront investment. These shoes are substantially more expensive than mass-produced alternatives, which can be a barrier for many.

Initial Stiffness and Break-in

The robust materials and complex layers make Goodyear welted shoes feel stiff out of the box. They typically require a break-in period for the leather and cork to soften and conform to your foot.

Increased Weight and Less Flexibility

Compared to a lightweight, cemented sneaker, a Goodyear welted shoe is heavier and less flexible due to its multi-layered, stitched construction.

Making the Right Choice for Your Goal

Ultimately, the "better" shoe depends entirely on your priorities.

- If your primary focus is long-term value and sustainability: The high initial cost of a Goodyear welt is easily justified by its decades-long potential lifespan and superior repairability.

- If your primary focus is immediate affordability and out-of-the-box comfort: A simpler, cemented construction offers a lower price point and requires no break-in period.

- If your primary focus is performance in harsh weather: The enhanced water resistance and durable build of a Goodyear welt make it a more reliable choice.

Choosing a Goodyear welted shoe is an investment in a product designed to be maintained, not replaced.

Summary Table:

| Cost Factor | Goodyear Welted Shoes | Mass-Produced (Cemented) Shoes |

|---|---|---|

| Construction | Complex, handcrafted, stitched | Simple, automated, glued |

| Materials | High-quality leather, cork, welt | Standard materials, synthetic |

| Labor | Skilled artisans, time-intensive | Minimal labor, fast production |

| Lifespan | Decades, multiple resoles | Short-term, disposable |

| Long-Term Value | Lower cost-per-wear, sustainable | Higher replacement frequency |

Ready to Invest in Footwear Built to Last?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including premium Goodyear welted constructions designed for longevity and superior performance.

We help you:

- Offer your customers high-value, repairable footwear that stands the test of time.

- Access a reliable supply of well-crafted shoes that enhance your brand's reputation.

- Benefit from our expertise in creating durable products that reduce long-term costs.

Let's discuss how our manufacturing expertise can bring lasting value to your business.

Contact us today for a consultation

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

People Also Ask

- What materials are best for athletic activities in warm climates? Stay Cool with Moisture-Wicking Fabrics

- Does more ground contact area mean better support? Unlock the Secrets of Stable Footwear

- What is a Flyknit shoe? The Ultimate Guide to Seamless, Lightweight Performance

- What are the characteristics of canvas as a shoe material? A Guide to Lightweight, Breathable Footwear

- What are the benefits of athletic-style work shoes? Boost Comfort and Safety for Your Team