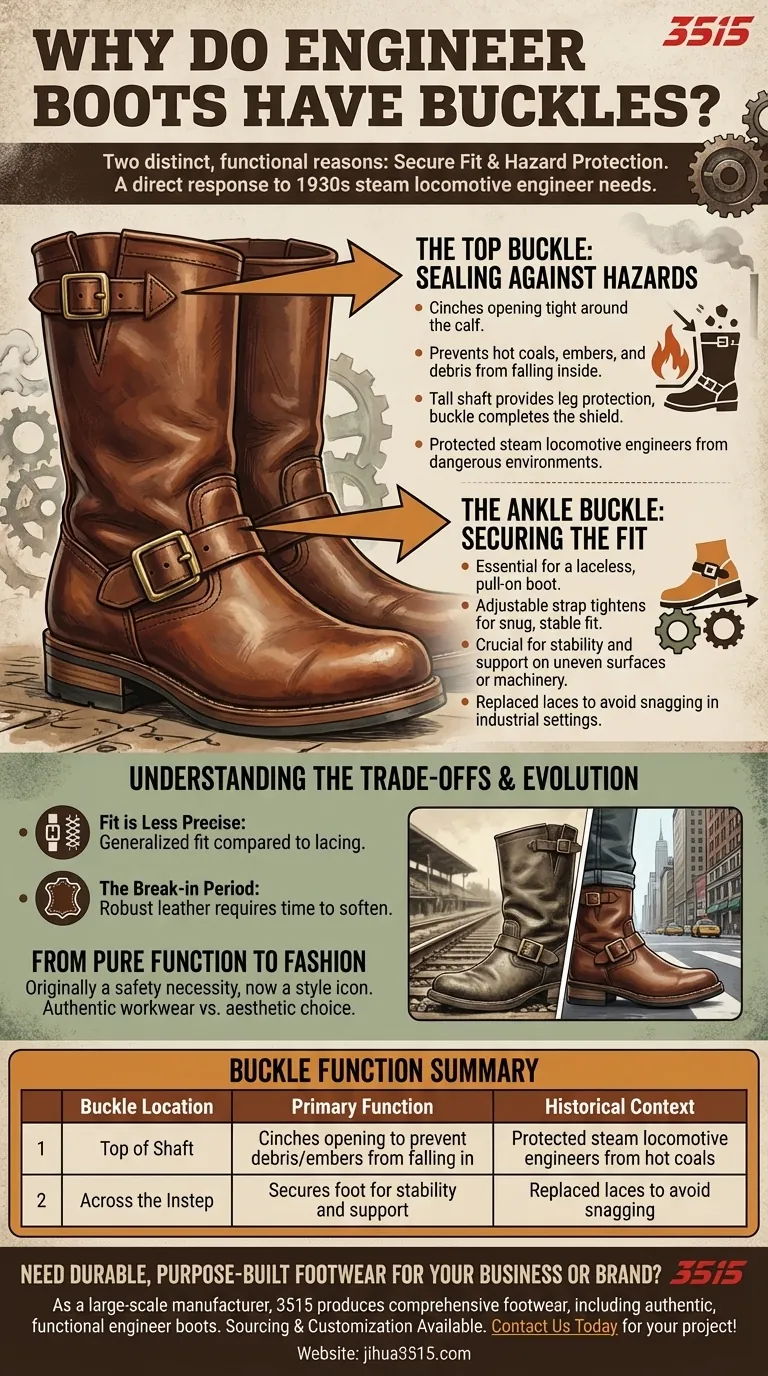

Engineer boots have buckles for two distinct, functional reasons: to secure the fit around the ankle and to tighten the top opening of the boot, which historically prevented hot embers and debris from falling inside. This dual-buckle system was a direct solution to the hazards faced by the workers they were designed for.

The design of the engineer boot is a direct response to the hazardous conditions faced by steam locomotive engineers in the 1930s. Every feature, especially the buckles, was engineered for maximum protection and a secure, laceless fit in environments filled with heat, coal, and heavy machinery.

The Original Design Philosophy: Protection First

To understand the buckles, you must first understand the environment the boots were built for. They were not an aesthetic choice but a matter of safety and practicality.

Born from the Age of Steam

Engineer boots were developed for the men operating and maintaining steam locomotives. These "engineers" worked in dangerous conditions, surrounded by intense heat, falling hot coals, and powerful, moving machinery.

The footwear needed to be tough, protective, and free of potential snag hazards, which led to its unique, laceless design.

The Top Buckle: Sealing Against Hazards

The buckle at the top of the boot's shaft, often on a small strap called a gusset, had one critical job: to cinch the opening tight around the calf.

This created a seal to prevent hot coals, embers, or other worksite debris from falling into the boot and causing serious injury. The tall shaft provided leg protection, and this buckle completed the shield.

The Ankle Buckle: Securing the Fit

As a pull-on boot without laces, the engineer boot needed a way to secure the wearer's foot and prevent it from slipping.

The adjustable buckled strap across the instep (the top of the foot near the ankle) allowed workers to tighten the boot for a snug fit. This was crucial for stability and support when walking on uneven surfaces or operating machinery.

Understanding the Trade-offs

The laceless, buckled design was a brilliant solution for its time, but like any specialized design, it comes with inherent trade-offs.

Fit is Less Precise

A buckle system, while secure, does not offer the same micro-adjustability as a full lacing system. The fit is more generalized, which is why finding the right size and last is critical for comfort.

The Break-in Period

The robust leather and simple construction that make engineer boots so durable also contribute to a notoriously stiff initial feel. A significant break-in period is often required for the leather to soften and mold to the wearer's foot.

From Pure Function to Fashion

Today, the engineer boot's rugged aesthetic has made it a style icon. While high-quality reproductions maintain the original functional design, many fashion-oriented versions may have buckles that are more decorative than practical.

Making the Right Choice for Your Goal

Understanding the original purpose of the buckles helps inform what you should look for in a pair of boots today.

- If your primary focus is authentic workwear and durability: The buckles are a critical functional component. Ensure they are made of solid metal and that the leather straps are thick enough to hold tension for a secure fit.

- If your primary focus is style and aesthetics: The buckles are the boot's most iconic design element, symbolizing a legacy of industrial resilience and classic Americana.

Ultimately, the buckles on an engineer boot are a constant reminder of its purpose-built heritage.

Summary Table:

| Buckle Location | Primary Function | Historical Context |

|---|---|---|

| Top of Shaft | Cinches opening to prevent debris/embers from falling in | Protected steam locomotive engineers from hot coals |

| Across the Instep | Secures foot for stability and support | Replaced laces to avoid snagging in industrial settings |

Need durable, purpose-built footwear for your business or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including authentic, functional engineer boots designed for durability and safety.

Let us help you source or customize high-quality footwear that meets your exact needs. Contact us today to discuss your project!

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- Why are industrial safety boots with steel toes necessary for machine operators? Essential Foot Protection for Safety

- What are penetration-resistant insoles in safety footwear? Steel vs. Textile for Ultimate Protection

- What are the requirements for a protective toe cap? Meet ASTM F2413 Standards for Maximum Safety

- Why do operations involving heavy fruit bunches and 'gancu' require anti-smash and anti-puncture safety boots?

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?