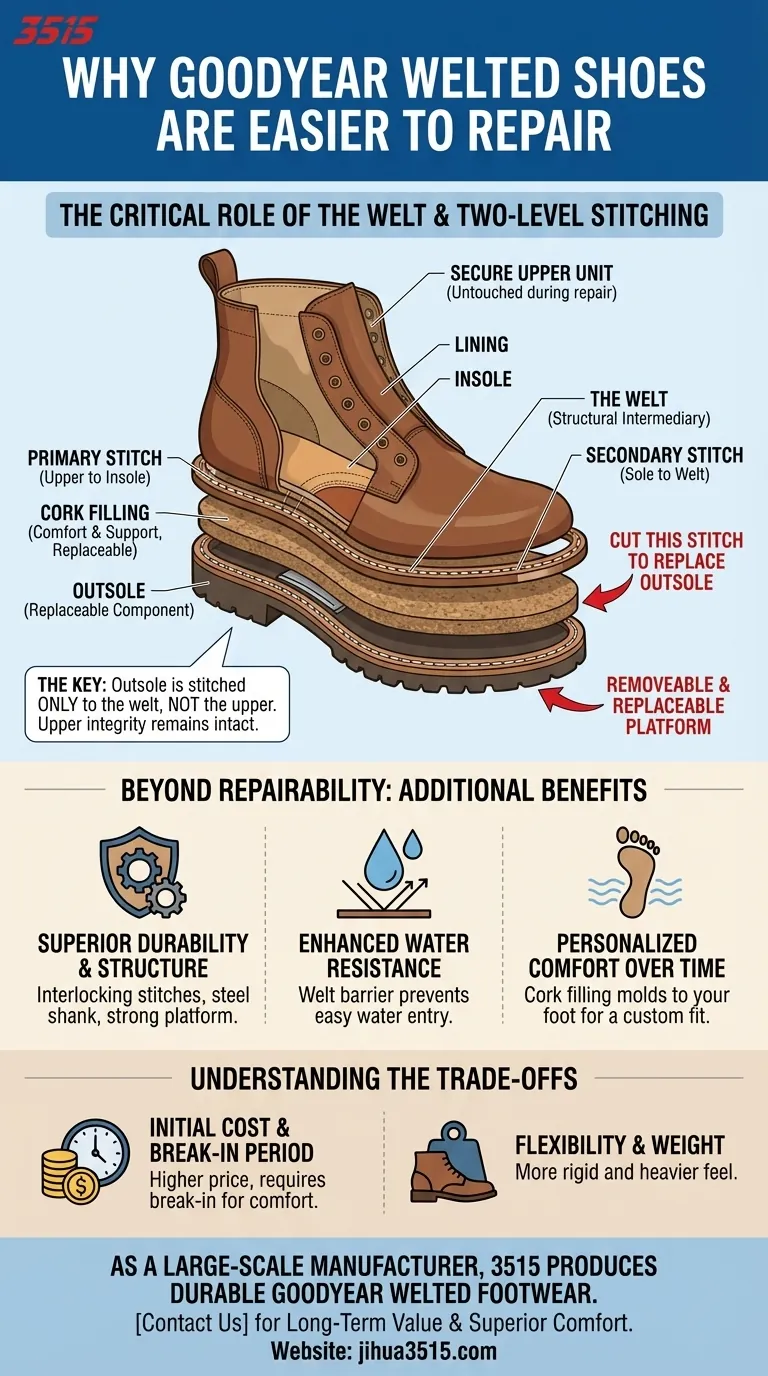

At its core, Goodyear welted shoes are easier to repair because of a single, crucial component: the welt. This strip of leather acts as a structural intermediary between the shoe's upper and its outsole, allowing a cobbler to replace a worn-out sole without ever disturbing the main body of the shoe.

The key to a Goodyear welt's repairability is its two-level stitching system. The outsole is stitched only to the welt, not the upper, creating a durable and easily replaceable platform that significantly extends the life of the footwear.

Deconstructing the Goodyear Welt

To understand why this construction method is so revered for its longevity, we must first look at how the shoe is assembled. It's a method invented in 1869 by Charles Goodyear Jr., son of the man who pioneered vulcanized rubber.

The Critical Role of the Welt

The welt is a strip of leather that is stitched around the bottom edge of the shoe's upper. This is the first and most important seam, as it permanently attaches the upper to the insole.

The outsole, the part of the shoe that contacts the ground, is then stitched directly to this welt. This second seam is what you see running along the top edge of the sole.

How the Components Work Together

This two-part construction creates a distinct separation. The upper and insole form one secure unit, while the outsole is attached to the welt as a separate, replaceable component.

This design also creates a cavity between the insole and the outsole. This space is typically filled with a layer of granulated cork, which plays a vital role in both comfort and support.

The Resoling Process Explained

When the outsole wears down, a cobbler simply cuts the second stitch that attaches the sole to the welt. The old sole and worn cork can then be removed cleanly.

A new cork layer is added and a brand new outsole is stitched onto the existing welt. Because the primary stitch holding the upper to the insole is never touched, the structural integrity of the shoe remains completely intact.

Beyond Repairability: The True Benefits

While easy resoling is the most famous feature, the Goodyear welt construction method delivers several other distinct advantages that contribute to its reputation for quality.

Superior Durability and Structure

The interlocking stitches and multiple layers create an exceptionally strong and durable shoe. A steel shank is often embedded within the construction, providing arch support and maintaining the shoe's shape over years of use.

Enhanced Water Resistance

The welt acts as a barrier, preventing water from easily seeping in between the upper and the sole. While not fully waterproof, this construction offers significantly more protection from the elements than a simple glued or cemented sole.

Personalized Comfort Over Time

The cork filling between the insole and outsole is a key feature for comfort. As you wear the shoes, your body heat and the pressure of your stride cause the cork to compress and mold perfectly to the unique shape of your foot, creating a custom-like fit.

Understanding the Trade-offs

No construction method is perfect, and the Goodyear welt comes with its own set of considerations. Objectivity requires acknowledging them.

Initial Cost and Break-in Period

Goodyear welted shoes are more labor-intensive to produce, which results in a higher initial purchase price compared to cemented footwear.

The robust construction and multiple layers can also make the shoes feel stiff at first. They often require a "break-in" period as the leather softens and the cork insole begins to mold to your foot.

Flexibility and Weight

By design, a welted shoe is more rigid and often heavier than a shoe where the sole is simply glued on. For those who prioritize a lightweight, sneaker-like feel, this construction may feel too substantial.

Is a Goodyear Welted Shoe Right for You?

Choosing the right footwear is about aligning its construction with your personal needs and goals.

- If your primary focus is long-term value and sustainability: The unmatched repairability of a Goodyear welt makes it the definitive choice for footwear meant to last a decade or more.

- If your primary focus is all-weather durability: The superior water resistance and robust build provide excellent protection and reliability in varied conditions.

- If your primary focus is personalized comfort: You must be willing to invest in the break-in period, after which the shoe will offer a custom-molded fit that is difficult to replicate.

Ultimately, investing in a Goodyear welted shoe is a decision to prioritize craftsmanship and longevity over immediate convenience.

Summary Table:

| Feature | Benefit for Repairability |

|---|---|

| Two-Level Stitching | Outsole is stitched only to the welt, allowing for replacement without damaging the upper. |

| Separate Components | The upper/insole unit remains intact, preserving the shoe's core structure during resoling. |

| Cork Filling | Compresses to mold to your foot for comfort and is easily replaced with the sole. |

| Robust Construction | Built with a steel shank and multiple layers for a durable platform that withstands multiple repairs. |

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, Goodyear welted footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of resoleable shoes and boots designed for long-term value and superior comfort. Contact our team today to discuss how our manufacturing expertise can enhance your product line and provide your customers with footwear built to last.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- What are the advantages of rubber soles in sneakers? Unmatched Grip, Durability & Comfort

- What material is commonly used for the soles of non-slip footwear and why? Unlock the Secrets of Safe Footwear

- How do rubber and TPR soles compare in terms of water resistance? A Guide to Grip and Performance

- What were traditional shoe soles made from before rubber? The History of Leather Soles

- What are the advantages of rubber-soled shoes? Unlock Superior Grip & All-Day Comfort