At first glance, it seems counterintuitive, but certain types of electric hazard footwear are essential in explosive or flammable environments precisely because they manage the unseen risk of static electricity. These boots are specifically engineered to prevent the buildup and sudden discharge of static electricity from a worker's body, which could otherwise create a spark and ignite flammable vapors, dust, or materials.

The core principle is spark prevention. While standard "Electrical Hazard" (EH) boots insulate you from electricity, the correct footwear for flammable environments—Electrostatic Dissipative (ESD) boots—does the opposite. It safely grounds you, continuously bleeding off static charge to prevent a catastrophic spark.

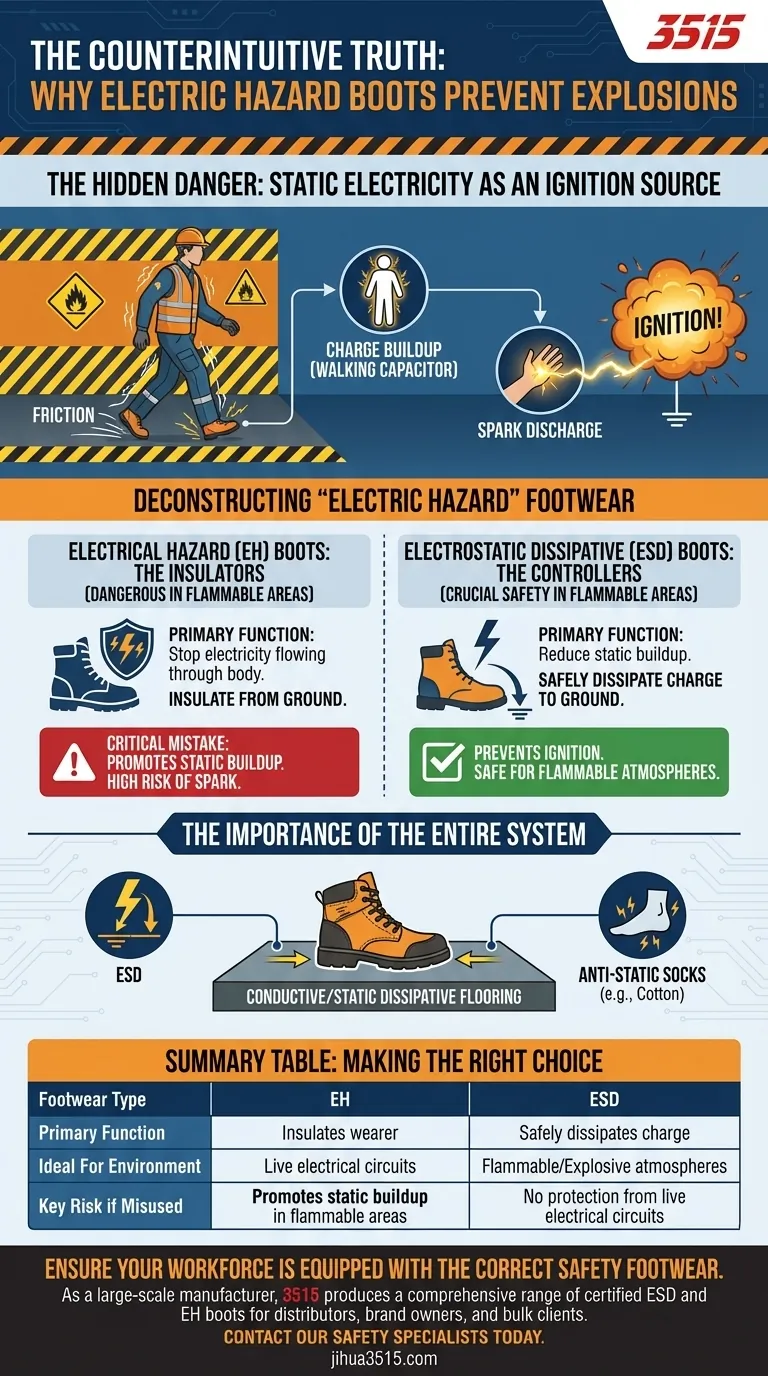

The Hidden Danger: Static Electricity as an Ignition Source

To understand the recommendation, you must first recognize that static electricity is a legitimate and dangerous ignition source in hazardous locations.

How Static Builds Up on the Body

As you walk and your clothing or footwear rubs against other surfaces, a static charge can build up on your body through friction. This is known as the triboelectric effect.

Without a safe path to the ground, this charge remains on your body, effectively turning you into a walking capacitor.

The Spark That Ignites

When your charged body comes close to a grounded object or one with a different electrical potential, the charge can leap across the air gap to equalize.

This sudden discharge is a visible spark. In an environment containing flammable gases, liquids, or combustible dust, this tiny spark is all that's needed to cause a fire or explosion.

Deconstructing "Electric Hazard" Footwear

The term "electric hazard boots" can be misleading because it covers two distinct categories of protection that serve opposite functions. Choosing the wrong one for your environment is a critical safety failure.

Electrical Hazard (EH) Rated Boots: The Insulators

Standard EH-rated boots are designed to protect the wearer from shock by open electrical circuits. They have a sole and heel that are non-conductive.

Their primary function is to stop electricity from flowing through your body by isolating you from the ground.

Electrostatic Dissipative (ESD) Boots: The Controllers

ESD footwear (also called Static Dissipative or SD) is designed to reduce the buildup of static electricity.

These boots contain a special material in the sole that allows the static charge to safely and slowly travel from your body, through the boot, and into the grounded floor. This prevents the charge from accumulating to a level that could produce a spark.

Common Pitfalls and Key Considerations

Simply mandating "electric hazard boots" is not enough. Understanding the distinction is crucial for ensuring real safety.

The Critical Mistake: Using EH Boots in Flammable Areas

Using standard, insulating EH boots in a flammable environment is extremely dangerous. Because they isolate the wearer from the ground, they actually promote the buildup of static electricity.

This dramatically increases the risk of a static discharge spark when the worker touches a grounded piece of equipment. For flammable environments, ESD-rated boots are the correct choice.

The Importance of the Entire System

ESD footwear is only one part of a static control system. For the boots to work effectively, the flooring in the work area must also be conductive or static dissipative, providing a clear path for the electrical charge to get to the ground.

Don't Forget Your Socks

The type of socks worn can impact static buildup. Materials like wool, silk, and nylon are prone to generating significant static charge.

It is recommended to wear cotton socks or specialized anti-static socks to ensure the ESD system works as intended.

Making the Right Choice for Your Goal

Selecting the correct footwear requires identifying the primary hazard you need to mitigate.

- If your primary focus is preventing ignition in flammable or explosive atmospheres: Use Electrostatic Dissipative (ESD) or Static Dissipative (SD) boots to safely discharge static electricity.

- If your primary focus is protecting workers from shock via live electrical circuits: Use Electrical Hazard (EH) rated boots to insulate the worker from the ground.

- If your primary focus is protecting sensitive electronic components from damage: Use Electrostatic Dissipative (ESD) boots to prevent static discharge from harming the electronics.

Understanding the specific function behind the safety rating ensures you are mitigating the correct risk, creating a truly safer work environment.

Summary Table:

| Footwear Type | Primary Function | Ideal For Environment | Key Risk if Misused |

|---|---|---|---|

| Electrical Hazard (EH) | Insulates wearer from ground | Live electrical circuits | Promotes static buildup in flammable areas |

| Electrostatic Dissipative (ESD) | Safely dissipates static charge | Flammable/Explosive atmospheres | No protection from live electrical circuits |

Ensure your workforce is equipped with the correct safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of certified ESD and EH boots for distributors, brand owners, and bulk clients. Our expertise ensures you get the right protection for explosive atmospheres, preventing costly accidents and ensuring compliance.

Contact our safety specialists today for a consultation on your specific needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture