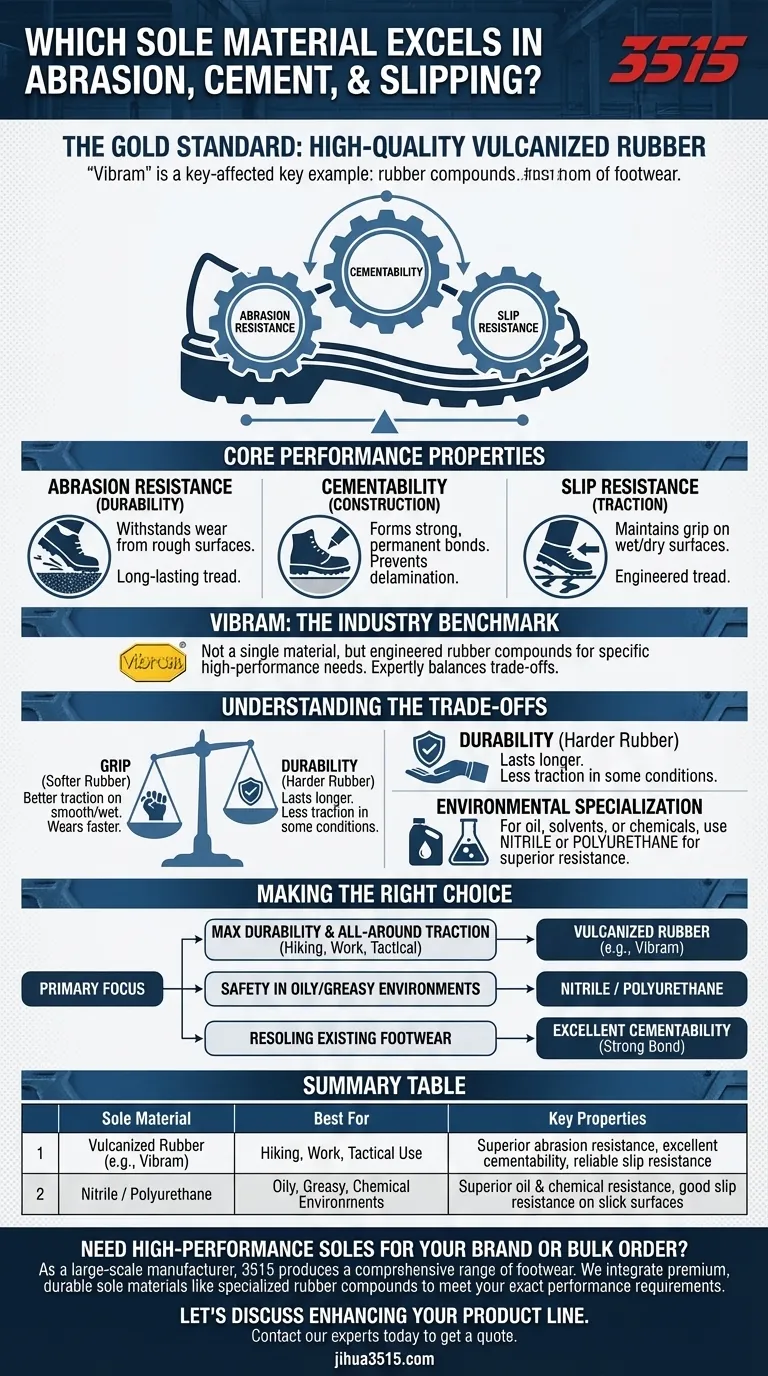

When selecting a sole for demanding applications, you need a material engineered to excel across multiple performance metrics. The most recognized solution that delivers excellent performance in abrasion resistance, cementability, and slip resistance is a high-quality vulcanized rubber compound, famously exemplified by the brand Vibram.

While many materials exist, specialized rubber compounds represent the gold standard for balancing extreme durability (abrasion resistance) with reliable traction (slip resistance) and the ability to be securely bonded to footwear (cementability).

What Defines a High-Performance Sole?

Understanding the core properties the user asked about—abrasion, cement, and slipping—is key to appreciating why certain materials are superior. These three factors form the foundation of a reliable, safe, and long-lasting shoe.

Abrasion Resistance (Durability)

This refers to the sole's ability to withstand wear from contact with rough surfaces. A sole with high abrasion resistance will not wear down quickly, maintaining its tread and protective structure for longer.

Dense, high-quality rubber compounds are specifically formulated to resist being worn away by friction, which is crucial for footwear used on pavement, rock, or industrial flooring.

Cementability (Construction)

In footwear, "cement" refers to the industrial adhesives used to bond the outsole to the midsole and upper. A material with good "cementability" can be properly prepared to form a strong, permanent bond.

This is a critical, often overlooked feature. Poor bonding leads to delamination—the sole peeling away from the shoe—which is a catastrophic failure in high-stakes environments.

Slip Resistance (Traction)

This is the sole's ability to maintain grip and prevent falls. It's a function of two things: the material's inherent coefficient of friction and the physical design of the tread pattern.

High-performance rubber provides excellent friction on a variety of surfaces, both wet and dry, while engineered lugs and channels in the tread help shed water and debris.

Vibram: The Benchmark in Sole Technology

The references specifically name Vibram because it has become the industry benchmark for the properties you require. However, it's important to understand what Vibram is.

More Than a Single Material

Vibram is not a single material but a brand that specializes in creating dozens of different high-performance rubber outsole compounds. Each compound is engineered for a specific purpose, from mountaineering to military applications.

An Engineered Balance

The company's success comes from its ability to expertly balance the trade-offs between different properties. They create compounds that are extremely durable and abrasion-resistant while still providing exceptional grip.

Understanding the Trade-offs

No single sole is perfect for every possible situation. The choice of material always involves balancing competing priorities.

Grip vs. Durability

This is the classic trade-off. A softer rubber compound will often provide superior grip, especially on smooth, wet surfaces, because it can conform better to microscopic imperfections. However, it will wear down much faster.

Conversely, a harder, denser rubber compound will last significantly longer but may offer less traction in certain conditions.

Environmental Specialization

While a high-end rubber compound like Vibram is an excellent all-around choice, some environments demand specialized materials.

For workplaces with oil, solvents, or chemicals, materials like nitrile or polyurethane are superior. These compounds are specifically formulated for oil resistance, preventing the sole from degrading and losing its integrity, a weakness of some standard rubbers.

Making the Right Choice for Your Goal

To select the best sole, match the material's strengths to your primary need.

- If your primary focus is maximum durability and all-around traction for hiking, work, or tactical use: Look for footwear featuring a sole from a specialist in high-performance rubber compounds, such as Vibram.

- If your primary focus is safety in oily, greasy, or chemical-rich environments: Prioritize soles made from specifically engineered materials like nitrile rubber or polyurethane that offer superior oil resistance.

- If your primary focus is resoling existing footwear: Ensure the replacement sole is known for excellent cementability to guarantee a strong, reliable bond that will not fail under stress.

Ultimately, choosing the right sole is about matching the material's engineered properties to the demands of your environment.

Summary Table:

| Sole Material | Best For | Key Properties |

|---|---|---|

| Vulcanized Rubber (e.g., Vibram) | Hiking, Work, Tactical Use | Superior abrasion resistance, excellent cementability, reliable slip resistance |

| Nitrile / Polyurethane | Oily, Greasy, Chemical Environments | Superior oil & chemical resistance, good slip resistance on slick surfaces |

Need High-Performance Soles for Your Brand or Bulk Order?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, and we can integrate premium, durable sole materials like specialized rubber compounds to meet your exact performance requirements.

Let's discuss how we can enhance your product line with soles built for durability, safety, and reliability.

Contact our experts today to get a quote

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job