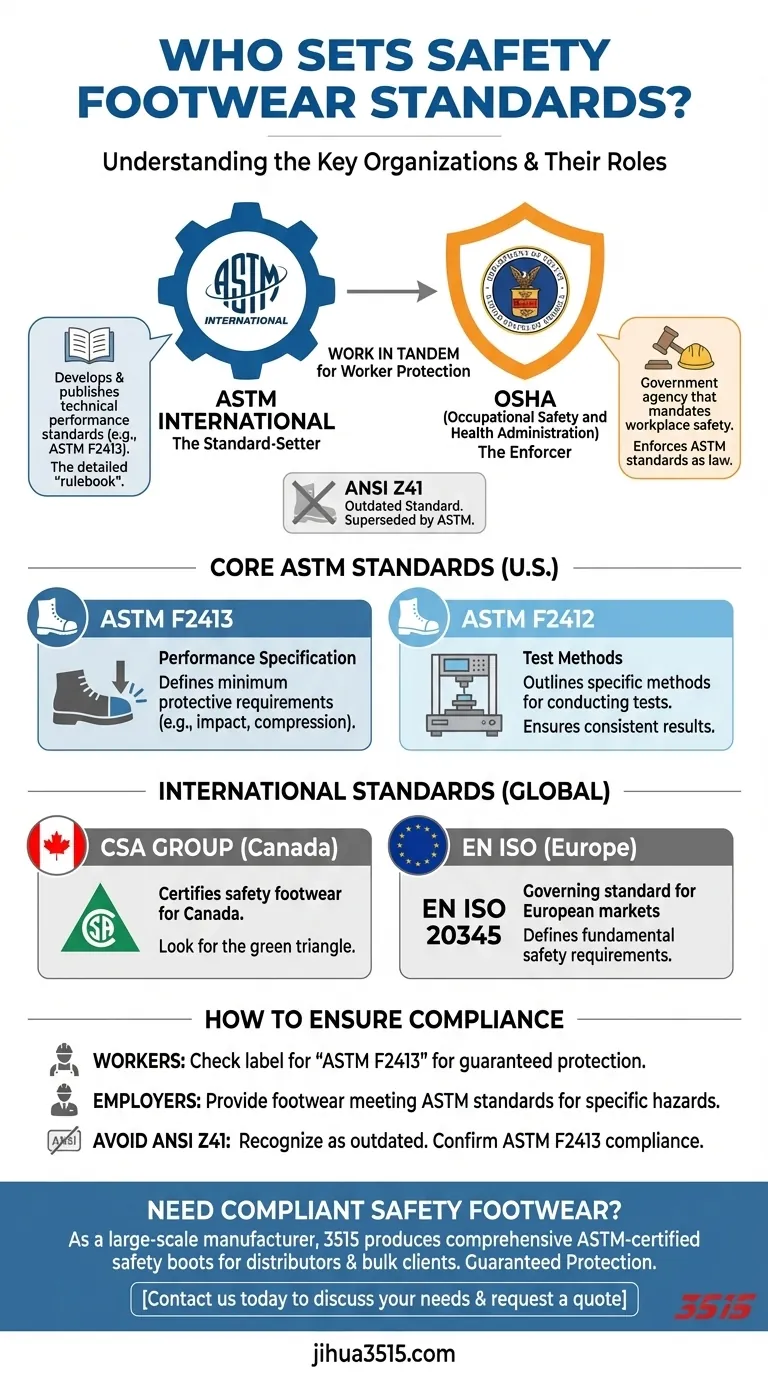

In the United States, the primary organization that develops the technical standards for safety footwear is ASTM International, while the Occupational Safety and Health Administration (OSHA) is the government agency that mandates its use in the workplace. These two organizations work in tandem to ensure worker protection.

The core relationship is simple: ASTM International writes the detailed rulebook on what makes a shoe "safe," and OSHA enforces that rulebook, requiring employers to provide footwear that meets those specific standards.

The Key Players in U.S. Footwear Safety

To understand safety ratings, you must first understand the role each organization plays. They are not competitors, but rather different parts of a single safety system.

ASTM International: The Standard-Setter

ASTM International, formerly the American Society for Testing and Materials, is the technical body that develops and publishes voluntary consensus standards.

For safety footwear, their standards are the definitive benchmark for performance. They detail exactly how a boot must be built and tested to earn a safety rating.

OSHA: The Enforcer

The Occupational Safety and Health Administration (OSHA) is a U.S. government agency. Its mission is to ensure safe and healthful working conditions.

OSHA doesn't write its own footwear testing standards from scratch. Instead, it incorporates the ASTM standards into its mandatory Personal Protective Equipment (PPE) guidelines, giving them the force of law in the workplace.

The Role of ANSI

You may also see references to the American National Standards Institute (ANSI). Historically, ANSI set the primary standard for safety footwear (ANSI Z41).

However, this standard has been superseded. The current governing standard is from ASTM, so always look for the ASTM rating on modern footwear.

Understanding the Core ASTM Standards

The labels inside your work boots refer to specific ASTM standards that define their protective capabilities. Knowing what they mean is crucial for selecting the right gear.

ASTM F2413: The Performance Specification

This is the most important standard you will see. ASTM F2413 specifies the minimum performance requirements for protective footwear.

If a boot is labeled "ASTM F2413," it means it has been certified to meet the baseline requirements for features like impact and compression resistance in the toe area.

ASTM F2412: The Test Method

This standard, ASTM F2412, outlines the specific methods for testing safety footwear.

It defines exactly how to conduct tests for impact, compression, electrical hazard resistance, and other protective features. This ensures that a boot rated in one facility is tested the same way as a boot rated in another.

A Note on International Standards

While ASTM and OSHA are the key players in the U.S., other organizations set the standards for different regions. This is important to know if you work internationally or are sourcing global equipment.

CSA Group (Canada)

In Canada, safety footwear is certified by the CSA Group (Canadian Standards Association). You will see a distinct green triangle or other CSA logos on compliant footwear.

EN ISO (Europe)

Across Europe, the governing standard is EN ISO 20345. This standard serves a similar function to ASTM F2413, outlining the fundamental safety requirements for protective footwear.

How to Ensure Your Footwear is Compliant

Understanding these organizations and standards allows you to verify the protection you're getting.

- If you are a worker in the United States: Look for a label inside the tongue or cuff of the boot that explicitly states it conforms to ASTM F2413.

- If you are an employer: Your responsibility under OSHA is to ensure the PPE you provide meets these established ASTM standards for the specific hazards present.

- If you see a reference to ANSI Z41: Recognize this as an outdated standard and confirm that your footwear meets the current ASTM F2413 specification for guaranteed compliance.

Knowing what these labels mean empowers you to make an informed choice and select footwear that provides proven protection.

Summary Table:

| Organization | Role | Key Standard/Function |

|---|---|---|

| ASTM International | Standard-Setter | Develops technical specs (e.g., ASTM F2413) |

| OSHA | Enforcer | Mandates use of ASTM standards in the workplace |

| CSA Group | Canadian Standard | Certifies footwear for the Canadian market |

| EN ISO | European Standard | Defines requirements for European markets (EN ISO 20345) |

Need compliant safety footwear that meets ASTM standards?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety boots and shoes for distributors, brand owners, and bulk clients. We ensure every pair meets the rigorous testing standards for impact, compression, and other hazards, providing guaranteed protection for your workforce.

Contact us today to discuss your safety footwear needs and request a quote.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

People Also Ask

- What is the primary function of medical safety protective shoes? Essential Foot Protection in Oral Clinical Settings

- What makes safety Wellington boots essential for worker safety? Unmatched Protection for Wet & Hazardous Work

- Why is the material integrity of safety footwear important in mining? Protect Workers from Toxic Chemical Extraction

- What specific hazards are professional safety shoes designed to prevent? Safeguard Your Workers from Workplace Injuries

- Why is industrial-grade PPE the most critical safety factor? Secure Your Site with the Final Line of Defense

- What is the logic for using industrial-grade protective footwear in diabetic care? Maximize Safety and Mobility

- What are the new categories introduced in EN ISO 20345:2022? S6 & S7 for True Waterproof Protection

- What is the necessity of professional protective gear for special populations? Ensure Safe Exercise and Joint Stability