The simplest test tells you everything. You should waterproof your work boots when you notice that water no longer beads up and rolls off the surface. This is the clearest sign that the protective barrier has worn down. As a rule, it's also wise to treat them seasonally, ideally in late summer or early fall, to prepare the boots for incoming rain and snow.

Waterproofing is not a one-time feature but an essential maintenance task. It's a proactive measure to preserve the boot's structural integrity, prevent damage to the materials, and protect your own health and comfort on the job.

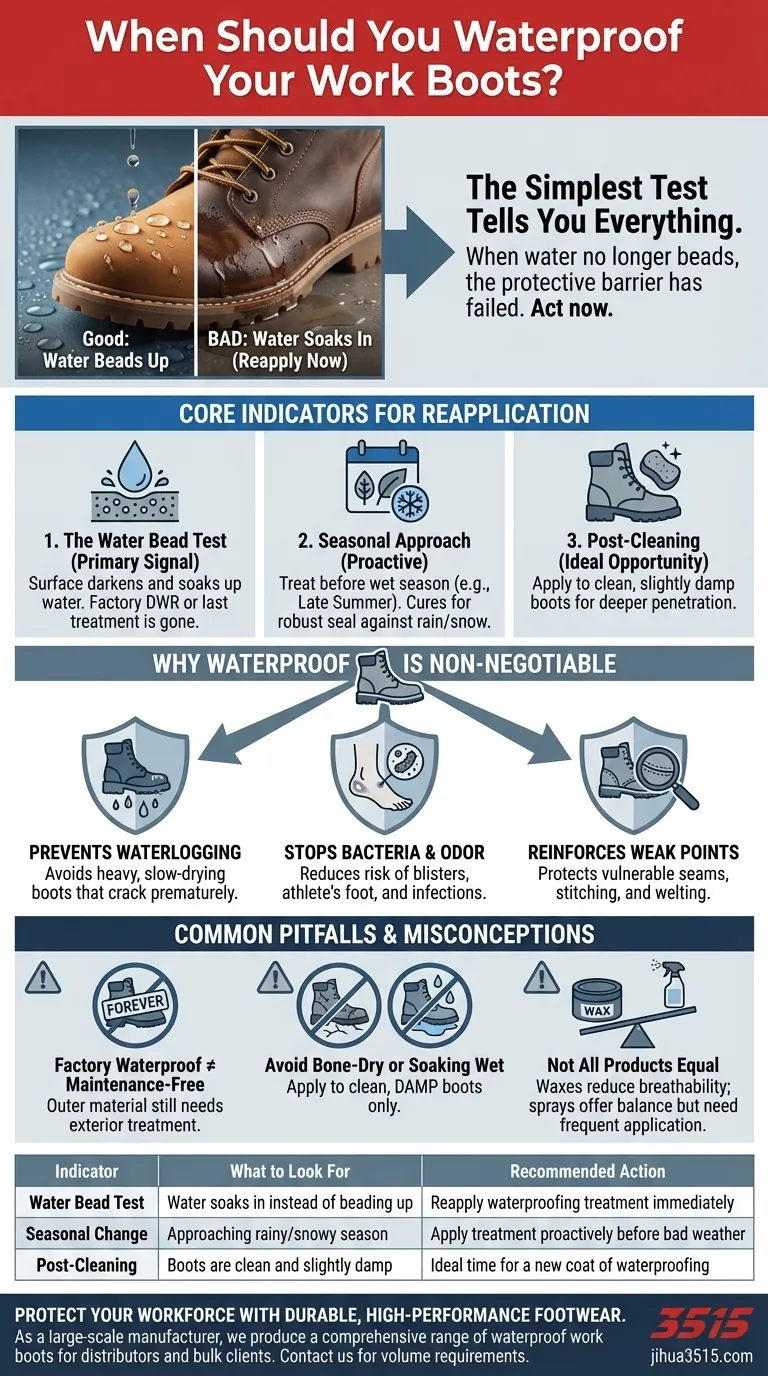

The Core Indicators for Reapplication

Deciding when to waterproof isn't about guesswork; it's about observation. Your boots will give you clear signals that their defenses are low and it's time for you to intervene.

The Water Bead Test: Your Primary Signal

The most reliable indicator is how the boot's surface handles water. When new or freshly treated, water should form distinct beads and roll off.

When you see water starting to darken the material and soak in rather than beading up, the factory DWR (Durable Water Repellent) finish or your last treatment has failed. This is your cue to act.

The Seasonal Approach: Preparing for a Downturn

Proactive maintenance is always better than reactive repair. Treating your boots during a dry, warm period, like late summer, prepares them before the wet season begins.

This ensures the waterproofing product can cure properly, creating a robust seal that’s ready for the first day of rain, slush, or snow.

Post-Cleaning: The Ideal Opportunity

You should reapply waterproofing products to clean boots. Dirt, dust, and grime can prevent the treatment from penetrating the material and creating an effective seal.

After giving your boots a thorough cleaning, it is the perfect time to apply a new coat of waterproofing while the boot is still slightly damp. This moisture helps draw the treatment deeper into the leather or fabric.

Why Regular Waterproofing Is Non-Negotiable

Failing to maintain your boot's water resistance has consequences that go far beyond just having damp feet. It affects the lifespan of your gear and your ability to work safely and comfortably.

Protecting Your Investment from Waterlogging

When leather or synthetic uppers become saturated, a process called waterlogging, they get heavy and take a long time to dry. Repeated cycles of soaking and drying can cause leather to stiffen, crack, and fail prematurely.

Preventing Blisters, Bacteria, and Odor

Damp boots are a breeding ground for bacteria and fungi. This not only leads to unpleasant odors but also significantly increases your risk of blisters, athlete's foot, and other skin infections.

Reinforcing Inherent Weaknesses

Even the most well-constructed boots have potential points of failure. Seams, stitching, and the area where the upper connects to the sole (welting) are common areas for water to seep in. Waterproofing treatments add a critical layer of protection to these vulnerable spots.

Common Pitfalls and Misconceptions

Understanding the nuances of waterproofing will ensure you get the best results and avoid common mistakes that can compromise your boot's performance.

"Factory Waterproof" Doesn't Mean "Maintenance-Free"

Many high-quality boots come with a built-in waterproof membrane or liner (e.g., Gore-Tex). While this inner layer keeps your foot dry, it doesn't stop the outer material from getting soaked.

Treating the exterior prevents the boot from becoming waterlogged, heavy, and cold. It maintains the boot's breathability and overall performance.

Applying to Soaking Wet or Bone-Dry Boots

Waterproofing products work best when applied to clean, damp boots. If the boot is too dry, the product may not penetrate deeply. If it's soaking wet, the product can't bond effectively.

Not All Waterproofing Products Are Equal

Heavy waxes and greases offer maximum water resistance but can significantly reduce a boot's breathability, which may be an issue in warmer weather. Lighter sprays and creams offer a better balance of protection and breathability but may require more frequent application.

How to Apply This to Your Job

Your specific work environment and priorities should dictate your waterproofing strategy.

- If your primary focus is working in consistently wet conditions (e.g., plumbing, landscaping): You need a boot with a waterproof liner and you must reapply an external treatment as soon as you notice water failing to bead.

- If your primary focus is general construction with occasional wetness: A seasonal application before the rainy season, combined with the water bead test, is a perfectly sufficient strategy.

- If your primary focus is preserving expensive leather boots: Integrate waterproofing with your regular leather conditioning routine to keep the material supple, prevent cracking, and maintain its natural water resistance.

Ultimately, maintaining your work boots is a simple discipline that pays you back every day in comfort, safety, and performance.

Summary Table:

| Indicator | What to Look For | Recommended Action |

|---|---|---|

| Water Bead Test | Water soaks in instead of beading up | Reapply waterproofing treatment immediately |

| Seasonal Change | Approaching rainy/snowy season (e.g., late summer) | Apply treatment proactively before bad weather |

| Post-Cleaning | Boots are clean and slightly damp | Ideal time for a new coat of waterproofing |

Protect Your Workforce with Durable, High-Performance Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of waterproof work boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear designed to withstand harsh conditions, ensuring durability, comfort, and long-term protection for your teams.

Let us help you equip your workforce with reliable gear. Contact us today to discuss your specific needs and volume requirements.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- Why is it necessary to equip operators with professional safety shoes in a flour milling workshop? Prevent Slip Hazards

- What safety boots are recommended for the oil and gas industry? Essential Features for Hazardous Sites

- Why is the use of professional safety shoes critical for injection molding? Prevent Injuries with High-Impact Footwear

- What were some early hazards that safety footwear addressed? A Guide to Essential Foot Protection