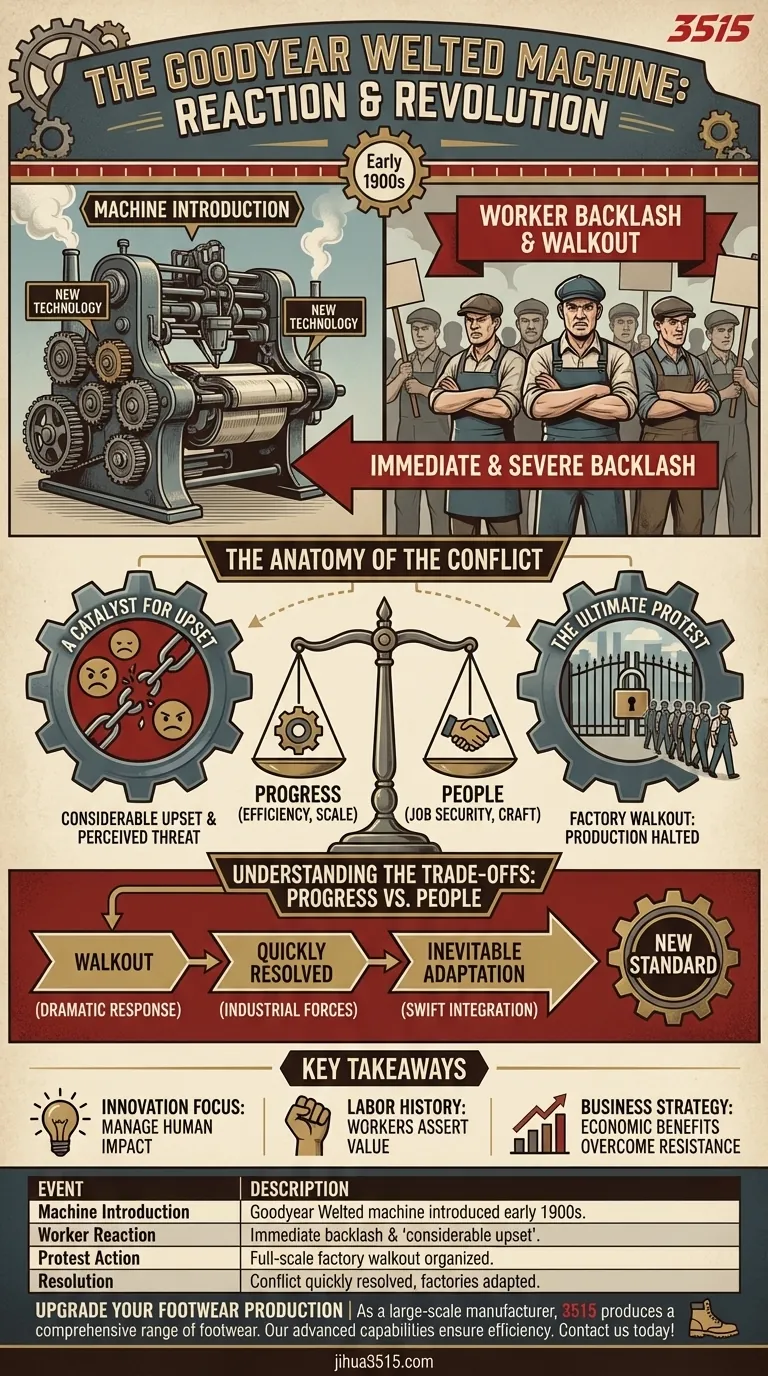

In short, the introduction of the Goodyear Welted machine was met with immediate and severe backlash from factory workers. At the turn of the 20th century, its arrival on the factory floor caused significant upset among operatives, which quickly escalated into a full-scale factory walkout in protest of the new technology.

The core takeaway is that while the Goodyear Welted machine ultimately revolutionized footwear production, its initial reception highlights a classic conflict: the tension between technological progress and the workforce's fear of displacement and change.

The Anatomy of the Conflict

The arrival of the Goodyear Welted machine was not a quiet evolution; it was a disruptive event. The immediate reaction from the people whose work it would forever change was one of profound opposition.

A Catalyst for Upset

The introduction of this machinery caused what sources describe as "considerable upset" among factory operatives. This wasn't minor grumbling but a significant emotional and professional response to a perceived threat.

The Ultimate Protest: A Factory Walkout

This widespread discontent quickly culminated in direct action. The factory operatives organized and executed a walkout, bringing production to a halt in a powerful statement against the mechanization of their craft.

Understanding the Trade-offs: Progress vs. People

This historical event serves as a perfect case study for the friction that often accompanies major technological leaps. The core of the conflict was not about the machine itself, but what it represented.

The Unspoken Fear of Displacement

For the factory operatives, the machine was likely seen as a direct threat to their job security. Automation, especially in that era, often led to a de-skilling of the workforce and a reduction in the number of skilled artisans required.

A Rapid, Yet Pivotal, Resolution

While the walkout was a dramatic response, the sources note that the issue was "quickly resolved." This suggests that the forces of industrialization and the efficiencies offered by the machine were too powerful to halt.

The Inevitable Adaptation

Following the resolution, the factory "soon adapted" to the new machines. This indicates a swift transition from protest to integration, establishing the Goodyear Welted machine as a new standard in manufacturing.

Key Takeaways from This Transition

The initial reaction to the Goodyear Welted machine offers timeless lessons about the nature of industrial and technological change.

- If your primary focus is on innovation: Understand that even the most beneficial technologies can face strong initial resistance if the human impact is not managed carefully.

- If your primary focus is on labor history: This event is a clear example of workers asserting their value and resisting changes that threaten their livelihood and craft.

- If your primary focus is on business strategy: The rapid adoption following the conflict demonstrates that the economic benefits of efficiency and scale often overcome initial implementation hurdles.

Ultimately, this episode reveals the recurring cycle of disruption, resistance, and eventual adaptation that defines technological progress.

Summary Table:

| Event | Description |

|---|---|

| Machine Introduction | Goodyear Welted machine introduced in early 1900s footwear factories. |

| Worker Reaction | Immediate backlash and "considerable upset" among skilled operatives. |

| Protest Action | Full-scale factory walkout organized to halt production. |

| Resolution | Conflict quickly resolved, with factories adapting to the new technology. |

Upgrade Your Footwear Production with Modern Manufacturing Solutions

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our advanced production capabilities ensure efficiency without compromising on quality. Let us help you navigate technological advancements in footwear manufacturing.

Contact us today to discuss your production needs!

Visual Guide

Related Products

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the basic steps to clean leather work boots? A 4-Step Guide to Preserve Your Investment

- What is the complete process for deep cleaning leather work boots? A Step-by-Step Guide to Preserve Your Investment

- How should new leather work boots be broken in? A Guide to Comfort and Durability

- Why might it be beneficial to pre-heat the boots before applying wax? Achieve Deeper, Longer-Lasting Protection

- How can you identify high-quality boots? A Guide to Durable Materials and Construction