The primary types of safety toe caps for oilfield work boots are steel, composite, and aluminum. Each is engineered to meet established safety standards but offers a distinct balance of protection, weight, and environmental resistance tailored to different job requirements on site.

The choice between steel, composite, and aluminum toe caps is not about which is "best" overall, but which provides the right trade-offs between maximum impact resistance, all-day comfort, and resilience to environmental factors specific to your role in the oilfield.

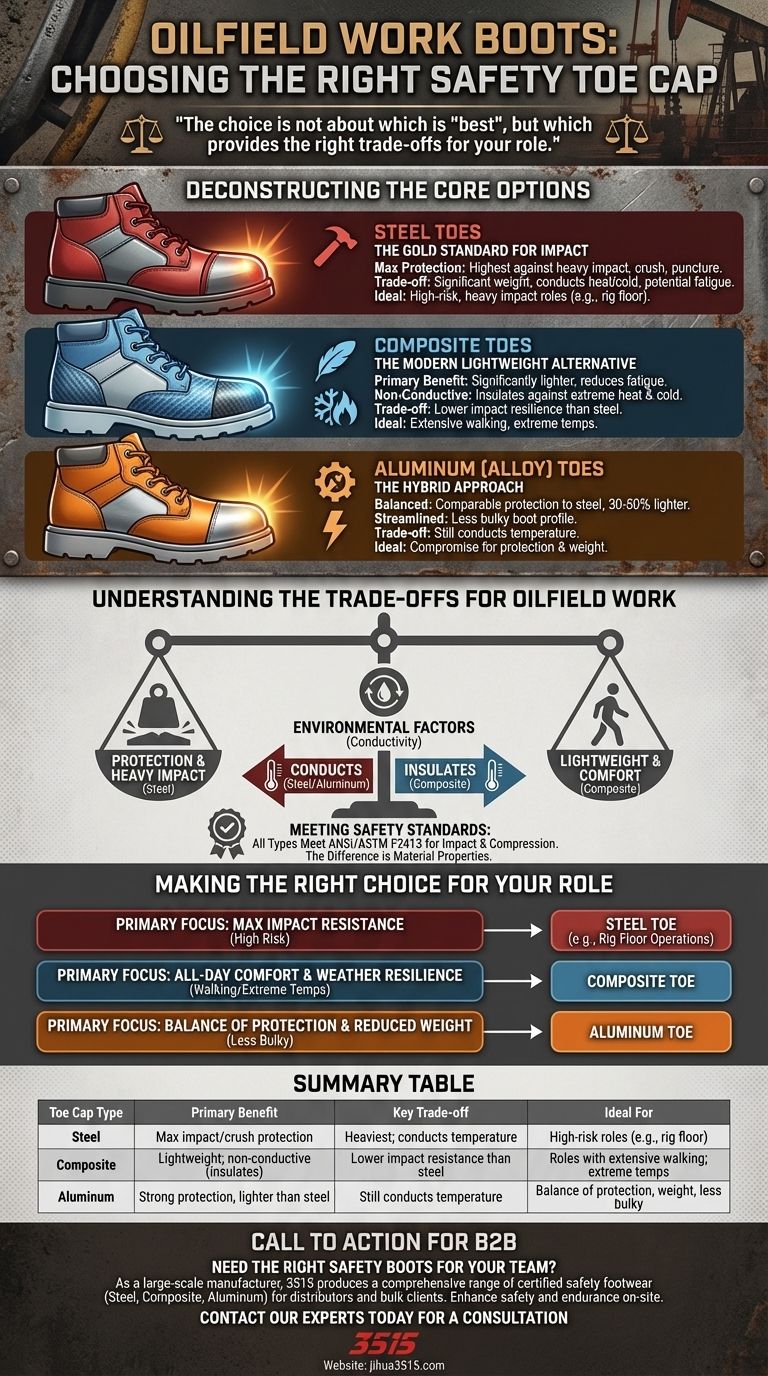

Deconstructing the Core Options

Each material used for a safety toe cap brings a unique set of properties to the work boot. Understanding these is the first step in selecting the right gear for the demanding conditions of the oilfield.

Steel Toes: The Gold Standard for Impact Protection

Steel is the traditional choice for safety toes due to its exceptional strength. It offers the highest level of protection against heavy impacts, punctures, and crushing forces from equipment like pipes or tools.

This strength makes steel the go-to for roles with the highest risk of direct, heavy impact. However, this protection comes at the cost of significant weight, which can increase fatigue over long 12-hour shifts.

Composite Toes: The Modern Lightweight Alternative

Composite toe caps are crafted from non-metallic materials like carbon fiber, plastic, or Kevlar. Their primary advantage is being significantly lighter than steel, which greatly enhances comfort for workers who are constantly on their feet.

Because they are non-metallic, composite toes do not conduct heat or cold. This is a crucial benefit for maintaining comfort in the extreme temperatures often found in oilfield locations.

Aluminum (Alloy) Toes: The Hybrid Approach

Aluminum, or alloy, toes provide a middle ground between steel and composite. They offer comparable impact protection to steel but are significantly lighter, often weighing 30-50% less.

They are also thinner than composite toe caps, resulting in a more streamlined, less bulky boot. While they are metallic, their reduced weight makes them a popular compromise for workers seeking protection without the fatigue of steel.

Understanding the Trade-offs for Oilfield Work

Choosing the right toe cap means balancing competing priorities. What works for a derrickhand may not be ideal for a site supervisor who covers miles of ground each day.

Protection vs. Weight

The fundamental trade-off is between maximum protection and worker fatigue. Steel offers unparalleled defense against crushing and impact but is the heaviest option.

Composite and aluminum provide certified, reliable protection while drastically reducing boot weight, which directly translates to less strain on your feet, legs, and back over a long shift.

Environmental Factors and Conductivity

The oilfield is an environment of extremes. Composite toes are insulators, meaning they won't transfer frigid cold or blistering heat to your feet, a major advantage for both comfort and safety.

Steel and aluminum, being metals, will conduct temperature. While modern boot insulation mitigates this, it remains a key differentiator for those working outdoors in harsh climates.

Meeting Safety Standards (ANSI/ASTM)

It is critical to understand that all three types—steel, composite, and aluminum—are designed to meet the same ANSI/ASTM F2413 safety standards for impact and compression resistance. A certified composite toe boot has passed the same rigorous tests as a certified steel toe boot. The difference lies in their material properties, not their fundamental ability to protect you.

Making the Right Choice for Your Role

Your specific job function should dictate your choice. Consider your daily tasks, environment, and physical demands to select the optimal boot.

- If your primary focus is maximum impact resistance in a high-risk role (e.g., rig floor operations), steel toe remains the most trusted and robust option.

- If your primary focus is all-day comfort and weather resilience for a role involving extensive walking or exposure to extreme temperatures, composite toe is the superior choice for its lightweight and non-conductive properties.

- If your primary focus is a balance of strong protection and reduced weight with a less bulky fit, aluminum toe offers an excellent compromise between steel and composite.

Ultimately, the right work boot is a critical piece of personal protective equipment that enhances both your safety and your endurance on the job.

Summary Table:

| Toe Cap Type | Primary Benefit | Key Trade-off | Ideal For |

|---|---|---|---|

| Steel | Maximum impact/crush protection | Heaviest; conducts temperature | High-risk roles (e.g., rig floor) |

| Composite | Lightweight; non-conductive (insulates) | Lower impact resistance than steel | Roles with extensive walking; extreme temperatures |

| Aluminum | Strong protection, lighter than steel | Still conducts temperature | Balance of protection, weight, and a less bulky fit |

Need the Right Safety Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of oilfield work boots with steel, composite, and aluminum toe caps, ensuring your workforce has the optimal blend of protection, comfort, and durability.

Let us help you equip your team with footwear that meets stringent safety standards and enhances on-site endurance. Contact our experts today for a consultation and to discuss your specific requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are OSHA approved shoes? Understanding the Correct Standards for Workplace Safety

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Do snake bite boots work? Your Ultimate Guide to Effective Snake Bite Protection