The right footwear for a mechanic is a critical piece of personal protective equipment (PPE), designed to counter the specific hazards of a garage environment. The absolute minimum requirement is a safety boot with an oil-resistant and slip-resistant sole, as petroleum-based fluids can degrade standard rubber and create dangerous slipping hazards. However, a truly effective boot incorporates a complete system of protective features.

While an oil-resistant sole is the most-cited requirement, a mechanic's ideal footwear is a comprehensive safety system. It is engineered to protect against slips from various fluids, impacts from dropped tools, compression from heavy parts, and unseen electrical dangers.

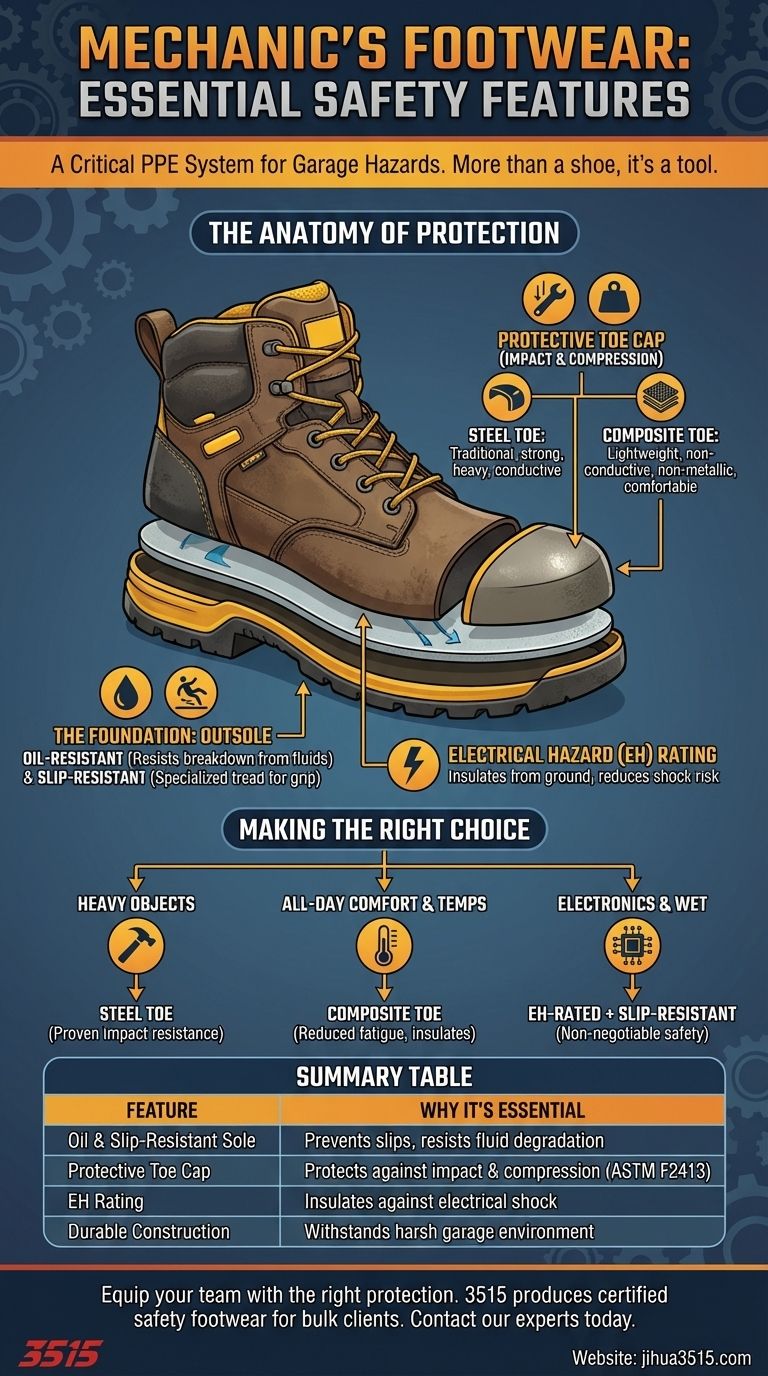

The Anatomy of a Mechanic's Safety Boot

To select the right footwear, you must understand how each component addresses a specific risk present on the shop floor. The boot is more than just a shoe; it's a tool for the job.

The Foundation: The Outsole

The outsole is your only point of contact with the floor, making its composition and design paramount. An oil spill or coolant leak can happen at any moment.

An oil-resistant sole is made from a rubber compound that will not break down, swell, or become brittle when exposed to petroleum products. This preserves the integrity and lifespan of the boot.

Equally important is slip-resistance. This is achieved through specialized tread patterns that channel liquids away from the sole's surface, ensuring the rubber maintains maximum contact with the floor for better grip.

Essential Impact and Compression Protection

The most obvious hazard in a shop is gravity. Heavy tools, transmissions, and engine parts can be dropped, posing a significant threat to your feet.

All mechanic's safety footwear must have a protective toe cap. These are rated by the American Society for Testing and Materials (ASTM) for their ability to withstand impact and compression forces.

You will typically choose between two main types: steel and composite. Both must meet the same minimum safety standards to be certified.

Guarding Against Electrical Hazards

Modern vehicles are complex electrical systems, and garages are filled with diagnostic equipment and power tools. This introduces the risk of electrical shock.

An Electrical Hazard (EH) rated boot is constructed with non-conductive materials and a sole that can withstand a specific electrical charge under dry conditions. This feature insulates you from the ground, significantly reducing the risk of completing a circuit and suffering a dangerous shock.

Understanding the Trade-offs: Steel vs. Composite Toe

The choice between a steel and composite toe cap often comes down to environment and personal preference, not a difference in fundamental protection.

Steel Toe: The Traditional Standard

Steel toe caps are the classic choice, known for their uncompromising strength. They can often be made with a slightly thinner profile than composite materials while providing the same level of protection.

However, steel is heavy and readily conducts temperature. In cold climates, a steel toe can make your feet feel colder, and in hot weather, it can retain heat.

Composite Toe: The Modern Alternative

Composite toes are made from non-metal materials like Kevlar, carbon fiber, or plastic. Their primary advantage is being significantly lighter than steel, which reduces foot fatigue over a long day.

They also do not conduct heat or cold, making them more comfortable in extreme temperatures. Because they are non-metallic, they will not set off metal detectors.

Making the Right Choice for Your Work

Ultimately, the best boot is one that meets the specific demands of your environment and keeps you safe and comfortable throughout your shift. Always look for the ASTM F2413 certification label inside the boot.

- If your primary focus is maximum protection against heavy falling objects: A steel toe boot offers proven, reliable performance and is the industry standard for impact resistance.

- If you prioritize all-day comfort and work in varied temperatures: A lightweight composite toe boot will reduce fatigue and keep your feet more comfortable without sacrificing certified safety.

- If you work extensively with vehicle electronics or in potentially wet conditions: An Electrical Hazard (EH) rated boot with a highly effective slip-resistant sole is a non-negotiable safety requirement.

Investing in the correct, certified footwear is the foundation for a safe and productive career in the garage.

Summary Table:

| Key Feature | Why It's Essential for Mechanics |

|---|---|

| Oil & Slip-Resistant Sole | Prevents dangerous slips on garage floors and resists degradation from petroleum-based fluids. |

| Protective Toe Cap (Steel/Composite) | Protects feet from impact and compression from heavy tools and parts. Meets ASTM F2413 standards. |

| Electrical Hazard (EH) Rating | Insulates against electrical shock from vehicle systems and power tools. |

| Durable Construction | Withstands the harsh, abrasive environment of a professional garage for long-lasting wear. |

Equip your team with the right protection from the ground up. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of professional boots, including the oil-resistant, slip-resistant, and EH-rated styles essential for mechanics. Let us help you source durable, comfortable, and fully compliant footwear for your workforce. Contact our experts today for a quote and to discuss your specific needs.

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Grain Leather Safety Boots for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- Why is it important to choose the right work boots for your job? Ensure Safety, Comfort, and Performance

- What safety boots are recommended for the construction industry? Ensure Maximum Protection on the Job Site

- How do composite toe boots handle extreme temperatures? Superior Thermal Insulation for Comfort

- What are pull straps and their variations in cowboy boots? A Guide to Mule Ears, Flush Pulls & More

- What features distinguish work boots from other types of cowboy boots? A Guide to Safety vs. Riding Performance

- What are the main types of safety toe boots? Choose the Right Protection for Your Job

- What are the cons of Cement Construction? The Hidden Costs of Glued Shoes

- What is the historical origin of engineer boots? From 1930s Railroads to Modern Icon