To earn a CE certification, motorcycle footwear is subjected to a precise battery of standardized tests. These mandatory evaluations measure a boot's resistance to impact abrasion, cutting, crushing forces, and structural failure, ensuring it provides a baseline level of protection in a crash.

Certification tests are not just a label; they are a systematic evaluation of a boot's ability to resist the specific forces of a motorcycle accident—abrasion, cutting, and crushing—while also ensuring its structural integrity for everyday use.

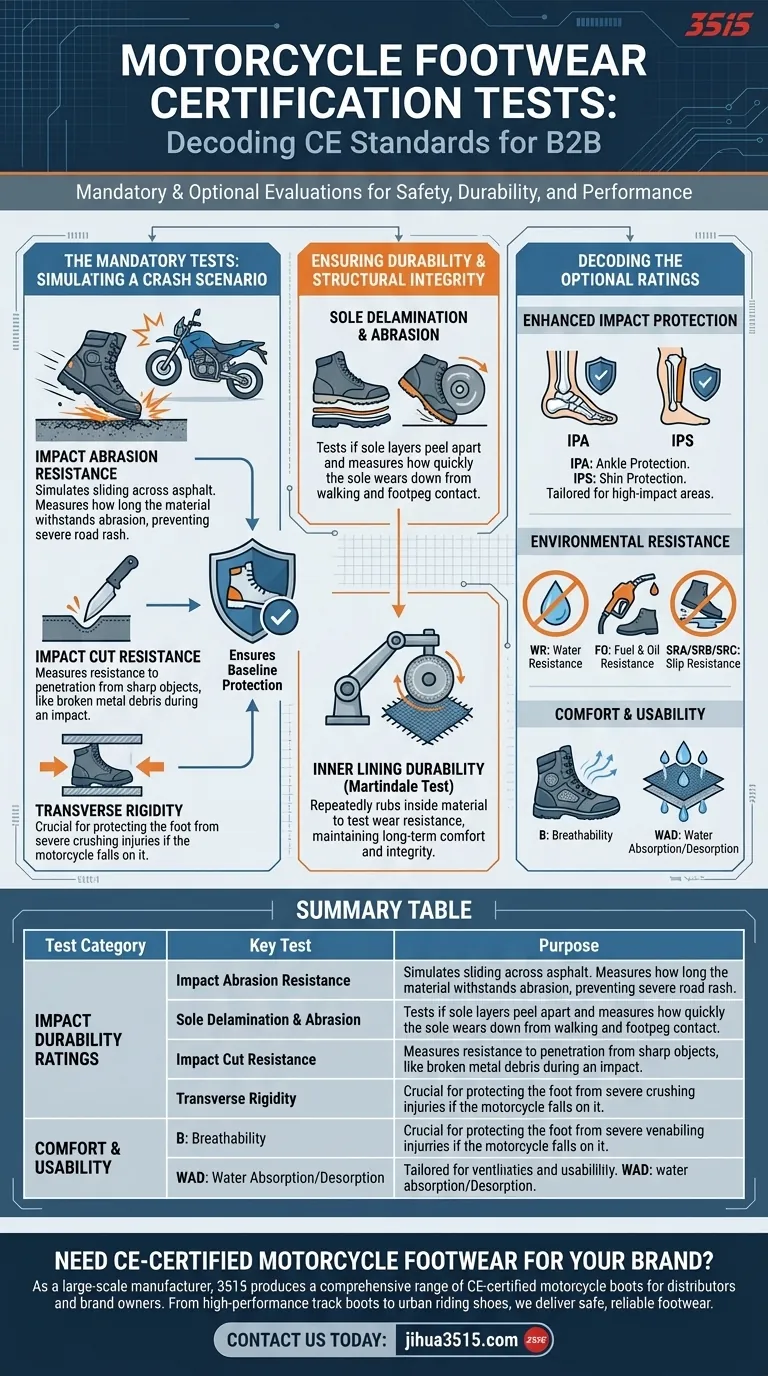

The Mandatory Tests: Simulating a Crash Scenario

The core certification requirements focus on three critical forms of protection that are essential in any motorcycle accident.

Impact Abrasion Resistance

This test simulates the boot sliding across asphalt during a fall. The material is tested to see how long it can withstand abrasion before wearing through, which is crucial for preventing severe road rash.

Impact Cut Resistance

A blade is dropped onto the boot material to measure its ability to resist penetration from a sharp object. This simulates an impact with broken metal or other debris during an accident.

Transverse Rigidity

This is one of the most important tests. The boot is compressed laterally to measure its resistance to being crushed. It is designed to protect your foot if the motorcycle falls on it, preventing severe crushing injuries.

Ensuring Durability and Structural Integrity

Beyond immediate crash protection, the tests also ensure the boot is well-constructed and won't fail during normal use.

Sole Delamination & Abrasion

Two separate tests evaluate the sole. The delamination test ensures the layers of the sole won't peel apart, while the abrasion test measures how quickly the sole wears down from walking and contact with footpegs.

Inner Lining Durability (Martindale Test)

The inside material of the boot is rubbed repeatedly to test its resistance to wear. This ensures the lining won't break down from the constant friction of your foot, maintaining comfort and integrity over time.

Decoding the Optional Ratings

In addition to the mandatory tests, manufacturers can submit boots for optional certifications. Passing these adds specific letters to the CE label, allowing you to choose footwear with features tailored to your specific needs.

Enhanced Impact Protection

Boots can be tested for additional impact absorption in key areas. Look for IPA for ankle protection and IPS for shin protection on the label.

Environmental Resistance

These ratings certify a boot's performance in different conditions.

- WR: Water Resistance

- FO: Resistance to fuel and oil on the sole

- SRA/SRB/SRC: Slip resistance on different surfaces

Comfort and Usability

Optional tests can also verify features related to rider comfort.

- B: Breathability

- WAD: Water absorption and desorption of the inner lining

Making the Right Choice for Your Ride

Understanding these tests allows you to read the certification label and select footwear that matches your specific riding style and environment.

- If your primary focus is track or aggressive street riding: Look for the optional IPA and IPS ratings for the highest level of impact protection.

- If your primary focus is all-weather commuting or touring: Prioritize boots with a WR rating for water resistance and B for breathability.

- If your primary focus is urban riding or workshop use: Consider FO (fuel/oil resistance) and SRA/SRB/SRC (slip resistance) to be critical for safety.

By understanding what these certification tests truly measure, you can confidently select footwear that provides the precise protection you need for your ride.

Summary Table:

| Test Category | Key Test | Purpose |

|---|---|---|

| Crash Protection | Impact Abrasion Resistance | Simulates sliding on asphalt to prevent road rash. |

| Impact Cut Resistance | Measures resistance to sharp object penetration. | |

| Transverse Rigidity | Tests crush resistance to protect feet from motorcycle weight. | |

| Durability & Integrity | Sole Delamination & Abrasion | Ensures sole layers stay intact and resist wear. |

| Inner Lining Durability (Martindale) | Checks lining wear resistance for long-term comfort. | |

| Optional Ratings | Enhanced Impact (IPA/IPS) | Provides extra ankle/shin protection for aggressive riding. |

| Environmental (WR, FO, SRA/SRB/SRC) | Certifies water, fuel/oil, and slip resistance. | |

| Comfort (B, WAD) | Verifies breathability and moisture management. |

Need CE-Certified Motorcycle Footwear for Your Brand or Retail Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of CE-certified motorcycle boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities ensure every pair meets rigorous standards for impact protection, durability, and rider comfort—whether you need high-performance track boots, all-weather touring models, or urban riding shoes.

Let us help you deliver safe, reliable footwear to your customers. Contact us today to discuss your manufacturing needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?