To ensure workers wear steel toe shoes, employers must implement a multi-layered system that combines a clear policy with consistent communication and enforcement. This involves identifying all hazardous areas, creating a mandatory written policy for those zones, training all employees and managers on the rules, and using visible signage as a constant reminder.

A safety policy is only as strong as its implementation. Simply stating a rule is not enough; you must build a comprehensive program that makes compliance straightforward, consistent, and a non-negotiable part of your workplace culture.

Foundational Steps: Policy and Risk Assessment

The first step is to move from an informal expectation to a formal, documented company policy. This creates clarity and legal standing for enforcement.

Start with a Thorough Risk Assessment

Before writing any rules, you must identify every area where foot protection is necessary. This is your foundation.

Common high-risk environments include construction sites, warehouses, factories, assembly areas, and auto repair shops. Look for specific hazards like heavy items that could fall, large machinery, sharp materials on the floor, or persistently slippery surfaces.

Develop a Clear, Written Policy

Your policy must be unambiguous. It should state exactly what type of footwear is required (e.g., ASTM-rated steel toe boots) and where it must be worn.

This written document is the source of truth for all training, signage, and disciplinary actions. It removes guesswork for both employees and managers.

Clearly Define "Hazardous Areas"

Use physical markers, like painted lines on the floor or distinct doorways, to define the boundaries where protective footwear becomes mandatory.

This makes the rule easy to follow. An employee knows that crossing a specific line means they must be wearing the correct PPE.

Driving Compliance Through Communication and Reinforcement

A policy that exists only on paper is ineffective. You must actively and continuously communicate the requirements to everyone in the organization.

Conduct Initial and Ongoing Training

Educate all managers and workers on the safety rules. Explain why the policy exists by showing examples of potential injuries.

Training shouldn't be a one-time event. Revisit the topic in safety meetings and during new employee onboarding to keep it top of mind.

Install Visible Safety Signage

Place clear, simple-to-understand signs at all entrances and exits of the designated hazardous areas.

These signs act as a final, immediate reminder for anyone entering the space, reinforcing the training and formal policy.

Ensure Leadership Buy-In

Managers and supervisors must lead by example. If a manager walks through a hazardous area without the proper footwear, it immediately undermines the entire policy.

Leadership must also be empowered and expected to enforce the rule consistently with their direct reports.

Addressing Common Hurdles to Compliance

Even with a perfect policy, human factors can create resistance. Proactively addressing these issues is key to a successful program.

The Challenge of Comfort and Fit

The most common reason for non-compliance is discomfort. Modern protective footwear comes in many styles, weights, and fits.

Consider offering a reimbursement program or partnering with a specific vendor to give employees options. An employee is far more likely to wear footwear they helped choose.

The Cost Factor

Protective footwear can be expensive, which can be a barrier for some employees. The company must decide on a clear policy for who covers the cost.

Many employers provide a voucher or allowance for safety shoes to remove cost as a reason for non-compliance and demonstrate their commitment to safety.

The Need for Consistent Enforcement

A policy that is enforced for some but not others will quickly fail. All employees, from the newest hire to the most senior manager, must be held to the same standard.

Establish a clear, tiered system for violations that is applied fairly and consistently across the board.

Making Your Safety Policy Effective

Your ultimate goal determines how you approach these steps. Use your objective as a guide.

- If your primary focus is minimum compliance: A written policy, clear signage, and basic training are the essential, non-negotiable steps.

- If your primary focus is preventing all foot injuries: Go further by implementing a footwear allowance program to improve comfort and a consistent enforcement plan to ensure no exceptions.

- If your primary focus is building a true safety culture: Involve employees in the risk assessment and footwear selection process, and ensure leadership consistently models the correct behavior.

A successful safety program is an active, ongoing commitment, not a one-time task.

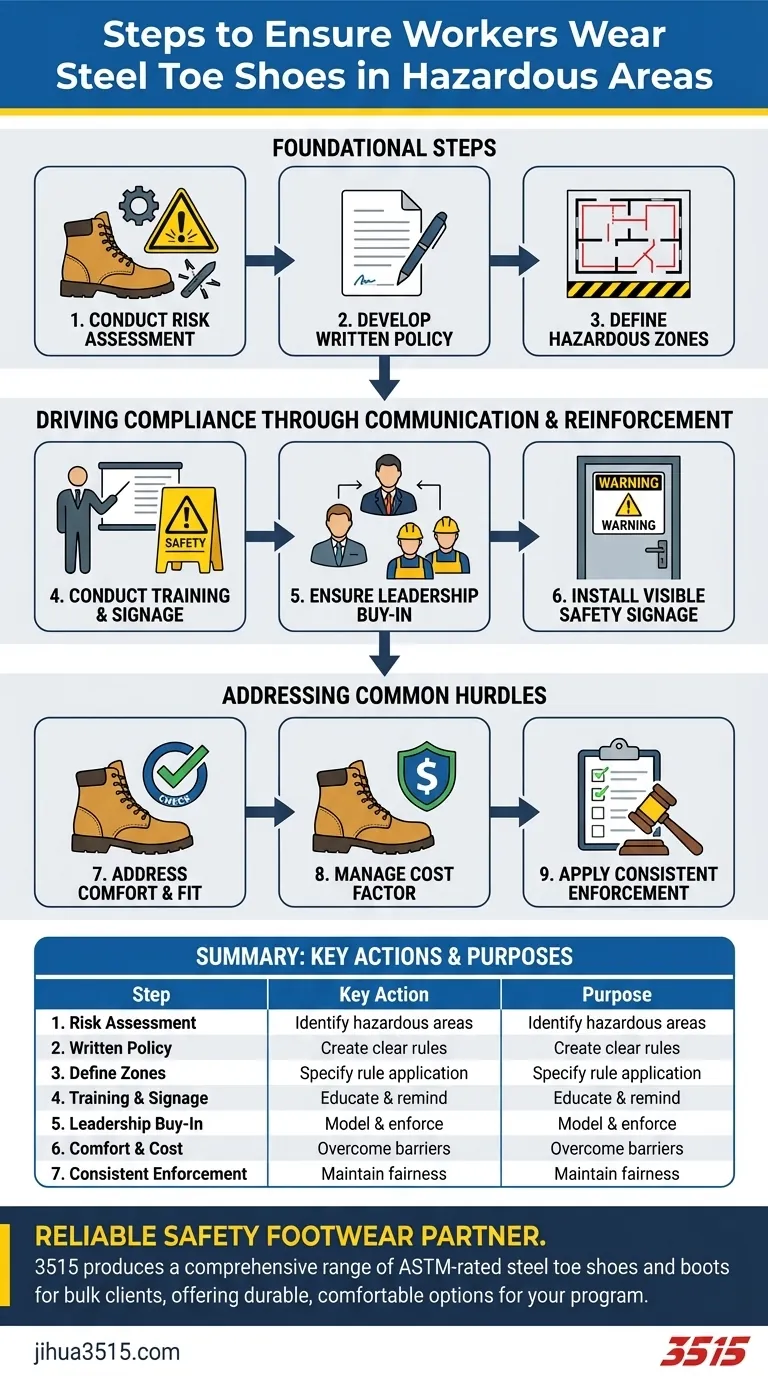

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Conduct Risk Assessment | Identify all hazardous areas requiring foot protection |

| 2 | Develop Written Policy | Create clear, enforceable rules for PPE use |

| 3 | Define Hazardous Zones | Use physical markers to specify where rules apply |

| 4 | Provide Training & Signage | Educate staff and post visible reminders |

| 5 | Ensure Leadership Buy-In | Managers must model and enforce compliance |

| 6 | Address Comfort & Cost | Offer footwear allowances to overcome barriers |

| 7 | Apply Consistent Enforcement | Maintain fair, tiered consequences for violations |

Need a reliable supplier for your company's safety footwear program? As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-rated steel toe shoes and boots for distributors, brand owners, and bulk clients. We offer durable, comfortable options to support your compliance and safety culture goals. Contact us today to discuss volume pricing and custom solutions for your workforce.

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Premium KPU Athletic Safety Shoes for Wholesale

People Also Ask

- Why is the use of steel-toe safety footwear critical during the maintenance of sugar factory press chains? Protect Your Team

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?

- What is the primary function of reinforced steel toe caps in industrial safety shoes? Protect Workers from Stone Impacts

- What is the purpose of front hardeners in safety shoes? Essential Protection for Construction & Welding

- How do safety shoes with reinforced toe protection and puncture-resistant midsoles serve as a physical barrier?