The most critical factors workers must consider when choosing footwear are the specific hazards of their work environment, followed by the shoe's durability, protective features, and all-day comfort. You must first identify the risks—such as falling objects, slippery surfaces, or sharp materials—and then select a shoe with the specific safety features designed to mitigate those exact threats. This decision is a foundational component of professional safety.

Choosing the right work footwear is not a matter of preference; it is a critical risk assessment. The single most important principle is to let the specific hazards of your job dictate the protective features of your shoe, ensuring your gear is perfectly matched to your environment.

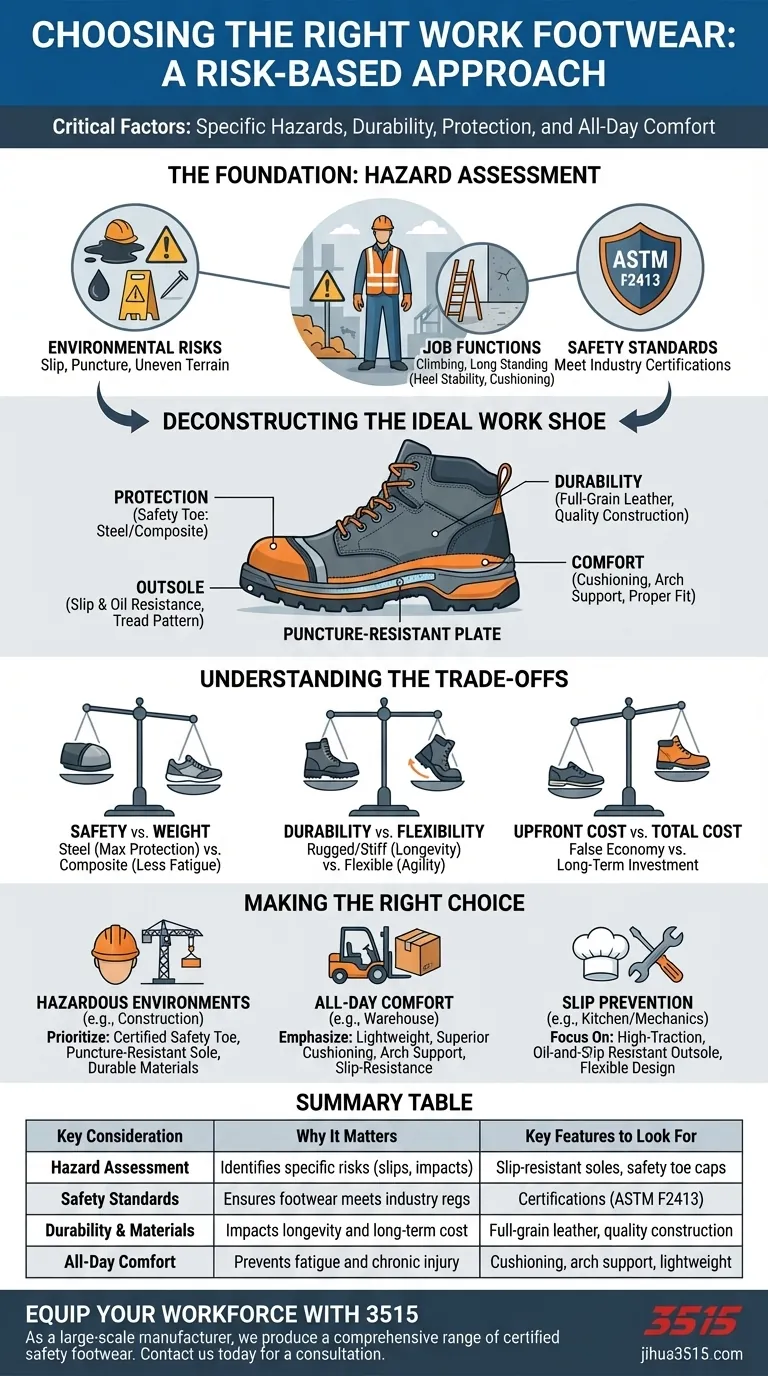

The Foundation: A Thorough Hazard Assessment

Before you can select the right shoe, you must deeply understand the environment you work in. Every feature of a work boot is designed to solve a specific problem, and identifying your problems is the essential first step.

Identify Environmental Risks

The most obvious hazards often come from the environment itself. Look for risks like wet or oily surfaces that demand slip-resistance, uneven terrain requiring ankle support, or the presence of sharp objects like nails that necessitate puncture-resistant soles.

Analyze Your Specific Job Functions

Consider the physical demands of your daily tasks. If your job involves climbing ladders, you need a defined heel for stability. If you stand on hard concrete all day, cushioning and arch support become paramount to prevent long-term fatigue and injury.

Understand Your Industry's Safety Standards

Many professions have regulatory safety standards for footwear (e.g., ASTM F2413 in the US). These standards specify requirements for impact resistance, compression resistance, and electrical hazard protection. Always ensure your chosen footwear meets or exceeds the required standards for your trade.

Deconstructing the Ideal Work Shoe

Once you have assessed your risks, you can evaluate a shoe's features to see if they meet your needs. Quality work footwear is an integrated system of protection, durability, and support.

Protection is Non-Negotiable

The primary purpose of a safety shoe is protection. A safety toe cap is the most common feature, which can be made of steel, lighter-weight composite materials, or aluminum alloy. Other vital features include puncture-resistant plates in the midsole and Electrical Hazard (EH) ratings for those working near live circuits.

The Critical Role of the Outsole

The outsole is your connection to the ground. Its material and tread pattern determine its effectiveness. Look for outsoles specifically rated for slip-resistance and oil-resistance. Different patterns are designed to channel away water or provide a better grip on rough surfaces.

Durability and Material Quality

High-quality materials like full-grain or bull-hide leather offer superior longevity and protection compared to synthetic alternatives. The shoe's construction method also plays a major role in its lifespan. A durable boot is not just a better investment; it is a more reliable piece of safety equipment.

Comfort for Long-Term Health

Comfort is not a luxury; it is a safety feature that prevents fatigue-related accidents and chronic injuries. A proper fit, a quality insole, and adequate arch support are crucial for anyone spending long hours on their feet. Features like two-zone lacing allow for a more customized and secure fit.

Understanding the Trade-offs

No single shoe is perfect for every situation. Choosing the right footwear often involves balancing competing priorities. Being aware of these trade-offs is key to making an informed decision.

Safety vs. Weight

Historically, maximum protection meant a heavy steel-toe boot. Modern composite-toe alternatives offer comparable impact protection at a significantly lower weight, reducing fatigue over a long shift. However, steel often provides superior resistance to extreme compression.

Durability vs. Flexibility

The most rugged, durable boots are often stiffer, which can limit agility. For roles that require constant crouching or climbing, a more flexible boot might be necessary, even if it means sacrificing some long-term durability.

Upfront Cost vs. Total Cost of Ownership

It can be tempting to choose a less expensive boot, but this is often a false economy. A cheaper shoe may wear out in months and provide inferior support, leading to higher replacement costs and potential health issues. A well-constructed boot is a long-term investment in both safety and finances.

Making the Right Choice for Your Profession

Your final decision should be a direct response to your hazard assessment. By focusing on your primary needs, you can easily eliminate unsuitable options and find the right footwear.

- If your primary focus is protection in a hazardous environment (e.g., construction): Prioritize a certified safety toe, a puncture-resistant sole, and durable, water-resistant materials.

- If your primary focus is all-day comfort on hard surfaces (e.g., warehouse work): Emphasize lightweight materials, superior cushioning, and excellent arch support while ensuring you still have a slip-resistant outsole.

- If your primary focus is slip prevention and agility (e.g., kitchens, mechanics): Your top priority should be a high-traction, oil-and-slip-resistant outsole paired with a flexible and comfortable design.

Investing in the right footwear is a direct investment in your daily safety and long-term well-being.

Summary Table:

| Key Consideration | Why It Matters | Key Features to Look For |

|---|---|---|

| Hazard Assessment | Identifies specific risks (slips, impacts, punctures) | Slip-resistant soles, safety toe caps (steel/composite) |

| Safety Standards | Ensures footwear meets industry regulations (e.g., ASTM F2413) | Certifications for impact, compression, electrical hazards |

| Durability & Materials | Impacts longevity and long-term cost | Full-grain leather, quality construction methods |

| All-Day Comfort | Prevents fatigue and chronic injury | Cushioning, arch support, proper fit, lightweight design |

Ready to equip your workforce with the perfect safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, comfortable, and certified work boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, ensuring your team has the right protection for their specific job hazards.

Contact us today for a consultation and discover how we can provide the ideal footwear solution for your business needs.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What does CE-approval indicate for safety boots? Your Guide to EU-Compliant Footwear Protection

- What are the core safety features of industrial safety shoes? Expert Guide for Bridge & Heavy Machinery Safety

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- What is the difference between side-zip and lace-up security guard safety boots? Speed vs. Perfect Fit

- What are the requirements for oilfield boots? Essential Safety & Durability Features