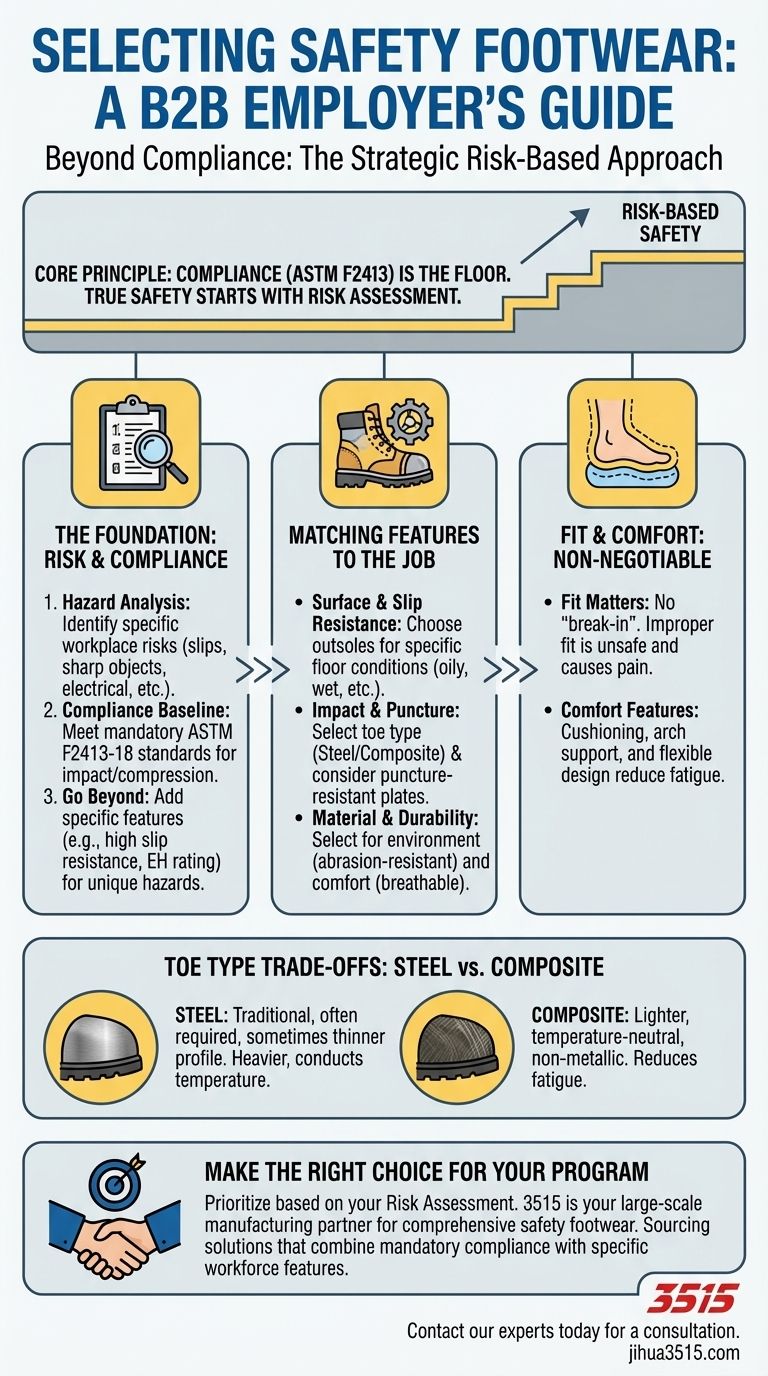

The most effective way to select safety footwear is to move beyond simply meeting a standard and instead base the decision on a formal workplace risk assessment. While compliance with standards like ASTM F2413 is the mandatory starting point, true safety is achieved by matching the shoe's specific protective features—such as slip resistance, toe type, and material—to the precise hazards your employees face every day.

The core principle of selecting safety footwear is this: Compliance is the floor, not the ceiling. A successful program is built on a thorough risk assessment that identifies the unique demands of your environment and the specific tasks your employees perform.

The Foundation: Risk Assessment and Compliance

Before you can choose the right boot, you must deeply understand the environment it will be used in. A systematic approach prevents costly and dangerous mistakes.

Start with a Hazard Analysis

A comprehensive risk assessment is the only reliable starting point. This process involves identifying every potential foot-related hazard in your workplace.

Consider risks like falling objects, sharp materials on the ground, slippery surfaces (water, oil, mud), electrical currents, and exposure to chemicals or extreme temperatures.

Understand the Compliance Baseline

The ASTM F2413-18 standard is the benchmark for safety footwear in the United States. It specifies the minimum performance requirements for protection against impact and compression for the toe area.

Ensuring any considered footwear meets this standard is a non-negotiable first step for legal compliance and foundational safety.

Go Beyond the Basic Requirements

Your risk assessment will reveal hazards that the base ASTM standard doesn't cover. This is where you must select footwear with additional, specific protective features.

For example, a roofer needs exceptional slip resistance, while an electrician needs shoes with an Electrical Hazard (EH) rating.

Matching Footwear to the Job and Environment

Once you've identified the hazards, you can align specific footwear features to mitigate them effectively.

Surface and Slip Resistance

The shoe's outsole is one of its most critical safety components. Analyze the primary walking surfaces your employees encounter.

Footwear for slick, oily, or wet floors requires a much higher slip-resistance rating than footwear used primarily on dry concrete or dirt. If slips persist with a certain type of shoe, you must upgrade to a higher-rated option.

Impact and Puncture Protection

The most well-known feature is the safety toe. The choice between steel and non-steel (composite) toes depends on your specific needs and workplace rules.

Beyond the toe, consider if employees are at risk of stepping on sharp objects like nails. If so, footwear with a puncture-resistant plate is essential.

Material, Durability, and Breathability

The materials of the shoe directly impact its longevity and the comfort of the wearer.

Durable leathers or synthetic materials are needed for abrasive environments. At the same time, breathability is crucial for preventing sweat and discomfort, which can lead to distraction and fatigue.

The Critical Factor: Employee Fit and Comfort

An uncomfortable safety shoe is an unsafe one. If footwear is painful or ill-fitting, employees are less likely to wear it correctly, or the discomfort itself can become a dangerous distraction.

Why Fit is Non-Negotiable

Unlike athletic shoes, heavy-duty safety footwear does not "break in" over time. An improper fit from the first day can cause stress on the shoe's structure, alter an employee's gait, and lead to chronic foot pain.

A proper fit ensures the safety features, like the toe cap, are positioned correctly to provide maximum protection.

Essential Comfort Features

Look for features that support employees who are on their feet all day.

Key elements include adequate cushioning to absorb shock, proper arch support to prevent strain, and a design that accommodates the specific work being done, such as flexible soles for jobs that require kneeling.

Understanding the Trade-offs: Steel vs. Composite Toes

The choice between toe cap materials is a common decision point for employers, with distinct advantages for each.

The Case for Steel Toes

Steel toes are the traditional standard for impact protection. They are often required by specific job site regulations. While they can be heavier, they sometimes offer a thinner, less bulky profile in the toe box of the boot.

The Case for Composite Toes

Non-metallic composite toes (made from materials like Kevlar, carbon fiber, or plastic) are significantly lighter than steel.

This reduces foot fatigue over a long shift. They also do not conduct heat or cold, making them more comfortable in extreme temperatures, and they will not set off metal detectors.

Making the Right Choice for Your Program

Your final decision should be guided by a clear understanding of your priorities, as identified in your risk assessment.

- If your primary focus is baseline compliance and impact protection: Ensure every shoe is rated to ASTM F2413-18 and select a toe type (steel or composite) that aligns with your site's rules.

- If your primary focus is addressing slip-and-fall hazards: Pay closest attention to the outsole's design and slip-resistance rating, matching it to the specific floor conditions your employees face.

- If your primary focus is maximizing employee adoption and comfort: Prioritize a professional fitting process and select footwear with features like light weight, cushioning, and breathability to reduce daily fatigue.

Ultimately, viewing safety footwear as a strategic investment in your employees' well-being is the surest path to a safer and more productive workplace.

Summary Table:

| Key Selection Factor | Why It Matters |

|---|---|

| Risk Assessment | Identifies specific workplace hazards (slips, impacts, etc.) for targeted protection. |

| ASTM F2413 Compliance | Mandatory baseline for impact/compression protection; the legal starting point. |

| Toe Type (Steel/Composite) | Steel offers traditional protection; composite is lighter and temperature-neutral. |

| Slip-Resistant Outsoles | Critical for preventing falls on oily, wet, or slick surfaces. |

| Proper Fit & Comfort | Uncomfortable shoes are unsafe; proper fit ensures correct use and reduces fatigue. |

Ready to equip your team with the right safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, designed to meet the specific hazards identified in your risk assessment.

We can help you source footwear that combines mandatory compliance with the specific features your workforce needs for maximum safety and comfort.

Contact our experts today for a consultation and discover how we can support your safety program.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- What are the advantages of water-based polyurethane spray coatings for safety shoe slip resistance? Enhanced Traction

- What core protections do industrial-grade safety shoes provide? Safeguarding Gemstone Miners Against Critical Hazards

- What are the benefits of wearing firefighter boots? Essential Protection for Extreme Conditions

- What are the main types of safety toe shoes? Choose the Right Protection for Your Job

- What replaced the ANSI Z41 standard? A Guide to Modern ASTM F2413 Safety Footwear

- Do yearly updates to ASTM safety standards affect the core protection thresholds? Understanding the Stable Safety Benchmark

- Why is it necessary to conduct regular maintenance and determine the service life of industrial safety footwear? Ensure Compliance and Safety

- What standards govern safety footwear ratings? Decode ASTM, EN ISO & CSA for Your Safety