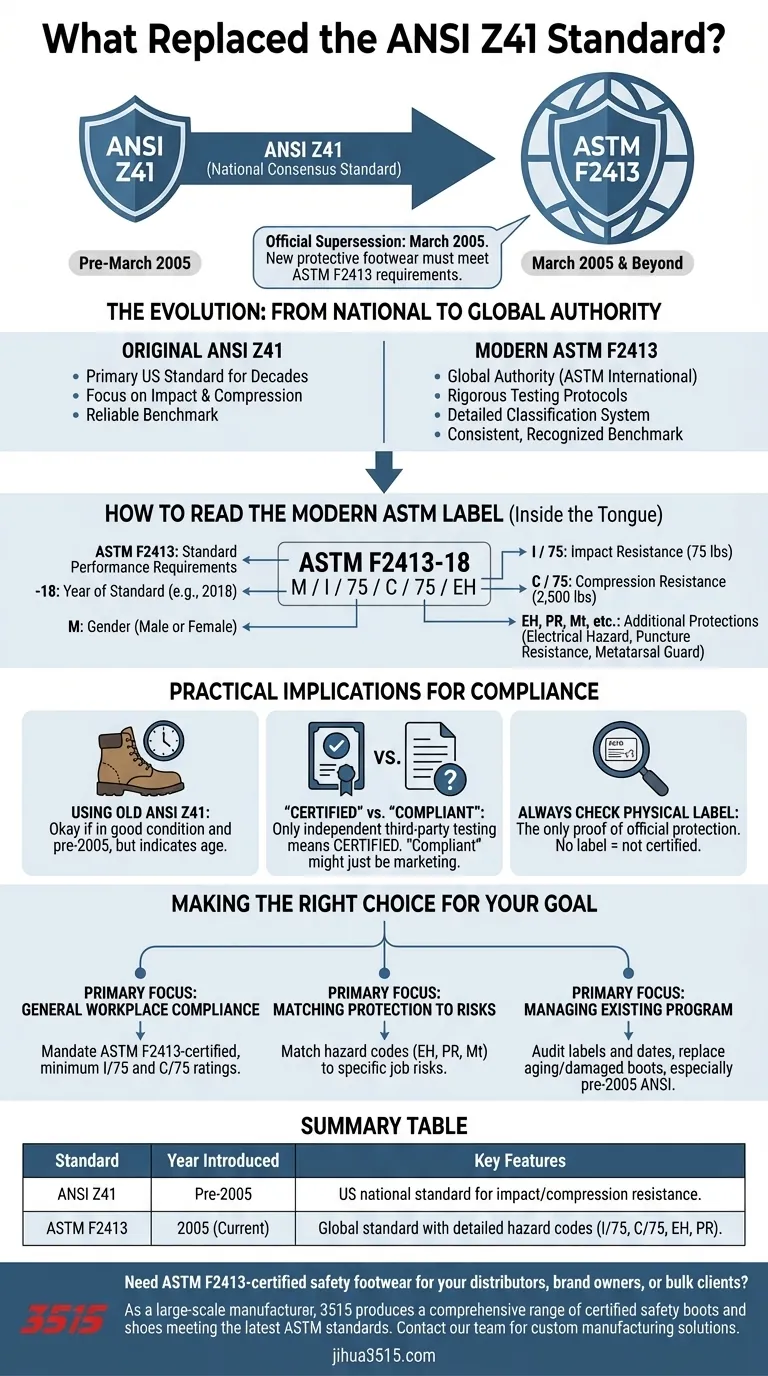

As of March 2005, the ANSI Z41 standard was officially superseded by ASTM F2413. This change marked a significant transition in how safety footwear is tested and certified in the United States. While footwear certified under the old ANSI standard may still be in use, all new protective footwear must now meet the ASTM F2413 requirements.

The shift from ANSI to ASTM represents a move from a national consensus standard to a more robust international one. The core safety principles remain, but the testing methods, certification process, and labeling are now governed by ASTM International to ensure a consistent, globally recognized benchmark for protective footwear.

The Evolution from ANSI Z41 to ASTM F2413

Understanding why the standard changed is key to appreciating its current importance. The transition was not about discarding old safety principles but about adopting a more comprehensive and standardized framework.

The Role of the Original ANSI Standard

For decades, ANSI Z41 was the primary US standard for personal protection footwear. Developed by the American National Standards Institute, it provided a reliable benchmark for impact and compression resistance in safety toes.

The Shift to a Global Authority

The move to ASTM International (formerly the American Society for Testing and Materials) consolidated safety footwear standards under a larger, globally recognized organization. This brought more rigorous testing protocols and a more detailed classification system.

What Formally Changed in 2005

In March 2005, the supersession became official. From that point forward, manufacturers were required to test and certify new safety footwear against the ASTM F2413 standard to be sold as protective footwear in the United States.

How to Read the Modern ASTM Label

One of the most practical outcomes of the change is a more detailed and informative labeling system. Every pair of ASTM-certified footwear has a label (typically sewn inside the tongue) that provides critical information at a glance.

The Core Line of Code

The label is formatted in a specific way. A typical first line will look like this: ASTM F2413-18.

- ASTM F2413: This identifies the footwear meets the performance requirements of the standard.

- -18: This number indicates the year of the standard's version (in this case, 2018) that the footwear conforms to.

The Protection Rating Line

A second line of code details the specific protections the shoe offers. A typical label might read: M / I / C / EH.

- M or F: This indicates the gender the footwear is designed for (Male or Female), as their testing criteria differ slightly.

- I: This signifies Impact Resistance. The number 75 (I/75) is the highest rating, meaning the toe cap can withstand a 75-pound impact.

- C: This signifies Compression Resistance. The number 75 (C/75) is the highest rating, meaning the toe cap can withstand 2,500 pounds of compression.

- EH, PR, Mt, etc.: These codes denote additional protections like Electrical Hazard (EH), Puncture Resistance (PR), or Metatarsal Guard (Mt).

Understanding the Practical Implications

This transition has direct consequences for employers and workers responsible for safety and compliance. Misunderstanding the standards can lead to inadequate protection.

Using Old ANSI Z41 Footwear

If a pair of safety boots was manufactured before March 2005, it may carry an ANSI Z41 label. As long as the footwear is in good, serviceable condition, it can still be used. However, it is a clear indicator of the footwear's age.

"Compliant" is Not the Same as "Certified"

Be wary of marketing language. True safety footwear has been independently tested and certified by a third-party laboratory to meet the ASTM standard. The term "compliant" may simply mean the manufacturer believes it meets the standard, without independent verification.

Always Check the Physical Label

The only way to be certain a piece of footwear provides official protection is to find the permanent ASTM label inside the shoe. If there is no label, it is not certified safety footwear.

Making the Right Choice for Your Goal

Selecting the correct footwear is a critical safety decision. Use the ASTM standard to guide your choice based on the specific hazards of your environment.

- If your primary focus is general workplace compliance: Mandate that all new safety footwear purchases are certified to the latest version of ASTM F2413 and have, at minimum, I/75 and C/75 ratings.

- If your primary focus is matching protection to specific risks: Look beyond the basic toe protection and match the hazard codes on the label (like EH, PR, or Mt) to the known risks of the job.

- If your primary focus is managing an existing footwear program: Audit current footwear by checking for the ASTM label and its date, and establish a clear policy to replace aging or damaged boots, especially any remaining pre-2005 ANSI-rated footwear.

By understanding the ASTM F2413 standard, you can confidently verify and select protective footwear that meets the highest benchmarks for modern workplace safety.

Summary Table:

| Standard | Year Introduced | Key Features |

|---|---|---|

| ANSI Z41 | Pre-2005 | US national standard for impact/compression resistance. |

| ASTM F2413 | 2005 (Current) | Global standard with detailed hazard codes (I/75, C/75, EH, PR). |

Need ASTM F2413-certified safety footwear for your distributors, brand owners, or bulk clients? As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and shoes. We ensure every pair meets the latest ASTM standards for impact, compression, and specialized hazards. Let us help you source reliable, compliant footwear—contact our team today for custom manufacturing solutions.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene