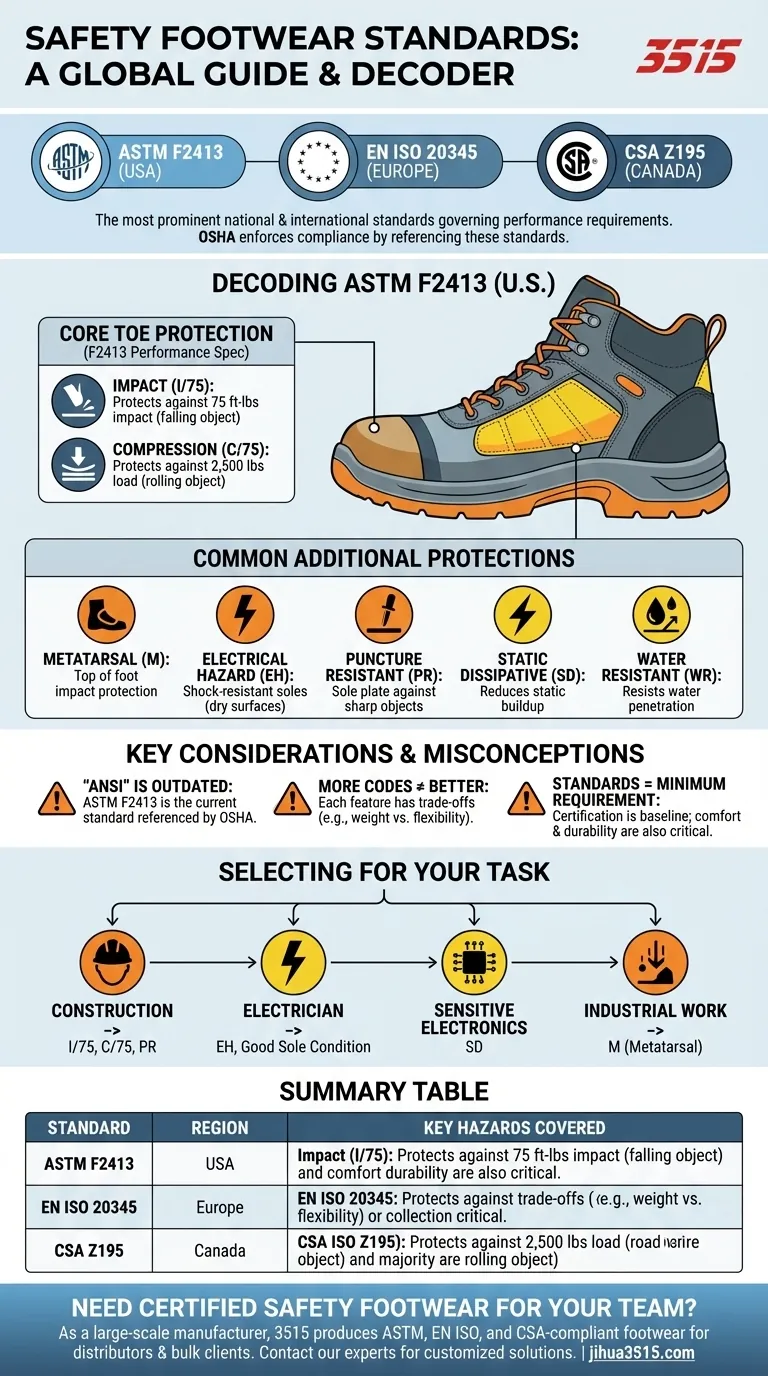

In short, safety footwear ratings are governed by national and international standards, with the most prominent being ASTM F2413 in the United States, EN ISO 20345 in Europe, and CSA Z195 in Canada. These standards establish the minimum performance requirements for footwear designed to protect against specific workplace hazards. Regulatory bodies like the U.S. Occupational Safety and Health Administration (OSHA) then enforce compliance by referencing these established standards.

The core challenge isn't just knowing the standards, but learning to decode the specific rating codes on a boot. These codes tell you exactly which hazards—from impact and compression to electrical shock—the footwear is certified to protect against.

The Global Landscape of Safety Standards

Understanding safety footwear begins with recognizing that standards are geographically specific. While the goal of protection is universal, the testing methods and labeling conventions differ significantly between regions.

The Role of Regulatory Bodies

Organizations like OSHA in the United States do not typically create their own standards for safety footwear. Instead, they incorporate standards developed by independent, consensus-based organizations.

OSHA's regulations mandate that employers ensure their employees use protective footwear when working in areas with a danger of foot injuries. They specifically reference the standards set by ASTM International.

Key International Standards

The three dominant standards you will encounter are:

- ASTM (United States): The American Society for Testing and Materials sets the primary standards used across the U.S.

- EN ISO (Europe): This is the harmonized European standard that all safety footwear sold in Europe must meet.

- CSA (Canada): The Canadian Standards Association develops the standards required for protective footwear in Canada.

Decoding the ASTM F2413 Standard (United States)

For anyone working in the U.S., the ASTM standards are the most critical to understand. The label on a safety boot provides a concise summary of its protective features.

The Foundation: ASTM F2412 vs. F2413

It's important to distinguish between two related standards. ASTM F2412 defines the test methods for foot protection, detailing how to perform impact, compression, and other tests.

ASTM F2413 is the performance specification. It dictates the minimum performance requirements that footwear must meet when subjected to the tests outlined in F2412. A boot is certified to ASTM F2413.

Core Toe Protection: Impact and Compression

The most fundamental ratings relate to the protective toe cap.

- Impact (I/75): This indicates the boot protects the toes from an impact of 75 foot-pounds. This simulates a heavy object falling on the foot.

- Compression (C/75): This shows the boot protects against a compressive load of 2,500 pounds, such as from a heavy object rolling over the foot.

Common Additional Protections

Beyond the toe cap, a boot can be rated for numerous other hazards:

- Metatarsal (M): Provides protection for the top of the foot (the metatarsal bones) from impact.

- Electrical Hazard (EH): The footwear is made with non-conductive, shock-resistant soles and heels, providing a secondary source of protection on dry surfaces.

- Puncture Resistant (PR): A puncture-resistant plate is built into the sole to protect against sharp objects like nails.

- Static Dissipative (SD): Reduces the buildup of static electricity by conducting it through the shoe to the ground.

- Water Resistant (WR): Indicates the footwear is designed to resist water penetration.

Understanding the Trade-offs and Common Misconceptions

Navigating these standards involves more than just reading labels. Recognizing outdated terms and prioritizing features are key to making an informed decision.

"ANSI-Rated" is an Outdated Term

You may still see footwear advertised as meeting "ANSI Z41" standards. This was the predecessor to ASTM F2413. While the performance requirements and labeling are virtually identical, ASTM F2413 is the current, official standard referenced by OSHA.

More Codes Don't Always Mean Better

A boot loaded with every possible rating is not automatically superior. Each additional feature can introduce trade-offs. For example, a puncture-resistant sole can make a boot heavier and less flexible. The goal is to match the boot's specific protections to the actual, known hazards of your environment.

Standards Are a Minimum Requirement

Certification to a standard is the baseline, not the finish line. It confirms the footwear passed specific, controlled tests. However, factors like material quality, durability, proper fit, and comfort are equally critical for all-day safety and performance.

How to Select the Right Footwear for Your Task

Use the hazard assessment of your job as a guide to prioritize the necessary ratings on your next pair of boots.

- If your primary focus is construction or heavy material handling: Your non-negotiable ratings are I/75 and C/75 for toe protection, and you should strongly consider PR for puncture resistance.

- If your primary focus is work as an electrician: You must seek out an EH rating and ensure the sole is in good condition with no embedded conductive materials.

- If your primary focus is working around sensitive electronics: SD footwear is essential to prevent static discharge that could damage components.

- If your primary focus is industrial work with falling objects: M (Metatarsal) protection offers a critical layer of safety beyond the standard toe cap.

By learning to read the language of these standards, you transform a confusing label into a clear guide for your personal safety.

Summary Table:

| Standard | Region | Key Hazards Covered |

|---|---|---|

| ASTM F2413 | United States | Impact (I/75), Compression (C/75), Metatarsal (M), Electrical Hazard (EH) |

| EN ISO 20345 | Europe | Basic safety requirements, Toe cap impact resistance, Energy absorption |

| CSA Z195 | Canada | Impact, Compression, Metatarsal, Puncture Resistance (PR) |

Need Certified Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM, EN ISO, and CSA-compliant safety footwear for distributors, brand owners, and bulk clients. We ensure your workforce is protected against specific workplace hazards with durable, certified boots and shoes.

Contact our experts today to discuss your safety footwear requirements and get a customized solution.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- What is the application value of lightweight safety shoes? Boost Comfort and Safety in Hybrid Workplaces

- What is the significance of SA 8000 and EMAS certification standards? Elevate Safety Shoe Manufacturing Quality

- What is the role of an industrial friction coefficient tester? Ensuring Slip Resistance for Safety Footwear

- Why is it necessary to clean safety boots and protective clothing immediately? Prevent Deadly Chemical Exposure Now

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- What should workers do before choosing safety footwear? Assess Workplace Hazards for Optimal Protection

- What biomechanical factors are essential in safety shoe outsole design? Expert Guide to Trip and Fall Prevention

- What factors affect the price of security guard safety boots? Key Insights for Smart Procurement