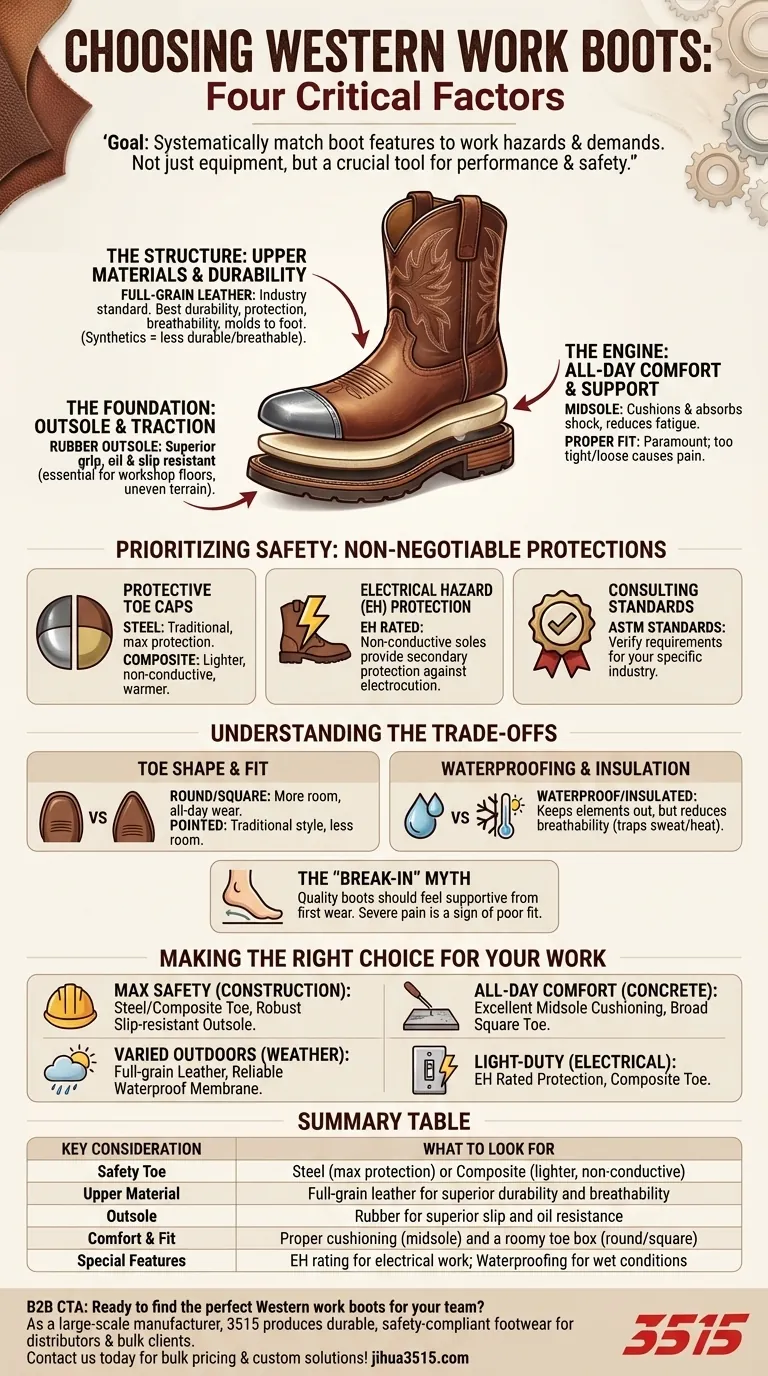

When choosing Western work boots, you must evaluate them based on four critical factors: safety features tailored to your job, the durability of the upper material, the traction provided by the outsole, and the overall fit and comfort for long hours. The right boot is not just a piece of equipment but a crucial tool for your daily performance and safety.

The goal is not to find the "best" Western work boot, but to systematically match the boot's specific features—from its toe protection to its outsole material—to the unique hazards and demands of your work environment.

Deconstructing the Boot: The Core Components

A work boot's performance is determined by the quality and purpose of its fundamental parts. Understanding these components allows you to assess a boot's suitability for your specific needs.

The Foundation: Outsole and Traction

The outsole is your primary point of contact with the ground, making its material and design critical for safety.

Most quality work boots use a rubber outsole. This material provides superior grip and is resistant to oil and slips, which is essential on workshop floors, construction sites, and uneven terrain.

The Structure: Upper Materials and Durability

The "upper" is the main body of the boot that covers your foot. Its material dictates the boot's longevity and protective capability.

Full-grain leather is the industry standard for a reason. It offers the best durability, protection, and breathability, molding to your foot over time for a custom fit.

Synthetic materials may lower the initial cost, but they typically offer less durability and breathability than genuine leather, making them less suitable for demanding, long-term use.

The Engine: All-Day Comfort and Support

Since you spend most of your day in your boots, comfort is not a luxury—it's a functional requirement.

The midsole provides cushioning and absorbs shock. A well-designed midsole reduces fatigue from long hours of standing or walking on hard surfaces like concrete.

Proper fit is paramount. A boot that is too tight or too loose will cause pain and potential injury, regardless of its other features.

Prioritizing Safety: Non-Negotiable Protections

Western work boots must meet the specific safety demands of your occupation. Style is secondary to function when hazards are present.

Protective Toe Caps: Steel vs. Composite

A safety toe protects you from impact and compression from heavy objects.

Steel toes offer the traditional, maximum level of protection. Composite toes, made from materials like carbon fiber or plastic, are lighter, don't conduct electricity, and won't get as cold in winter.

Electrical Hazard (EH) Protection

If you work near live electrical circuits, Electrical Hazard (EH) rated boots are essential.

These boots are designed with non-conductive soles and heels to provide a secondary source of protection against accidental electrocution.

Consulting Your Industry's Standards

Always verify the safety requirements for your job site or industry. Look for boots that meet specific ASTM International standards to ensure they are certified for the protection you need.

Understanding the Trade-offs

Choosing the perfect boot always involves balancing competing features. Being aware of these trade-offs helps you make an informed decision.

Toe Shape and Its Impact on Fit

The shape of the toe box affects both style and comfort.

Round and broad square toes offer the most room for your toes to spread naturally, making them ideal for all-day wear. Pointed toes, while traditional in style, are generally less suitable for a work environment.

Waterproofing and Insulation

Features like waterproofing are critical for wet environments, but they can come at a cost.

A waterproof membrane keeps water out but can also trap sweat and heat, reducing breathability. Similarly, insulation is vital for cold climates but will be uncomfortable in warm weather.

The Myth of the "Break-In" Period

While quality leather boots do have a break-in period as they conform to your feet, they should feel supportive and reasonably comfortable from the first wear.

Severe pinching, rubbing, or pain is a sign of a poor fit, not a boot that needs breaking in.

Making the Right Choice for Your Work

Your final decision should be guided by the primary demands of your daily tasks.

- If your primary focus is maximum safety on a construction site: Prioritize boots with a certified steel or composite toe and a robust, slip-resistant rubber outsole.

- If your primary focus is all-day comfort while walking on concrete: Look for a boot with excellent midsole cushioning and a broad square toe for maximum room.

- If your primary focus is working outdoors in varied weather: Select a boot made from full-grain leather with a reliable waterproof membrane.

- If your primary focus is light-duty work with electrical hazards: Ensure your boots are explicitly rated for Electrical Hazard (EH) protection, preferably with a composite toe.

By aligning the boot's construction with your daily demands, you invest not just in footwear, but in your long-term safety and comfort.

Summary Table:

| Key Consideration | What to Look For |

|---|---|

| Safety Toe | Steel (max protection) or Composite (lighter, non-conductive) |

| Upper Material | Full-grain leather for superior durability and breathability |

| Outsole | Rubber for superior slip and oil resistance |

| Comfort & Fit | Proper cushioning (midsole) and a roomy toe box (round/square) |

| Special Features | EH rating for electrical work; Waterproofing for wet conditions |

Ready to find the perfect Western work boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and safety-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots, ensuring you get the right combination of safety features, materials, and comfort for your specific industry needs.

Contact us today for bulk pricing and custom solutions!

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What protective features do professional Safety Shoes provide in shipyard environments? Maximize Worker Safety

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What is the function of impact-resistant toe caps in safety footwear? Protect Your Feet During Heavy Lifting

- What are the core advantages of using impact-resistant safety shoes in dairy farm mechanical work zones?

- How do Robotic Gait Systems verify the durability and safety of mass-produced safety boots? Ensure Unrivaled Performance in Extreme Conditions