Okay, so the user wants to know about slip-resistant work shoes. My initial thought is to just spit out the basics: material, tread pattern, and flexibility. But I know they're looking for more than a surface-level answer; they need to understand why these factors matter. They're investing in PPE to prevent injuries, and I need to deliver on that need.

My plan starts with a direct answer, then builds out the "why" by connecting specific outsole features to real-world workplace hazards like water, oil, and uneven surfaces. I'm going to lean on the references to pull out key materials (like rubber, gum rubber, and TPR) and tread features (deep lugs, multidirectional patterns).

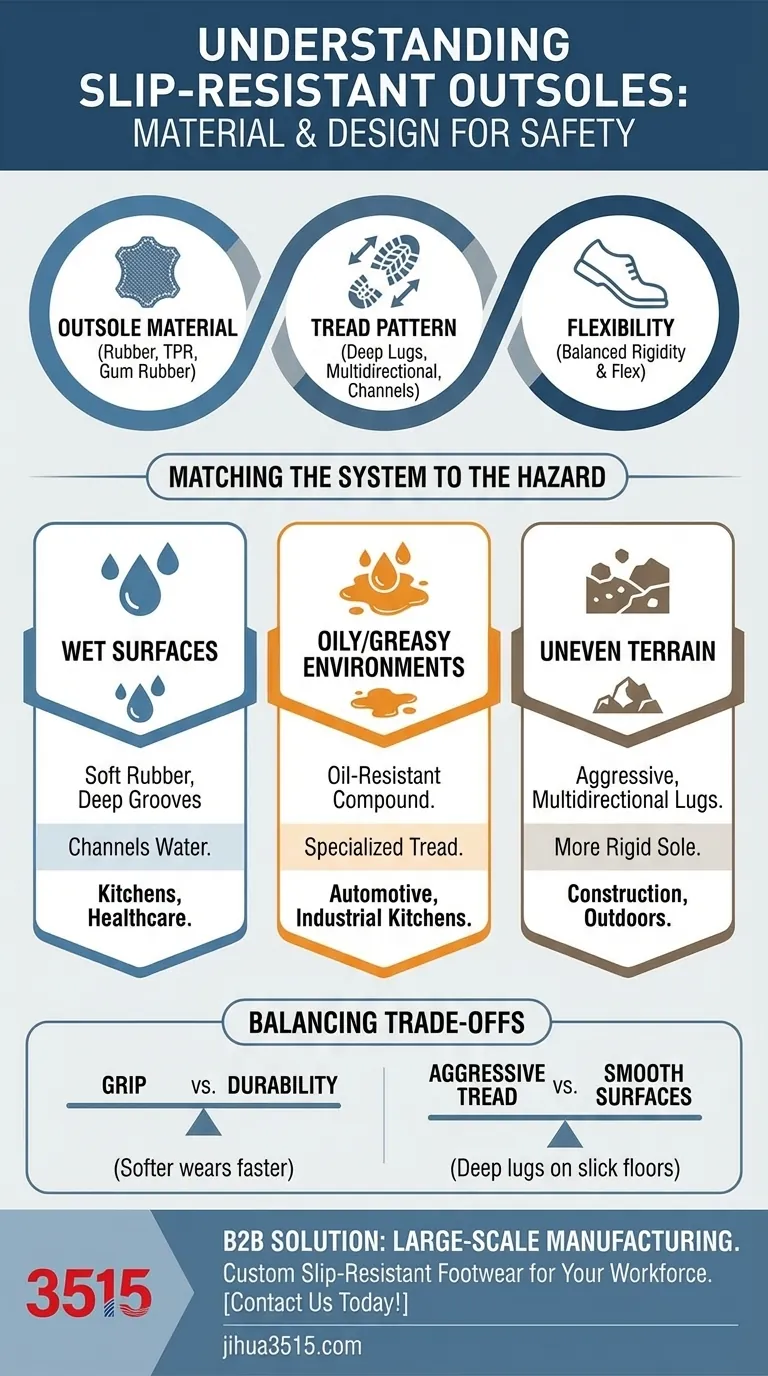

I need to structure this thoughtfully. The core is the connection between the shoe and the environment. This means a section explicitly linking outsole features to hazards. I'll include a takeaway box to hammer home the main point: there's no single "best" material, it's about matching the system (material + design) to the workplace.

Here's how I see it:

- Hook: Start strong and get right to the point: the material, tread, and flexibility.

- Core Takeaway Box: It's about matching the outsole system to the specific hazards.

- H2: Deconstructing the Outsole: Material and Design

- H3: Outsole Material: (Discuss rubber, TPR, and their resistance properties).

- H3: Tread Pattern: (Explain deep lugs, multidirectional patterns, and the idea of liquid channeling; mention the trip-hazard design from the references).

- H3: The Role of Flexibility: (Strike a balance between comfort and stability).

- H2: Matching the Shoe to the Hazard: (This is the meat of it).

- H3: For Wet Surfaces: (Rubber and deep grooves).

- H3: For Oily Surfaces: (Specific rubber compounds and chemical resistance).

- H3: For Uneven Terrain: (Multidirectional lugs and flexibility).

- H2: Understanding the Trade-offs: (Building trust and showing objectivity).

- H3: Aggressive Treads vs. Smooth Surfaces.

- H3: Durability vs. Grip: (Softer rubber can wear faster).

- H3: Slip Resistance vs. Other Safety Needs: (Steel toes, EH ratings, etc. from the references).

- H2: Making the Right Choice for Your Environment: (Actionable advice).

- Bullet points for kitchens/hospitals (oily/wet).

- Bullet points for construction (uneven, durability).

- Bullet points for healthcare/janitorial (mostly wet).

- Final Sentence: Empowering summary about making an informed safety decision.

I'm confident because the references give me a solid foundation. The distinction between the surface and deep needs is clear, and I can synthesize the information to provide helpful, actionable advice. Slip resistance is key, but the holistic approach is what sets the advice apart. Ultimately, I can give this user, a fellow expert, actionable advice for a complex problem. When evaluating slip-resistant work shoes, the most critical factors are the outsole's material composition, the depth and design of its tread pattern, and the shoe's overall flexibility. Materials like rubber and thermoplastic rubber (TPR) provide excellent grip, while deep, multi-directional lugs are designed to channel away liquids and bite into surfaces, ensuring stable footing in hazardous conditions.

The effectiveness of a slip-resistant shoe is not determined by a single feature, but by how the entire outsole system—its material, tread pattern, and flexibility—is engineered to counter the specific slip hazards of your work environment.

Deconstructing the Outsole: Material and Design

To make an informed decision, you must understand how the core components of an outsole work together to prevent slips and falls. Each element plays a distinct role in creating a safe and stable platform.

Outsole Material: The Foundation of Grip

The compound used for the outsole is the first line of defense against slips. Different materials are formulated to perform best on specific surfaces.

Common high-performance materials include natural rubber, gum rubber, and thermoplastic rubber (TPR). These are favored for their high coefficient of friction, which provides excellent grip and durability against abrasion and chemicals.

Tread Pattern: The Key to Traction

The design of the tread is what actively creates traction. A flat, smooth sole can easily hydroplane on a wet surface, but a well-designed tread prevents this.

Look for patterns that are deep and aggressive, with multidirectional lugs or channels. This design works by biting into the walking surface while simultaneously channeling water, oil, and other contaminants out from under the shoe, maximizing sole-to-floor contact.

The Role of Flexibility

An outsole must have a calculated balance between rigidity and flexibility. A sole that is too stiff can reduce your foot's natural feel for the ground, while one that is too flimsy may compromise support and stability.

Proper flexibility allows the tread to adapt to uneven terrain and helps the shoe's grooves conform to the foot's natural motion, enhancing both comfort and reliable traction.

Matching the Shoe to the Hazard

The most common mistake is assuming all slip-resistant shoes are created equal. The right shoe is one that is specifically designed for the hazards you face daily.

For Wet or Water-Covered Surfaces

In environments like kitchens, healthcare facilities, or food processing plants, the primary hazard is water.

Shoes with soft rubber outsoles and deep grooves are ideal. The grooves act like tire treads, effectively dispersing water to maintain direct contact with the floor.

For Oily or Greasy Environments

Oily and greasy surfaces, common in automotive shops and industrial kitchens, are notoriously difficult. Oil degrades certain materials and makes surfaces exceptionally slick.

You need an outsole specifically rated for oil resistance. These use rubber compounds that will not break down when exposed to petrochemicals and feature tread patterns designed to push viscous liquids away.

For Uneven or Varied Terrain

Construction sites or outdoor jobs involve unpredictable surfaces, from loose gravel to mud and slick concrete.

Here, multidirectional and aggressive lugs are critical. This design provides reliable grip from any angle, while a slightly more rigid sole can offer better protection and stability on rough ground.

Understanding the Trade-offs

Choosing the right shoe involves balancing competing priorities. Understanding these trade-offs is key to avoiding common pitfalls.

Aggressive Treads vs. Smooth Surfaces

While deep lugs are excellent for liquids or loose debris, they can create a "walking on stilts" effect on very smooth, dry surfaces. Some specialized designs feature reduced trip-hazard zones—smoother areas on the outsole—to allow for easier movement between different floor types.

Durability vs. Maximum Grip

Often, the softest and "grippiest" rubber compounds wear down the fastest. A harder, more durable rubber may last longer but offer slightly less traction. Your choice depends on the frequency of use and the severity of the slip hazard.

Slip Resistance vs. Other Safety Needs

Slip resistance is just one aspect of a safety shoe. Your job may also require a steel toe, electrical hazard (EH) protection, or puncture resistance. These features can affect the shoe's weight, flexibility, and overall design, so you must consider all requirements together.

Making the Right Choice for Your Environment

Your specific job role and workplace are the ultimate guide. Use these points to narrow down your selection.

- If your primary focus is wet and oily kitchen or factory floors: Prioritize shoes with certified oil-resistant rubber outsoles and tread patterns designed to channel away liquids.

- If your primary focus is construction or outdoor work: Look for deep, aggressive, multidirectional lugs for varied terrain and a durable material that resists abrasion.

- If your primary focus is indoor movement on primarily wet floors (e.g., healthcare, janitorial): A flexible shoe with a soft rubber sole and effective water-channeling grooves will provide the best balance of safety and comfort.

Ultimately, selecting the right work shoe is a critical investment in your personal safety, empowering you to perform your job with confidence and stability.

Summary Table:

| Factor | Key Consideration | Why It Matters |

|---|---|---|

| Outsole Material | Rubber, Gum Rubber, TPR | Provides high friction and resistance to oil, water, and chemicals. |

| Tread Pattern | Deep, multi-directional lugs | Channels liquids away and bites into surfaces to prevent slips. |

| Flexibility | Balanced rigidity and flex | Ensures comfort and stable contact with the ground. |

| Hazard Matching | Wet vs. Oily vs. Uneven Terrain | The right combination is critical for specific work environments. |

Need Slip-Resistant Work Shoes for Your Team? Partner with 3515, Your Trusted Manufacturer.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of slip-resistant shoes and boots, engineered with the right materials and tread designs to protect your workforce in any environment—from wet kitchens to oily industrial floors and rugged construction sites.

We combine durable materials, advanced tread patterns, and compliance with safety standards to deliver footwear that minimizes risk and maximizes productivity.

Let's discuss your specific needs and get a custom quote. Contact our experts today!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data