Alright, here's how I'm going to approach answering this durability question. I need to make sure I’m providing a comprehensive and useful response that addresses the user's need.

First, I need to get to the heart of the matter. They're asking about the "what," the durability of nano composite toe caps. But I need to go deeper. They're not just curious, they are trying to choose the right safety footwear. The key is to weigh the pros (lightweight) against the cons (durability, protection levels) and compare it with the other common option, steel. I need to give them a well-rounded and unbiased guide that helps them make a safe decision.

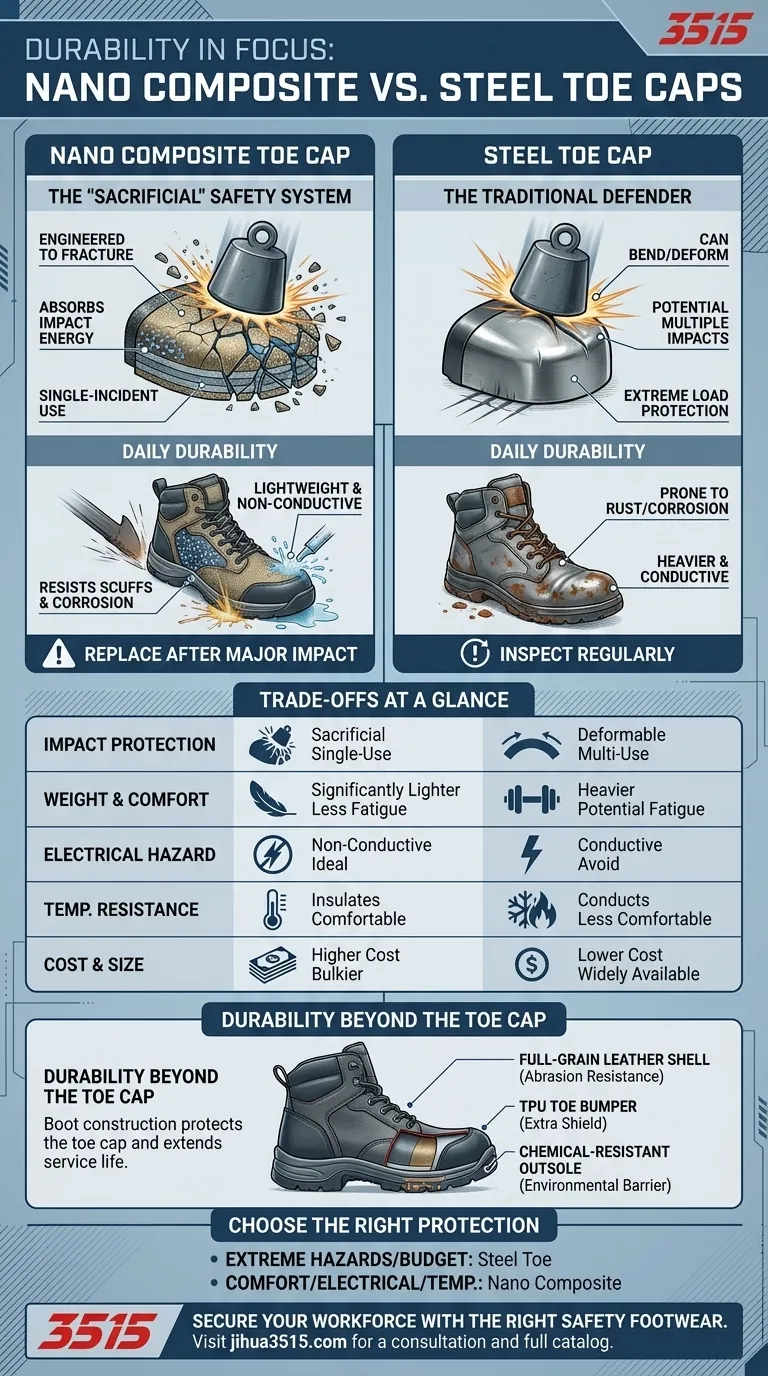

I’ve got the research, so let's break it down. References 1 and 2 highlight the core issue: nano composite can crack under heavy impacts. This makes them essentially "single-incident" footwear. Durability, in this context, has a critical limitation—the need for replacement after a serious impact. Reference 3 is great because it talks about the entire boot. A durable toe cap doesn’t do much good if the rest of the boot falls apart. Features like full-grain leather, abrasion resistance, and chemical resistance are important too. I can use this to show that the durability is not just about the toe cap itself.

Reference 4 is a goldmine for comparing nano composite to steel. It highlights the weight, cost, and conductivity trade-offs. It even brings up that both meet safety standards. I can use this to provide a clear comparison that lets the user see the whole picture. Reference 5 is even better because it adds a few caveats that make the whole picture a lot more nuanced: composite materials can be bulkier, cost more, and might not offer the same protection in "extreme" scenarios. This is a critical point that the user must know.

Now, to structure it. I’ll start by directly addressing the question: nano composite toe caps are excellent for everyday wear, but they are designed to fracture in a serious accident. They are a "one-time use" safety feature. The main takeaway will be that while they meet safety standards and are comfortable, their true durability is defined by their "sacrificial" nature—they protect you by breaking, which means they need to be replaced after a major impact.

I'll break the main body into parts. I'll explain how nano composites actually work, and their "fracture-on-impact" mechanism. This is their core safety feature and their main durability limit. After a big hit, even if it doesn't look bad, the structural integrity is gone, so a replacement is necessary. I'll also bring up their resistance to normal wear, chemicals, and temperature.

Then I’ll put it in context by saying that durability is about more than just the toe cap. I'll explain the role of the boot's construction. I’ll say that features like full-grain leather and abrasion-resistant materials protect the toe cap itself, and that TPU toe protectors are an added layer. I’ll mention the environmental resistance to chemicals.

The most important part will be comparing nano composite to steel based on the research. I'll highlight that steel is a good choice for extreme situations, while nano composite is great for reducing fatigue and working with electricity or extreme temperatures. I'll make sure to highlight the cost difference and broader availability of steel, too.

Finally, I’ll wrap up with actionable advice. I’ll create bullets based on different scenarios: maximum protection, all-day comfort, specific environmental hazards, and budget considerations. The goal is to ensure the user knows which choice is right for their particular needs. A good concluding statement is crucial, something like "Understanding these core principles ensures you choose footwear that protects you effectively for the specific demands of your work." This way, I can make sure the answer is comprehensive, accurate, and truly helpful to the user. At its core, the durability of a nano composite toe cap is defined by a critical trade-off. While they are exceptionally resilient to daily wear, scuffs, and lesser impacts, they are engineered to crack or shatter under a severe, direct blow. This is a safety feature, not a flaw; the cap sacrifices its own structure to absorb the energy and protect your foot, making the boot a single-use item in a serious accident.

The central takeaway is that nano composite toe caps are not "durable" in the traditional sense of withstanding repeated heavy abuse. Their durability lies in their reliable, one-time performance during a major impact, after which they must be replaced to ensure safety.

The Nature of Nano Composite Protection

To understand the durability of a nano composite toe, you must first understand how it is designed to function. It operates on a different principle than traditional steel.

How They Handle Impact

Unlike a steel toe, which can bend or deform under extreme pressure and potentially trap the foot, a nano composite toe is designed to dissipate energy by fracturing.

When a heavy object strikes the cap, the composite material absorbs the force and breaks apart. This sacrificial action prevents the toe box from collapsing inward.

The "Single-Incident" Principle

This fracture-based protection means the toe cap's integrity is compromised after one significant incident. Even if the damage is not visible, micro-cracks will have formed.

For this reason, boots with nano composite toes must be replaced immediately following any severe impact. Continuing to wear them provides a false sense of security.

Durability in Everyday Use

For daily wear and tear, nano composite caps are highly durable. They resist scratches, scuffs, and minor bumps without issue.

They are also non-reactive, making them resistant to chemicals and corrosion that could degrade other materials over time.

Durability is More Than Just the Toe Cap

The lifespan of your safety footwear depends on the entire boot's construction, which works to protect the toe cap itself from premature wear.

The Role of Boot Construction

High-quality materials like full-grain leather and other abrasion-resistant fabrics create a durable shell around the safety toe. This outer layer absorbs the brunt of daily friction and scuffs.

External Reinforcements

Many boots feature an external thermoplastic polyurethane (TPU) "toe bumper" or overlay. This added layer acts as a shield, significantly increasing the boot's resistance to abrasion and extending its service life.

Environmental Resistance

The overall durability is also enhanced by features like chemical and oil-resistant outsoles and materials. These prevent the boot's structure from breaking down in harsh environments, which maintains the integrity of the housing around the toe cap.

Understanding the Trade-offs: Composite vs. Steel

Choosing a nano composite toe involves weighing its unique properties against the long-standing benchmark of steel. Both meet established safety standards, but they serve different needs.

Protection in Extreme Scenarios

While both are rated for the same impact standards, their failure modes differ. Steel can bend, while composite shatters. In an extreme crushing event beyond the rating, some professionals prefer the known performance of steel.

Weight and Comfort

This is the primary advantage of nano composite. The material is significantly lighter than steel, which reduces foot fatigue over a long workday.

Environmental Factors

Nano composite toes do not conduct electricity, making them essential for electricians or those working near live currents. They also do not transfer heat or cold, offering superior comfort in extreme temperatures.

Cost and Physical Size

Composite caps are typically more expensive than steel. They also tend to be slightly thicker to achieve the same safety rating, which can result in a bulkier-looking toe box.

Making the Right Choice for Your Environment

Your decision should be based on a clear understanding of your daily tasks and potential hazards.

- If your primary focus is working with electrical hazards or in extreme temperatures: Nano composite is the superior and often necessary choice due to its non-conductive properties.

- If your primary focus is all-day comfort and reducing fatigue in a moderate-risk environment: The lightweight nature of nano composite offers a significant advantage.

- If your primary focus is protection against extreme crush forces on a tight budget: Steel toe boots are often more affordable and have a long-established track record in heavy industrial settings.

- If your primary focus is a balance of modern features and protection: A nano composite boot with external TPU reinforcement offers excellent comfort and enhanced daily durability.

Choosing the right safety toe is about matching the material's specific strengths to the realities of your work environment.

Summary Table:

| Factor | Nano Composite Toe Cap | Steel Toe Cap |

|---|---|---|

| Impact Protection | Sacrificial; fractures on severe impact (single-use) | Can bend/deform; may protect in multiple impacts |

| Weight & Comfort | Significantly lighter, reduces fatigue | Heavier, can cause fatigue over long shifts |

| Electrical Hazard | Non-conductive, ideal for electrical work | Conducts electricity, not suitable for live currents |

| Temperature Resistance | Does not transfer heat/cold, good for extreme temps | Conducts temperature, less comfortable in extremes |

| Cost & Availability | Typically higher cost, slightly bulkier design | Often more affordable, widely available |

| Durability (Daily Wear) | Resistant to scuffs, chemicals, and corrosion | Prone to rust and corrosion if not properly maintained |

Secure Your Workforce with the Right Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of footwear, including advanced nano composite and traditional steel toe options, designed to meet the specific durability and safety needs of your industry.

We help you equip your team with footwear that balances critical protection, all-day comfort, and long-term value. Let's discuss your requirements and ensure you have the right solution for your workforce's safety and productivity.

Contact us today for a consultation and to explore our full catalog of durable safety footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What are the different types of firefighter boots available? Choose the Right Boot for Your Mission

- What should safety shoes have? Essential Features for Ultimate Workplace Protection

- What type of safety boots are suitable for an oil construction worker? Essential Features for Hazardous Sites

- What are the two main organizations for safety footwear standards? Ensure OSHA Compliance with the Right Standard

- What are aluminum-toed shoes and how do they differ from steel-toed shoes? Choose the Right Safety Toe for Your Job

- What are the different types of fastening systems for motorcycle boots? Find Your Perfect Fit & Security

- Why might mobile workers prefer composite toe boots? Lighter, Safer, and More Comfortable for All-Day Wear

- What is the primary function of the structural support system in industrial Safety Shoes? Stability & Injury Prevention