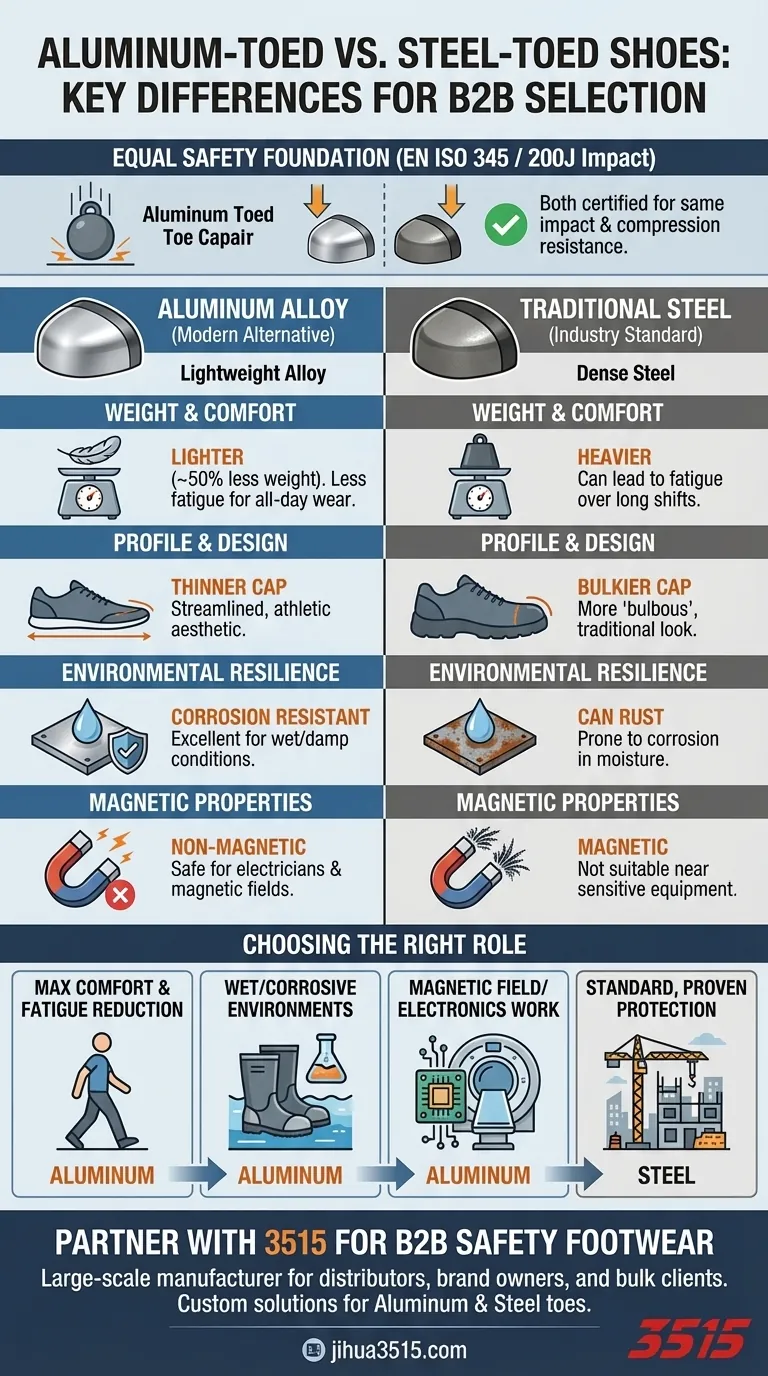

The fundamental difference is the material used for the protective toe cap, which directly impacts the shoe's weight, profile, and suitability for certain environments. Aluminum-toed shoes use a lightweight aluminum alloy for protection, whereas steel-toed shoes use steel. While both are engineered to meet the same rigorous safety standards for impact resistance, their material properties create distinct advantages for the wearer.

While both steel and aluminum toe caps provide the same certified level of impact protection, the choice between them is a critical decision based on weight, comfort, and specific workplace hazards like magnetic fields or corrosive elements.

The Foundation: Equal Safety, Different Materials

To make an informed decision, it's crucial to understand that the core safety function is equivalent. The divergence lies entirely in the characteristics of the metals used.

Adhering to the Same Safety Standards

Both aluminum and steel safety toes must meet identical industry standards for impact and compression resistance, such as the EN ISO 345 standard for "Safety shoes," which requires a 200-joule impact-resistant toe cap.

This means that from a pure protection standpoint against falling objects or crushing forces, a certified aluminum-toed shoe is just as safe as a certified steel-toed shoe.

The Material Distinction: Steel vs. Aluminum Alloy

The choice of metal is what creates the practical differences. Steel is a traditional, dense, and extremely strong material that has been the industry standard for decades.

Aluminum alloy is a modern alternative that offers a much higher strength-to-weight ratio, providing the required protection with significantly less mass.

Key Differentiators Explained

The material differences translate into four key factors that you will notice during a long workday.

Weight and Comfort

This is the most significant advantage of aluminum. An aluminum toe cap is approximately half the weight of a steel toe cap offering the same level of protection.

This reduction in weight leads to less fatigue over a long shift, making aluminum-toed footwear a more comfortable option for individuals who are on their feet all day.

Profile and Design

Because of its strength, an aluminum toe cap can be thinner than its steel counterpart while still meeting safety standards.

This allows for a less "bulbous" or bulky toe box, resulting in footwear that can have a more streamlined, athletic, or casual appearance.

Environmental Resilience

Aluminum is naturally resistant to corrosion. This makes aluminum-toed shoes an excellent choice for work in wet, damp, or corrosive environments where steel might be prone to rust over time.

Magnetic Properties

Aluminum is non-magnetic. This is a critical safety feature for electricians, engineers, or anyone working in environments with powerful magnets or machinery where magnetic interference is a concern.

Understanding the Trade-offs

Choosing the right safety toe involves balancing these characteristics against your specific needs and work environment. There is no single "best" option, only the most appropriate one for the task.

Bulk vs. Weight

The primary trade-off is straightforward. Steel provides proven, robust protection but comes with a significant weight penalty that can lead to fatigue.

Aluminum provides the same protection in a lighter, more comfortable package, which is often reflected in the footwear's overall design and feel.

Choosing for Job-Specific Hazards

Your daily tasks dictate the right choice. If you are simply on a construction site with impact hazards, both are perfectly suitable.

However, if your role involves passing through metal detectors frequently, working near strong magnetic fields, or being exposed to constant moisture, the specific properties of aluminum become a clear advantage.

Making the Right Choice for Your Role

Select your footwear by prioritizing the demands of your job.

- If your primary focus is reducing fatigue and maximizing all-day comfort: Aluminum is the superior choice due to its significantly lighter weight.

- If you work in wet, humid, or corrosive environments: Aluminum's natural corrosion resistance offers better long-term durability.

- If you work around powerful magnets or sensitive electronic equipment: Aluminum is the only suitable option as it is non-magnetic.

- If you require standard, proven protection without specific environmental concerns: Traditional steel-toed footwear is a perfectly effective and widely available solution.

Ultimately, understanding these material differences allows you to select the safety footwear that best supports your specific daily tasks and work environment.

Summary Table:

| Feature | Aluminum-Toed Shoes | Steel-Toed Shoes |

|---|---|---|

| Weight | Lighter (approx. 50% less) | Heavier |

| Toe Cap Profile | Thinner, more streamlined | Bulkier, traditional |

| Corrosion Resistance | Excellent | Can rust in wet environments |

| Magnetic Properties | Non-magnetic | Magnetic |

| Best For | All-day comfort, wet/chemical environments, electricians | Standard protection, high-impact environments |

Need High-Quality Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether your workforce requires the lightweight comfort of aluminum toes or the proven durability of steel toes, our production capabilities encompass all types of safety shoes and boots to meet your exact specifications and safety standards.

Let us equip your team with the right protection. Contact our experts today to discuss your needs and receive a customized solution.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?