Beyond simple durability, modern men's work shoes are engineered with a suite of specific safety technologies designed to mitigate workplace hazards. These core protections include reinforced safety toes (steel, composite, or aluminum), puncture-resistant midsoles, slip-resistant outsoles, and specialized safeguards against electrical currents.

The most critical aspect of work shoe safety is not any single feature, but the correct alignment of specific technologies to your unique workplace risks. Understanding whether you need impact protection, puncture resistance, or electrical insulation is the key to ensuring true on-the-job safety.

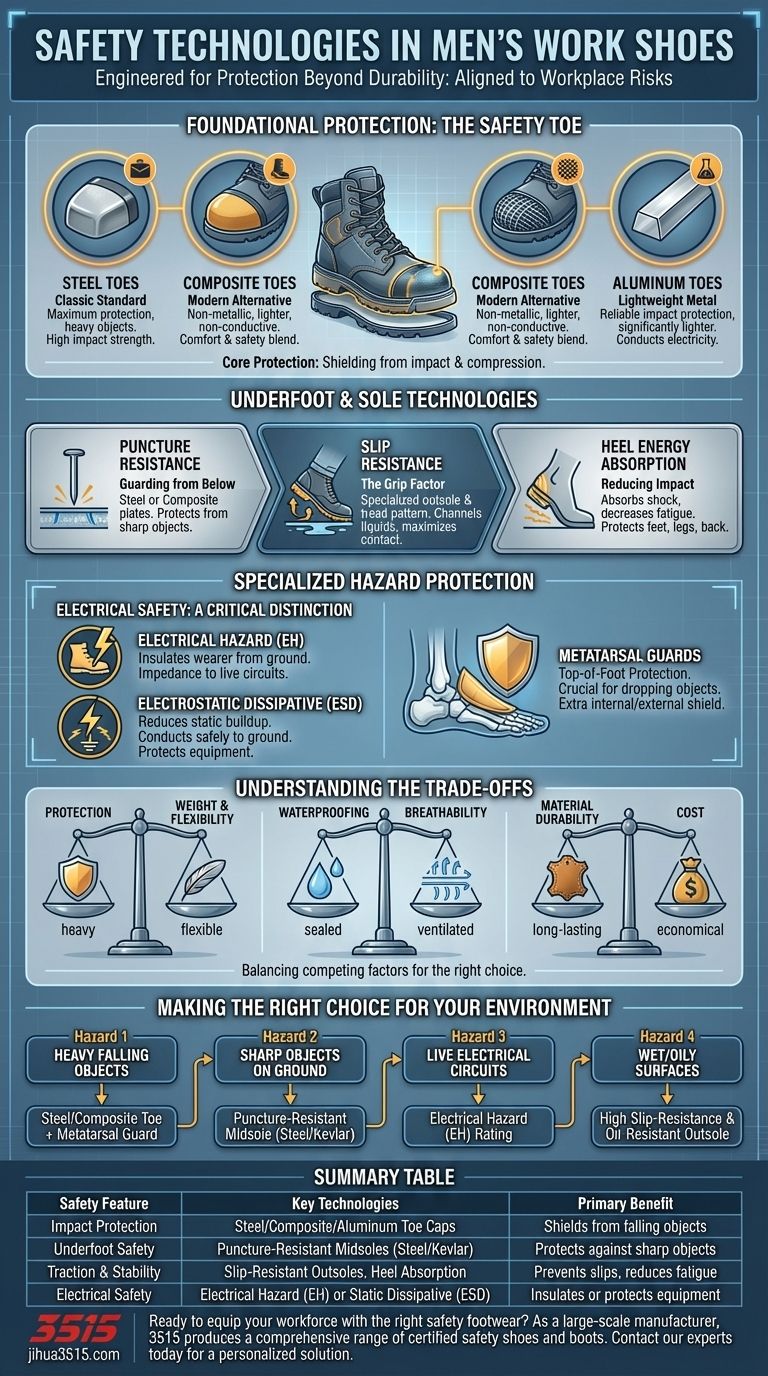

Foundational Protection: The Safety Toe

The most recognized safety feature is the protective toecap, which shields the foot from impact and compression. However, the material used for the cap has significant implications.

Steel Toes: The Classic Standard

Steel is the traditional material for safety toes due to its proven strength and ability to withstand high impact. It provides maximum protection against heavy falling or rolling objects.

Composite Toes: The Modern Alternative

Composite toes are made from non-metallic materials like Kevlar, carbon fiber, or plastic. They are lighter than steel, do not conduct electricity, and don't transfer cold in frigid environments, offering a blend of safety and comfort.

Aluminum Toes: The Lightweight Metal

Offering a middle ground, aluminum toes provide reliable impact protection but are significantly lighter than steel. Like steel, they conduct electricity and temperature.

Underfoot and Sole Technologies

The sole of a work shoe is a critical interface between you and your work surface, providing protection from multiple angles.

Puncture Resistance: Guarding from Below

To protect against sharp objects like nails or metal shards, many work shoes feature a puncture-resistant plate in the midsole. These can be steel plates for maximum rigidity or flexible composite fabric plates (like Kevlar) that allow for more natural foot movement.

Slip Resistance: The Grip Factor

A slip-resistant outsole is essential in environments with water, oil, or other liquids. This technology relies on both the outsole material (like rubber or polyurethane) and a specialized tread pattern designed to channel liquids away and maximize surface contact. Many are also rated as oil and fuel resistant.

Heel Energy Absorption: Reducing Impact

This feature is designed to reduce the impact on your feet, legs, and back when walking on hard surfaces. It absorbs shock at the heel, decreasing fatigue and long-term strain.

Specialized Hazard Protection

Beyond universal needs like impact and slip resistance, many jobs require protection from less common but highly dangerous risks.

Electrical Safety: A Critical Distinction

It is vital to understand the difference between ratings for electrical work. They are not interchangeable.

Electrical Hazard (EH) rated shoes are designed to insulate the wearer from the ground, impeding the flow of electricity. They protect against accidental contact with live electrical circuits.

Electrostatic Dissipative (ESD) and Antistatic shoes do the opposite. They are engineered to reduce the buildup of static electricity by conducting it safely to the ground. This protects sensitive electronic equipment from damage, not the wearer from a live current.

Metatarsal Guards: Top-of-Foot Protection

For jobs with a high risk of objects dropping directly onto the top of the foot, a metatarsal guard is crucial. This extra shield, either internal or external, covers the delicate metatarsal bones that a standard safety toe does not.

Understanding the Trade-offs

Choosing the right work shoe involves balancing competing factors. No single shoe is perfect for every situation.

Protection vs. Weight and Flexibility

Generally, the highest levels of protection (e.g., steel toes and midsoles) add weight and reduce flexibility. This can increase fatigue over a long workday. Composite materials often provide a lighter, more flexible alternative.

Waterproofing vs. Breathability

A fully waterproof boot is excellent for keeping feet dry from external moisture. However, this same barrier can trap sweat, leading to discomfort. Look for shoes with breathable waterproof membranes to balance these two needs.

Material Durability vs. Cost

Materials like full-grain leather offer exceptional durability and longevity but come at a higher price point. Synthetic materials may be lighter and less expensive but might not withstand the same level of abuse over time.

Making the Right Choice for Your Work Environment

Your specific job hazards must dictate your choice. Use this guide to select the technologies you truly need.

- If your primary focus is protection from heavy falling objects: Prioritize a shoe with a certified steel or composite safety toe and consider adding a metatarsal guard.

- If your primary focus is working around sharp objects on the ground: A puncture-resistant midsole, made of steel or a composite fabric like Kevlar, is non-negotiable.

- If your primary focus is working with live electrical circuits: You must select a boot with an Electrical Hazard (EH) rating to ensure proper insulation.

- If your primary focus is preventing slips on wet or oily surfaces: Scrutinize the outsole for a high slip-resistance rating and an oil-resistant material.

Choosing the right work shoe is an investment in your personal safety, empowering you to perform your job with confidence and protection.

Summary Table:

| Safety Feature | Key Technologies | Primary Benefit |

|---|---|---|

| Impact Protection | Steel, Composite, or Aluminum Toe Caps | Shields feet from heavy falling objects |

| Underfoot Safety | Puncture-Resistant Midsoles (Steel/Kevlar) | Protects against sharp objects like nails |

| Traction & Stability | Slip-Resistant Outsoles, Heel Absorption | Prevents slips on wet/oily surfaces, reduces fatigue |

| Electrical Safety | Electrical Hazard (EH) or Static Dissipative (ESD) | Insulates from live circuits or protects sensitive equipment |

Ready to equip your workforce with the right safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. We can help you select or custom-design footwear with the precise safety technologies—from composite safety toes to EH-rated soles—that match your specific workplace hazards.

Contact our experts today to discuss your requirements and receive a personalized solution that prioritizes safety and comfort.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- How do design and material selection contribute to non-slip footwear effectiveness? The Key to Superior Slip Resistance

- What is the purpose of standardized ankle weight blocks? Enhancing Accuracy in Footwear Sensory Friction Evaluations

- What role does slip resistance play in firefighting boots? Ensuring Stability and Safety in Hazardous Conditions

- What are the benefits of using high-grip anti-slip work shoes for MBR tank maintenance? Ensure worker safety today!

- How does a whole-shoe portable bio-simulated mechanical slip tester provide superior performance characterization?

- What features make slip-on shoes practical for retail workers or flight attendants? Unlock All-Day Comfort & Convenience

- What is the role of sturdy winter footwear and anti-slip accessories for those with weakened motor control? Boost Safety

- Why is high flexibility and lateral support important in specialized footwear for mechanical assembly and tuning?