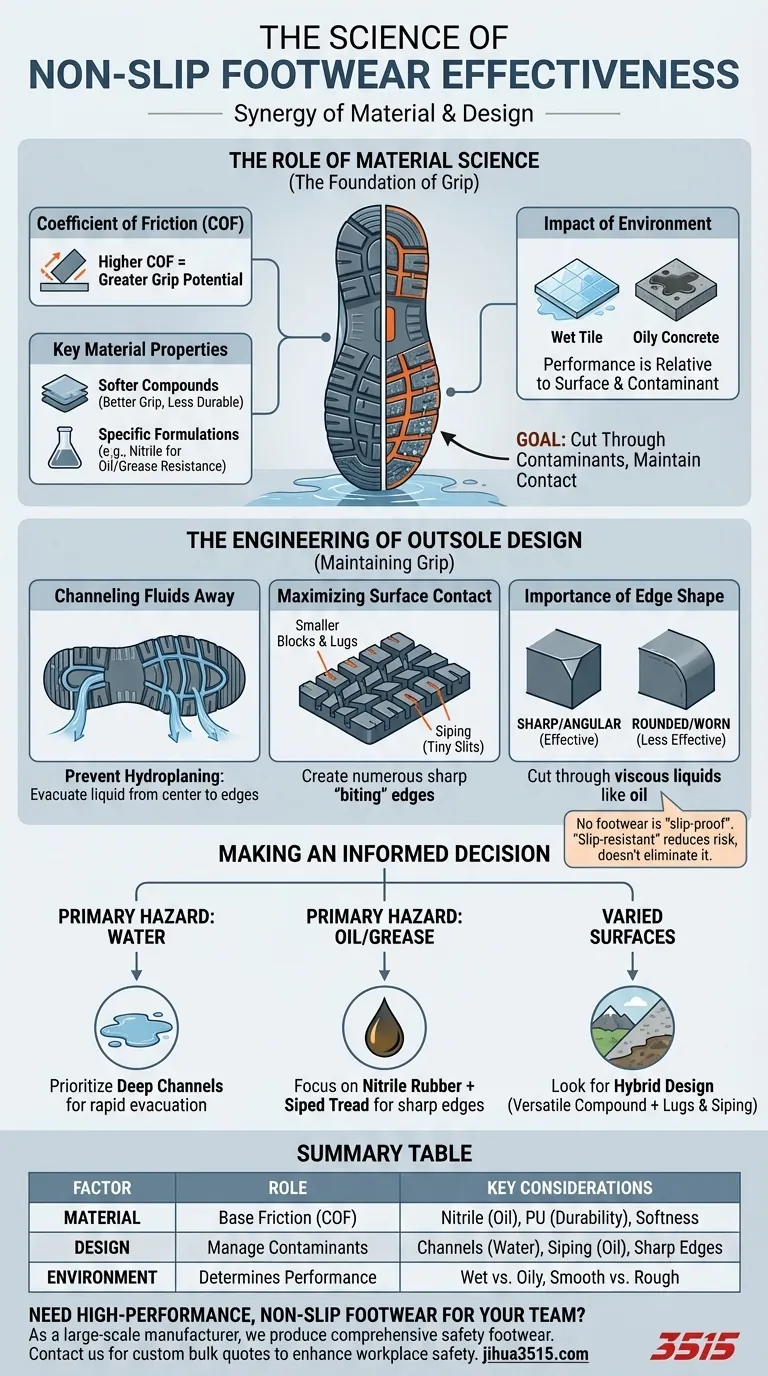

Ultimately, the effectiveness of non-slip footwear is not determined by a single feature, but by the synergistic relationship between its material composition and its outsole design. A high-friction material provides the potential for grip, while an intelligent tread design ensures that potential is realized by effectively managing contaminants like water or oil on the walking surface.

The central principle of slip resistance is not just about gripping the floor, but about the shoe's ability to cut through liquid contaminants, clear them away from the contact patch, and maintain direct, solid contact between the sole and the surface.

The Role of Material Science

The material of the outsole is the foundation of grip. It determines the inherent friction between the shoe and the walking surface, a property measured as the coefficient of friction (COF). A higher COF indicates greater resistance to sliding.

Key Material Properties

The ideal material possesses a high COF without sacrificing durability. Softer compounds generally offer more grip, especially on smooth, dry surfaces, as they can conform better to microscopic surface irregularities.

Common high-performance materials include specific formulations of rubber and polyurethane (PU). Nitrile rubber, for instance, is often favored in kitchen or industrial settings for its excellent resistance to oil and grease, which can degrade other materials and reduce their effectiveness.

The Impact of the Environment

A material's performance is not absolute; it is relative to the surface and the contaminant. A compound that performs exceptionally on a wet tile floor might be less effective on an oily concrete surface. This is why material selection must be matched to the specific hazards of the environment.

The Engineering of Outsole Design

If the material provides the potential for grip, the design of the outsole is what allows that grip to be maintained in real-world, contaminated conditions. The primary job of the tread pattern is to manage fluids.

Channeling Fluids Away

The most important feature of a non-slip tread is its ability to move liquid away from the area directly underfoot. This prevents hydroplaning, a phenomenon where a layer of liquid separates the sole from the floor, causing a near-total loss of friction.

Effective designs use interconnected channels that start from the center of the sole and direct fluid outwards to the edges, clearing the contact patch.

Maximizing Surface Contact

While it may seem counterintuitive, reducing the total surface area in favor of a pattern of smaller, independent tread blocks (or lugs) can increase slip resistance.

These smaller blocks create numerous sharp edges that can "bite" into the surface. Furthermore, many high-performance outsoles feature siping—tiny, razor-thin slits cut into the tread blocks. These sipes open up as the foot flexes, increasing the number of sharp edges to cut through fluid film.

The Importance of Edge Shape

The geometry of the tread blocks matters. Sharp, angular edges are far more effective at cutting through viscous liquids like oil than rounded, worn-out edges. A new, well-defined tread will always outperform a worn-down one.

Understanding the Trade-offs

Choosing slip-resistant footwear involves balancing competing factors. There is no single "best" shoe, only the best shoe for a specific application and environment.

Grip vs. Durability

There is often a direct trade-off between the softness of a material (which enhances grip) and its hardness (which increases durability). The grippiest, softest rubber compounds may wear down quickly under heavy use, reducing the effectiveness of the tread pattern.

Contaminant Specificity

A tread pattern optimized for water, with wide and deep channels, may not be the most effective for thicker, more viscous fluids like grease. The material's chemical resistance to the specific contaminant is also a critical consideration.

The "Slip-Resistant" Limitation

No footwear is "slip-proof." The term is slip-resistant, which acknowledges that it reduces the risk of slips but cannot eliminate it entirely. Factors like floor condition, wear on the sole, and the volume of the contaminant all play a significant role.

Making an Informed Decision

To select the most effective footwear, you must match the shoe's technology to the specific environmental hazards you face.

- If your primary hazard is water: Prioritize a tread design with deep, circular, or intersecting channels that can evacuate fluid quickly and efficiently from the center of the sole.

- If your primary hazard is oil or grease: Focus on the material composition first, selecting a compound like nitrile rubber that resists degradation, paired with a siped tread pattern that creates many biting edges.

- If you work on varied surfaces: Look for a hybrid design with a versatile rubber compound and a tread pattern that combines both larger lugs for stability and fine siping for wet traction.

Ultimately, understanding that materials create friction while design maintains it is the key to making an empowered and effective safety choice.

Summary Table:

| Factor | Role in Slip Resistance | Key Considerations |

|---|---|---|

| Material | Provides the base friction (Coefficient of Friction). | - Nitrile rubber for oil/grease resistance - Polyurethane (PU) for durability - Softer compounds for better grip |

| Outsole Design | Manages contaminants to maintain contact with the floor. | - Channels to evacuate water - Siping for sharp edges to cut through oil - Sharp, angular tread block edges |

| Environment | Determines the required performance. | - Wet floors vs. oily surfaces - Smooth tile vs. rough concrete - Chemical resistance needs |

Need high-performance, non-slip footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of slip-resistant shoes and boots, engineered with the precise material and design principles outlined above to protect your workforce in any environment.

Contact us today to discuss your specific needs and get a custom quote. We'll help you select the perfect footwear solution to enhance workplace safety and reduce slip-related incidents.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What do heavy duty boots do? Protect Your Feet in Demanding Work Environments

- Do snake bite boots work? Your Ultimate Guide to Effective Snake Bite Protection

- What are OSHA approved shoes? Understanding the Correct Standards for Workplace Safety

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job