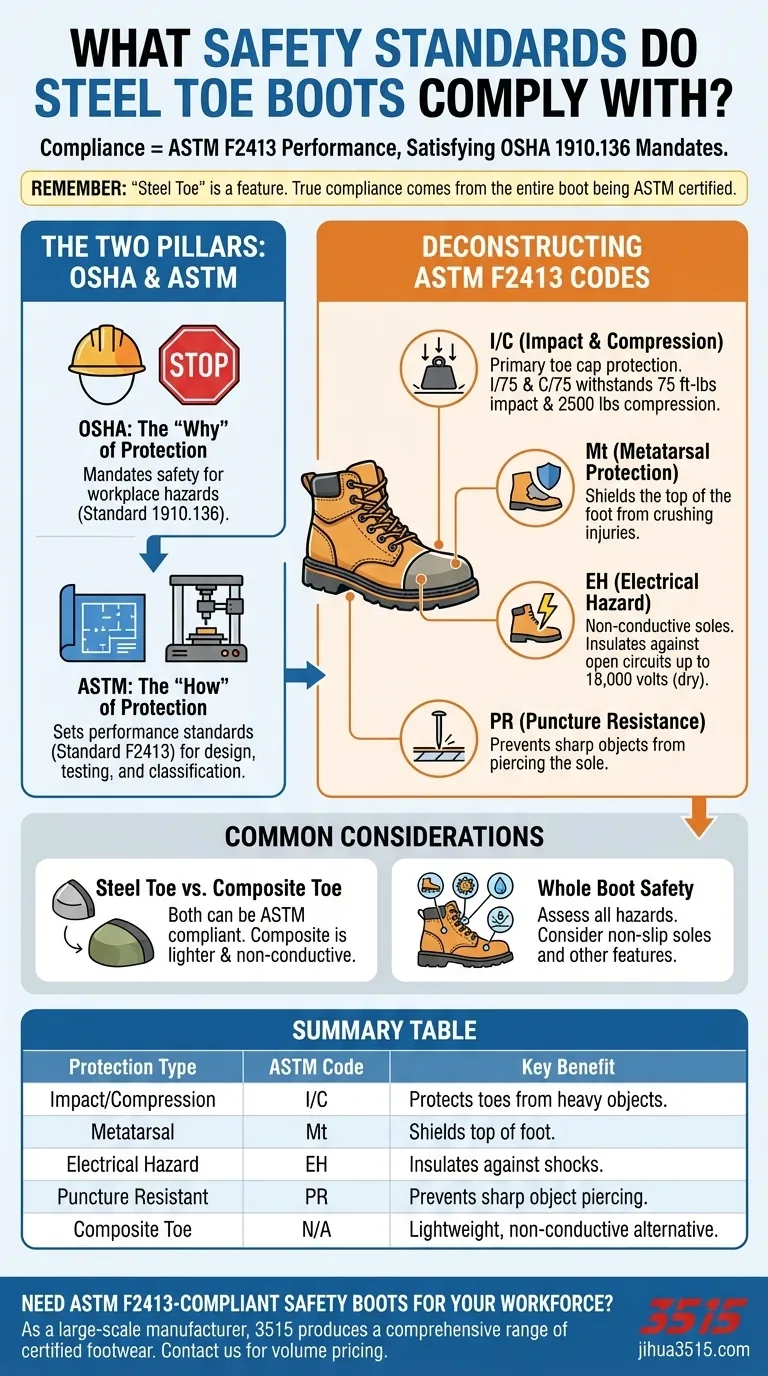

To be compliant, steel toe boots must meet the performance standards set by the American Society for Testing and Materials (ASTM), specifically the ASTM F2413 standard. This certification is what satisfies the legal requirements for protective footwear mandated by the Occupational Safety and Health Administration (OSHA) under standard 1910.136.

The critical point to understand is that "steel toe" is a feature, not a standard. True safety compliance comes from the entire boot being certified against specific workplace hazards—like impact, compression, and electrical shock—as defined by ASTM standards.

The Two Pillars of Footwear Safety: OSHA and ASTM

To grasp footwear safety, you must understand the relationship between two key organizations. OSHA defines when you need protection, and ASTM defines how that protection must perform.

OSHA's Role: The "Why" of Protection

The Occupational Safety and Health Administration (OSHA) is a government agency that sets and enforces workplace safety regulations.

OSHA Standard 1910.136 requires employers to ensure their employees wear protective footwear when working in areas with a danger of foot injuries.

This includes risks from falling or rolling objects, items that could pierce the sole, and electrical hazards.

ASTM's Role: The "How" of Protection

The American Society for Testing and Materials (ASTM) is an international organization that develops and publishes technical standards.

ASTM F2413 is the "Standard Specification for Performance Requirements for Protective (Safety) Toe Cap Footwear." A boot must be tested against these criteria to be considered compliant.

This standard outlines the minimum requirements for design, performance, testing, and classification. It ensures the boot provides real, measurable protection.

Deconstructing the ASTM F2413 Standard

An ASTM-compliant boot is more than just a steel cap. The standard covers a range of protective features, and certified boots will have codes indicating which protections they offer.

Impact and Compression Resistance (I/C)

This is the primary function of the safety toe cap. The label on the boot will specify its rating for both Impact (I) and Compression (C) resistance.

The highest rating is I/75 and C/75, meaning the toe cap can withstand 75 foot-pounds of impact and 2,500 pounds of compression.

Metatarsal Protection (Mt)

Some boots offer additional protection for the metatarsal bones, which are the long bones on the top of your foot.

If a boot meets this standard, it will be marked with Mt. This is crucial in environments with a high risk of objects dropping directly onto the foot.

Electrical Hazard Protection (EH)

This type of boot is designed with non-conductive, shock-resistant soles and heels.

Boots rated for EH can protect the wearer from open circuits of up to 18,000 volts under dry conditions. This protection is negated if the boot becomes wet or if conductive materials are embedded in the sole.

Puncture Resistance (PR)

For workplaces with sharp objects like nails, screws, or scrap metal, puncture-resistant boots are essential.

These boots have a protective plate built into the midsole to prevent objects from piercing the sole of the foot. Compliant boots are marked with PR.

Common Pitfalls and Considerations

Choosing the right boot isn't just about finding an ASTM label. The specific environment and tasks dictate which features are truly necessary.

Steel Toe vs. Composite Toe

OSHA and ASTM do not mandate that a safety toe must be made of steel. Composite materials (like Kevlar, carbon fiber, or plastic) can also meet the ASTM F2413 standard.

As long as the boot carries the proper ASTM rating, either material is compliant. Composite toes are often lighter and do not conduct cold or electricity, making them better for certain environments.

It's About the Whole Boot

The toe cap is only one part of the safety system. A non-slip sole is critical for preventing falls, and water resistance can be vital for both comfort and electrical safety.

Always assess the full range of hazards in your environment, not just the risk of falling objects.

Making the Right Choice for Your Goal

Look for the ASTM F2413 label inside your boot to identify its specific protections.

- If your primary focus is protection from falling or heavy rolling objects: Ensure the boot is rated I/75 and C/75 for maximum impact and compression resistance.

- If your primary focus is working around live electrical circuits: You must select a boot with an Electrical Hazard (EH) rating.

- If your primary focus is construction, demolition, or scrap yards: A Puncture Resistant (PR) sole is non-negotiable to protect against sharp objects from below.

- If your primary focus is passing through metal detectors or working in extreme cold: Consider an ASTM-compliant composite toe boot to avoid conductivity issues.

Ultimately, understanding the specific ASTM codes on the boot's label is the only way to ensure you have the right protection for the task at hand.

Summary Table:

| Protection Type | ASTM Code | Key Benefit |

|---|---|---|

| Impact/Compression | I/C | Protects toes from heavy falling objects (up to 75 ft-lbs impact, 2,500 lbs compression) |

| Metatarsal | Mt | Shields the top of the foot from crushing injuries |

| Electrical Hazard | EH | Insulates against electrical shocks (up to 18,000 volts in dry conditions) |

| Puncture Resistant | PR | Prevents sharp objects from piercing the sole |

| Composite Toe | N/A | Lightweight, non-conductive alternative to steel; meets ASTM F2413 |

Need ASTM F2413-compliant safety boots for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of OSHA-compliant boots—including steel toe, composite toe, EH-rated, and puncture-resistant models—ensuring your team has the right protection for any hazard.

Contact us today for volume pricing and custom solutions tailored to your safety requirements.

Visual Guide

Related Products

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- Do steel toe boots lack style options? Discover Modern, Stylish Safety Footwear

- What are the primary protective functions of safety shoes with steel toes in the automotive repair industry?

- What are the main differences between composite toe and steel toe shoes? Choose the Right Safety Shoe

- What are the key benefits of steel toe boots? Unmatched Protection & Durability

- What are the advantages of wearing steel toe shoes? Maximum Protection for Your Workforce

- Is it true that steel toe boots make your toes colder? The Truth About Cold-Weather Work Boots

- Is there a downside to steel toe boots? Weighing Protection Against Daily Comfort

- Is the myth about steel-toe boots being dangerous true? Debunking the 'Guillotine Effect' Myth