In short, puncture resistance is a critical safety layer in fire boots that protects the sole of the foot from penetration by sharp objects. During firefighting and rescue operations, environments are often unstable and filled with unseen hazards like nails, broken glass, and sharp metal, making this feature a non-negotiable element of personal protective equipment (PPE).

The core purpose of puncture resistance is not merely to prevent minor cuts; it is to safeguard a firefighter against debilitating foot injuries that can occur in the chaotic and unpredictable environments of an emergency scene.

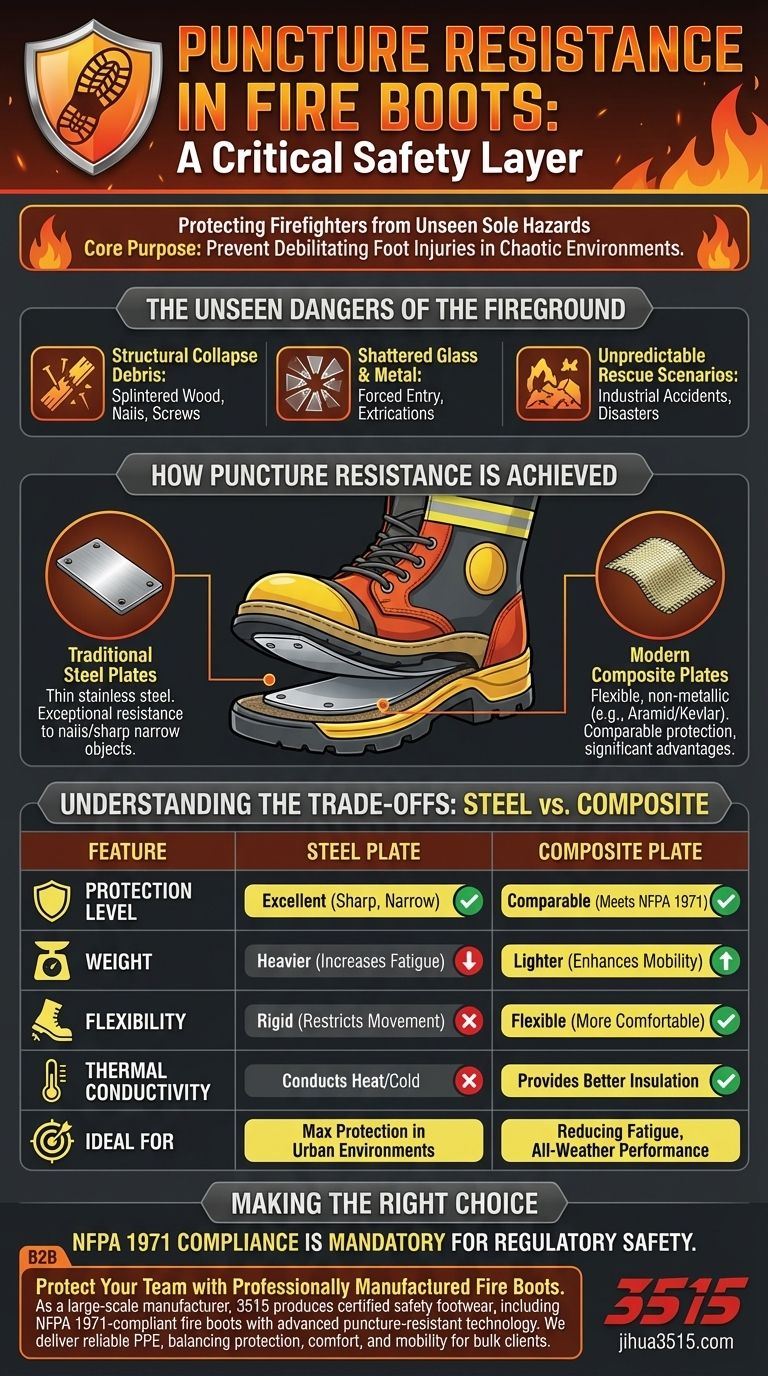

The Unseen Dangers of the Fireground

The environment a firefighter enters is rarely stable or predictable. After a fire or during a rescue, the ground is littered with hazards that are often obscured by smoke, debris, or water.

Debris from Structural Collapse

During overhaul operations or in a collapsed structure, firefighters constantly walk over splintered wood, exposed nails, and screws. A single misplaced step can result in a deep puncture wound.

Shattered Glass and Metal

Forced entry, broken windows, and torn metal from vehicle extrications create a minefield of sharp edges. The sole of the boot is the primary point of contact with these immediate threats.

Unpredictable Rescue Scenarios

From industrial accidents to natural disasters, rescue sites contain countless sharp objects. Puncture resistance provides a constant, reliable defense when the terrain is unknown.

How Puncture Resistance is Achieved

This protection is integrated directly into the boot's sole assembly. The technology has evolved from traditional materials to more advanced composites, each with distinct characteristics.

Traditional Steel Plates

For decades, a thin plate of stainless steel embedded in the midsole was the industry standard. It offers exceptional resistance to penetration from sharp, narrow objects like nails.

Modern Composite Plates

Newer boots often use flexible, non-metallic plates made from materials like Aramid fibers (e.g., Kevlar). These woven fabric plates provide comparable protection while offering significant advantages in other areas.

Understanding the Trade-offs

Choosing the right boot involves balancing protection with performance and comfort. The material used for the puncture-resistant plate is a key factor in this equation.

Weight and Fatigue

Steel plates add noticeable weight to a boot, which can increase fatigue over the course of a long incident. Composite plates are significantly lighter, enhancing firefighter mobility and reducing strain.

Flexibility and Comfort

A rigid steel plate can make the sole of the boot stiff, restricting natural foot movement. Flexible composite plates allow for a more comfortable and ergonomic boot, which is critical when navigating uneven terrain.

Thermal Conductivity

Steel is an excellent conductor of temperature. In extreme cold, it can draw heat away from the foot, and in high-heat situations, it can potentially transfer that heat inward. Composite materials do not have this issue and provide better thermal insulation.

Making the Right Choice for Your Department

Selecting a boot is a decision that directly impacts safety and operational effectiveness. Your choice should align with your primary operational needs while always meeting established safety standards.

- If your primary focus is proven, maximum protection in urban environments: A boot with a steel plate provides time-tested defense against common construction hazards like nails.

- If your primary focus is reducing fatigue, increasing flexibility, and all-weather performance: Boots featuring modern composite plates are the superior choice for overall comfort and mobility.

- If your primary focus is regulatory compliance (the most critical factor): Ensure any boot you consider is certified to the latest NFPA 1971 standard, which mandates a specific level of puncture resistance regardless of material.

Ultimately, choosing a boot with certified puncture resistance is a fundamental step in ensuring your own safety on the fireground.

Summary Table:

| Feature | Steel Plate | Composite Plate |

|---|---|---|

| Protection Level | Excellent against sharp, narrow objects | Comparable to steel, meets NFPA 1971 |

| Weight | Heavier, can increase fatigue | Lighter, enhances mobility |

| Flexibility | Rigid, restricts foot movement | Flexible, more comfortable |

| Thermal Conductivity | Conducts heat/cold | Provides better insulation |

| Ideal For | Maximum protection in urban environments | Reducing fatigue, all-weather performance |

Protect Your Team with Professionally Manufactured Fire Boots

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear, including NFPA 1971-compliant fire boots with advanced puncture-resistant technology. We work directly with distributors, brand owners, and bulk clients to deliver reliable PPE that balances critical protection with firefighter comfort and mobility.

Contact our expert team today to discuss your department's specific needs and request a quote.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- When are steel-toe boots required or recommended? Essential Guide to Workplace Foot Safety

- What are the different types of materials used in the toe portion of safety toe work boots? A Guide to Steel, Alloy & Composite

- Which industries commonly use steel toe boots? Essential Foot Protection for High-Risk Jobs

- What are the main types of safety-toe boots? Choose the Right Protection for Your Job

- What factors should be considered when choosing between steel and composite toe caps? Ensure Maximum Safety and Comfort