In slip-resistant shoes, the outsole is the most critical component for safety. It is solely responsible for generating the necessary grip and friction on hazardous surfaces. Through a combination of specialized materials and engineered tread patterns, the outsole actively works to prevent falls on surfaces contaminated with water, oil, or food.

The effectiveness of a slip-resistant shoe is not about simple "grip," but a carefully engineered system within the outsole. Its soft rubber compound maximizes surface contact, while its specific tread pattern channels dangerous liquids away, ensuring a stable connection between the shoe and the floor.

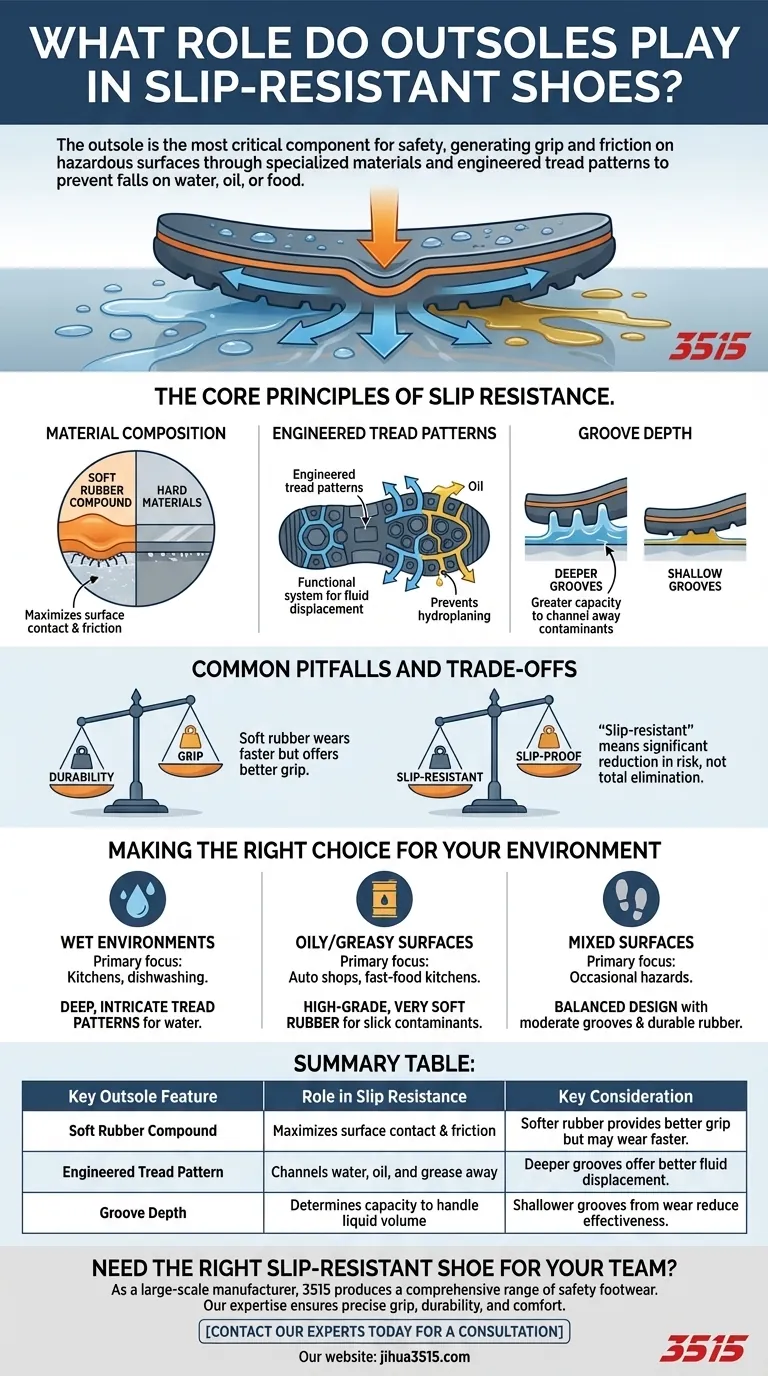

The Core Principles of Slip Resistance

To understand how an outsole prevents a fall, you must look at its two primary design features: the material it's made from and the physical shape of its tread.

The Role of Material Composition

The vast majority of slip-resistant outsoles are made from a soft rubber compound.

Unlike harder materials, soft rubber can better conform to the microscopic imperfections of a floor surface. This increases the total surface area in contact with the ground, which in turn maximizes friction. This quality is especially critical for maintaining grip on greasy or oily floors.

The Engineering of Tread Patterns

The pattern on the bottom of the shoe is not for aesthetics; it is a functional system for fluid displacement.

Think of it like the treads on a car tire in the rain. Micro-patterns, often circular or hexagonal, create small channels that push liquids out from under the foot. This prevents a layer of water or oil from forming between the shoe and the floor, a phenomenon known as hydroplaning, which is a primary cause of slips.

The Importance of Groove Depth

The channels created by the tread pattern must have sufficient depth to be effective.

Deeper grooves provide a greater capacity to channel away contaminants. This ensures that even with a significant amount of liquid on the floor, the outsole can maintain direct contact with the solid surface, preserving a high level of friction and stability.

Common Pitfalls and Trade-offs

While essential for safety, the design of slip-resistant outsoles involves inherent compromises that are important to understand.

Durability vs. Grip

The soft rubber that provides excellent grip is also, by its nature, less durable than harder compounds.

This means that shoes with the highest level of slip resistance may wear down more quickly, especially if used frequently on rough surfaces like asphalt or concrete. The treads will become shallower over time, reducing their ability to channel fluids and diminishing their effectiveness.

"Resistant" Does Not Mean "Proof"

It is critical to remember that no shoe is completely slip-proof.

The term "slip-resistant" indicates a significant reduction in risk, not its complete elimination. The shoe's effectiveness can be compromised by the specific type of contaminant, the volume of the spill, and the condition of both the flooring and the outsole itself. This technology provides confidence and stability, but caution remains necessary.

Making the Right Choice for Your Environment

Choosing the correct slip-resistant shoe depends entirely on the specific hazards you face in your environment.

- If your primary focus is working in wet environments (e.g., kitchens, dishwashing areas): Look for shoes with deep, intricate tread patterns specifically designed to channel away large amounts of water.

- If your primary focus is working around oily or greasy surfaces (e.g., auto shops, fast-food kitchens): Prioritize outsoles made from a high-grade, very soft rubber compound for maximum grip on slick contaminants.

- If your primary focus is walking on mixed surfaces with occasional hazards: A balanced design with moderate groove depth and a durable rubber compound will provide the most versatile and long-lasting protection.

Ultimately, understanding the science of the outsole empowers you to choose footwear that provides genuine safety and stability for your specific needs.

Summary Table:

| Key Outsole Feature | Role in Slip Resistance | Key Consideration |

|---|---|---|

| Soft Rubber Compound | Maximizes surface contact & friction on slick surfaces. | Softer rubber provides better grip but may wear faster. |

| Engineered Tread Pattern | Channels water, oil, and grease away from the sole. | Deeper grooves offer better fluid displacement. |

| Groove Depth | Determines capacity to handle liquid volume. | Shallower grooves from wear reduce effectiveness over time. |

Need the right slip-resistant shoe for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our expertise in outsole engineering ensures your workforce gets the precise combination of grip, durability, and comfort for their specific environment—from kitchens to factories.

Contact our experts today for a consultation on your safety footwear needs.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

People Also Ask

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals