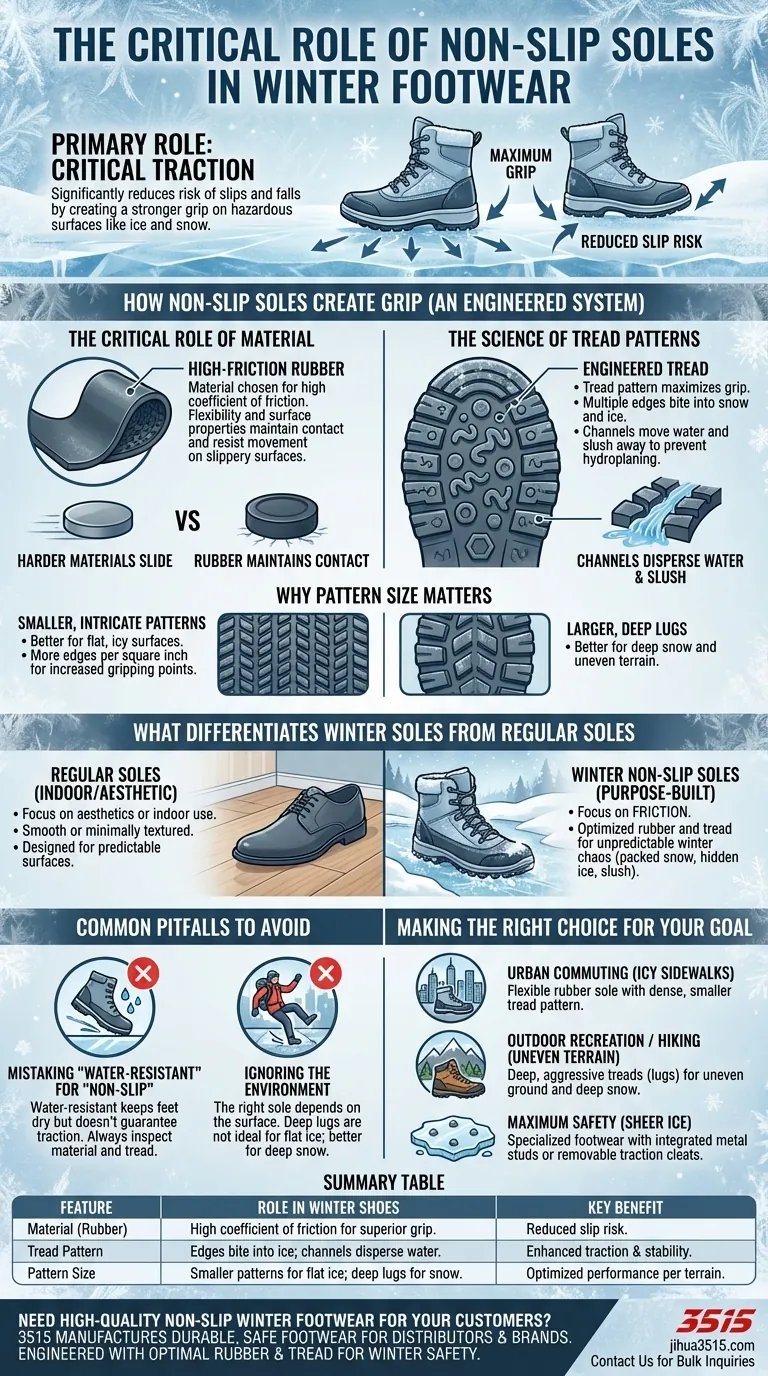

In winter footwear, the primary role of a non-slip sole is to provide critical traction on hazardous surfaces like ice and snow. This design significantly reduces the risk of slips and falls by creating a stronger grip than a standard shoe sole can offer.

The effectiveness of a winter shoe's non-slip sole is determined by a strategic combination of two factors: a high-friction material, typically rubber, and an intricate tread pattern designed to grip slippery, uneven ground.

How Non-Slip Soles Create Grip

Understanding the mechanics of a non-slip sole reveals that it's an engineered system, not just a simple piece of rubber. Both the material and its design are crucial for performance.

The Critical Role of Material

The vast majority of non-slip soles are made from rubber. This material is chosen for its naturally high coefficient of friction, which allows it to effectively grip surfaces.

Unlike harder, smoother materials that can easily slide over ice, rubber has the flexibility and surface properties to maintain contact and resist movement.

The Science of Tread Patterns

The pattern on the bottom of the sole, known as the tread, is engineered to maximize grip. These patterns are not merely for decoration.

Treads composed of squiggles, circles, or hexagonal shapes create multiple edges that bite into snow and ice. They also create channels that help move water and slush away from the point of contact, preventing a layer of liquid from causing you to hydroplane.

Why Pattern Size Matters

Generally, a tread with smaller, more intricate patterns provides better slip resistance on flat, icy surfaces.

These smaller patterns create more edges per square inch, increasing the number of points gripping the ground at any given moment.

What Differentiates Winter Soles from Regular Soles

While many shoes have some tread, non-slip winter soles are fundamentally different in their design philosophy and intended function.

A Focus on Friction

Regular shoes, especially dress shoes or fashion sneakers, may have smooth or minimally textured soles designed for aesthetics or indoor use.

Non-slip shoes, by contrast, are purpose-built for friction. Every element of the sole, from the softness of the rubber to the depth of the tread, is optimized to prevent sliding on wet or icy floors.

Designed for Unpredictable Surfaces

A standard shoe is designed for predictable surfaces like pavement or indoor flooring.

A winter non-slip sole is designed for the chaos of winter ground: packed snow, hidden ice, and slush. The durable, anti-skid construction provides a more stable base in these challenging conditions.

Common Pitfalls to Avoid

Choosing the right shoe involves understanding the balance between different features. A sole that excels in one area may compromise in another.

Mistaking "Water-Resistant" for "Non-Slip"

Many winter boots are labeled water-resistant to keep your feet dry. This is a critical feature, but it does not automatically guarantee high performance on ice.

Always inspect the sole's material and tread pattern directly. A boot can repel water perfectly but still have a sole that offers poor traction.

Ignoring the Environment

The ideal non-slip sole for a cleared but icy city sidewalk is different from one needed for a snowy hiking trail.

Deep, thick lugs are excellent for digging into deep snow but may feel clumsy and offer less surface contact on a flat sheet of ice. Consider where you will spend most of your time.

Making the Right Choice for Your Goal

Select your winter footwear based on your most common winter activity.

- If your primary focus is urban commuting: Look for a flexible rubber sole with a dense, smaller tread pattern for reliable grip on potentially icy sidewalks.

- If your primary focus is outdoor recreation or hiking: Prioritize footwear with deep, aggressive treads (lugs) to handle uneven terrain and deep snow.

- If your primary focus is maximum safety on sheer ice: Consider specialized footwear with integrated metal studs or the ability to add removable traction cleats.

Ultimately, the right non-slip sole empowers you to navigate winter with confidence and stability.

Summary Table:

| Feature | Role in Winter Shoes |

|---|---|

| Material (Rubber) | Provides a high coefficient of friction for superior grip on slippery surfaces. |

| Tread Pattern | Engineered with edges to bite into ice and channels to disperse water and slush. |

| Pattern Size | Smaller, intricate patterns offer better slip resistance on flat, icy surfaces. |

| Key Benefit | Significantly reduces the risk of slips and falls on hazardous winter terrain. |

Need high-quality non-slip winter footwear for your customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and safe footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of non-slip shoes and boots, engineered with the optimal rubber compounds and tread patterns for maximum winter safety.

Let us help you equip your customers with the confidence to navigate winter safely. Contact our team today to discuss your manufacturing needs!

Visual Guide

Related Products

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

People Also Ask

- How do environmental conditions affect winter boots? Protect Your Boots from Winter's Worst

- What are the different heights available for winter boots and their uses? Find Your Perfect Fit

- What are the benefits of rubber hunting boots? Unmatched Waterproofing & Scent Control

- What is the function of the sole in outdoor shoes? Find the Perfect Grip and Support

- What are the best practices for storing winter boots? Preserve Your Investment for Next Season

- What are the reported benefits of USA-made hunting boots? Invest in Long-Lasting, High-Performance Footwear

- What are the boot requirements for warm and humid hunting conditions? Prioritize Breathability to Stay Cool

- What new technologies are emerging in winter cycling shoes? Stay Warm & Dry with Advanced Heating & Fit Systems