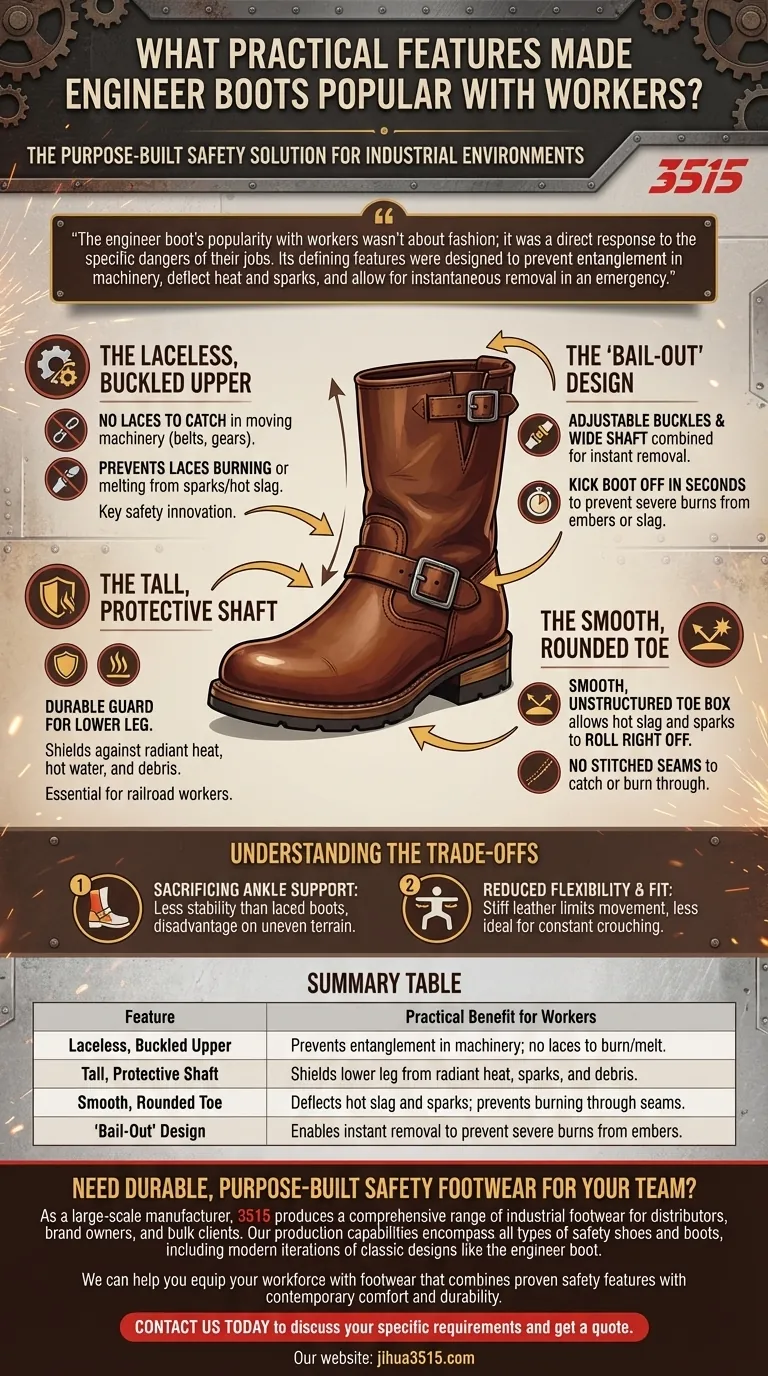

The practical appeal of engineer boots stemmed from three core features: a laceless design with adjustable buckles, a tall protective shaft, and a smooth, rounded toe. This combination was not an aesthetic choice but a purpose-built solution for workers in hazardous industrial environments who prioritized safety and rapid removal above all else.

The engineer boot's popularity with workers wasn't about fashion; it was a direct response to the specific dangers of their jobs. Its defining features were designed to prevent entanglement in machinery, deflect heat and sparks, and allow for instantaneous removal in an emergency.

The Anatomy of a Purpose-Built Safety Boot

Engineer boots solved specific, high-stakes problems for industrial workers. Every element of their design served a critical function, particularly in environments involving intense heat and heavy machinery.

The Laceless, Buckled Upper

The most defining feature is the absence of laces. This was a crucial safety innovation that prevented laces from getting caught in moving belts, gears, or other machinery, a common and severe workplace hazard.

It also eliminated a key vulnerability. Laces could easily burn through or melt when hit by welding sparks or hot slag, compromising the boot's integrity.

The "Bail-Out" Design

The adjustable buckles at the ankle and top of the shaft were not just for fit. Combined with the wide shaft, they allowed a worker to kick the boot off in seconds.

For welders, shipbuilders, and railroad firemen, this was a life-saving feature. If a piece of hot slag or a burning coal ember fell into the boot, the ability to remove it instantly was the only way to prevent a severe burn.

The Tall, Protective Shaft

The tall shaft, often made of double-layer leather, served as a durable guard for the lower leg.

This was essential for railroad workers tending to coal-fired steam engines, protecting them from radiant heat, hot water, and debris. It also shielded against general workplace hazards.

The Smooth, Rounded Toe

Unlike boots with moccasin-style stitching (moc toes), the engineer boot features a smooth, unstructured toe box.

This rounded surface was designed to let hot slag, sparks, and other molten materials roll right off. A stitched seam, by contrast, could catch a spark, allowing it to sit and burn through the leather.

Understanding the Trade-offs

While perfectly suited for certain jobs, the engineer boot's design presented clear disadvantages for others, leading to the popularity of different boot styles.

Sacrificing Ankle Support

The pull-on, laceless construction offers significantly less ankle support and stability than a tightly laced boot. For workers who needed to navigate uneven terrain or climb frequently, this was a considerable drawback.

Reduced Flexibility and Fit

The heavy, stiff leather of the tall shaft provides protection but limits flexibility. This made engineer boots less ideal for trades requiring constant crouching or agile movement, where a more pliable boot like a moc toe would be more comfortable.

Making the Right Choice for Your Goal

The engineer boot's design principles highlight its enduring value as a specialized tool.

- If your primary focus is protection from high heat and sparks: The combination of a laceless design, smooth toe, and rapid-removal capability is paramount.

- If your primary focus is preventing entanglement in machinery: The complete absence of laces is the most critical safety feature.

- If your primary focus is ankle support and all-day comfort for walking: A traditional lace-up boot, such as a moc toe, is likely a better-suited choice.

Ultimately, the engineer boot became an icon because it was an uncompromising solution to the deadly risks faced by the workers who wore it.

Summary Table:

| Feature | Practical Benefit for Workers |

|---|---|

| Laceless, Buckled Upper | Prevents entanglement in machinery; no laces to burn/melt. |

| Tall, Protective Shaft | Shields lower leg from radiant heat, sparks, and debris. |

| Smooth, Rounded Toe | Deflects hot slag and sparks; prevents burning through seams. |

| "Bail-Out" Design | Enables instant removal to prevent severe burns from embers. |

Need Durable, Purpose-Built Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including modern iterations of classic designs like the engineer boot.

We can help you equip your workforce with footwear that combines proven safety features with contemporary comfort and durability.

Contact us today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What is the core protective function of steel-toe safety shoes in preventing lower limb injuries caused by chainsaws?

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?

- Why are professional safety shoes required during heavy-duty girder erection? Essential Protection for Infrastructure

- What physical protections are provided by the S1 standard and integrated steel toecaps in industrial safety boots? Ensure Ultimate Foot Safety & Hazard Protection

- Why are industrial safety boots with steel toes necessary for machine operators? Essential Foot Protection for Safety