Workplace foot hazards extend far beyond the obvious risks of falling objects. The most common dangers include crushing from heavy items, punctures from sharp objects, slips on slick surfaces, burns from chemical or thermal sources, and electric shock from contact with live circuits.

Understanding the full spectrum of foot injury hazards requires looking beyond physical impacts. The true risk lies in the specific environment, where dangers can range from punctures and slips to unseen thermal, chemical, and electrical threats.

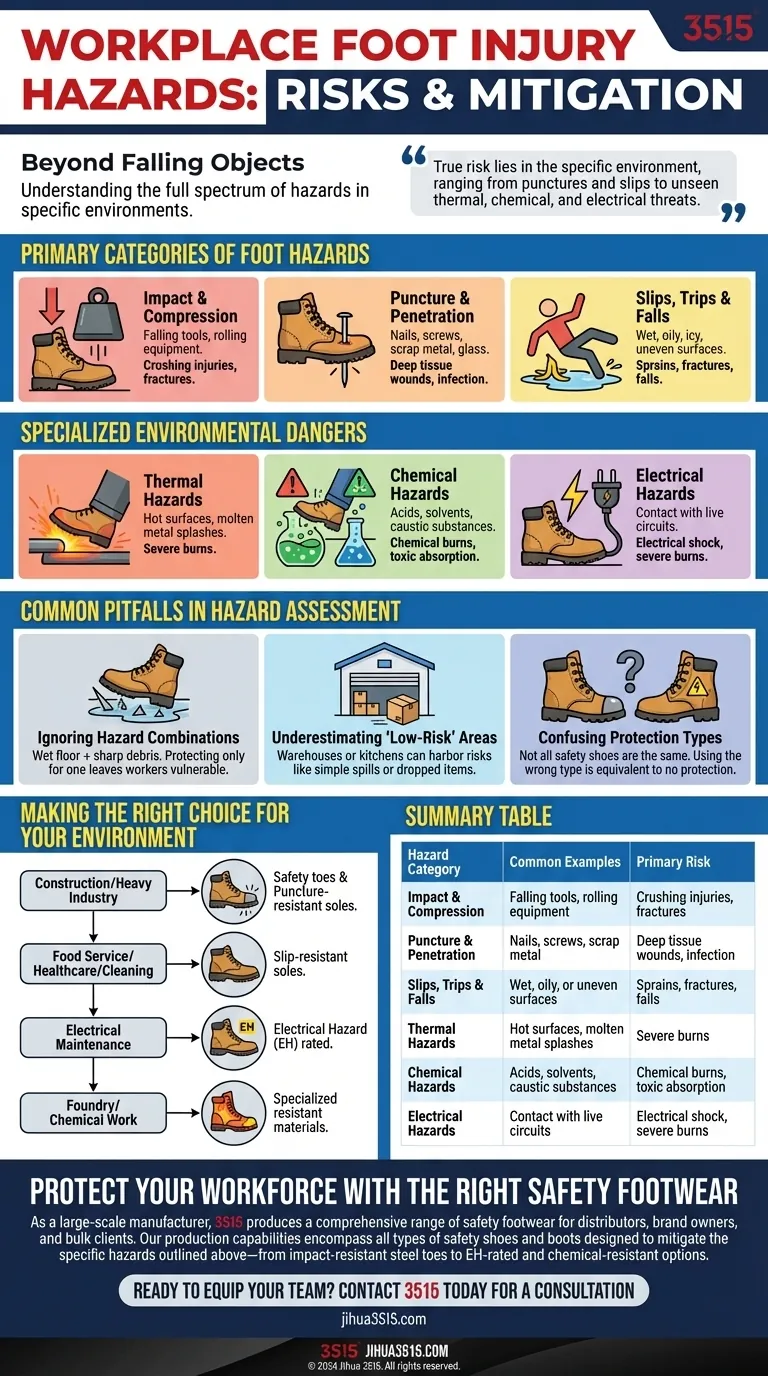

The Primary Categories of Foot Hazards

To properly mitigate risk, we must first categorize the distinct types of physical dangers present in a work environment. These are often the most frequent, though not always the most severe, causes of injury.

Impact and Compression

This is the most widely recognized foot hazard. It involves objects falling onto or rolling over the foot.

Heavy materials, tools dropped from a height, or moving equipment like pallet jacks can cause severe crushing injuries to the bones of the foot.

Puncture and Penetration

Floors in construction, demolition, or manufacturing settings are often littered with sharp objects.

Nails, screws, scrap metal, or shards of glass can easily penetrate the sole of standard footwear, leading to deep tissue wounds and infection.

Slips, Trips, and Falls

This category is one of the most common causes of all workplace injuries, often originating with the feet.

Wet, oily, or icy surfaces dramatically increase the risk of a fall. Uneven flooring or unseen obstacles can also lead to trips that cause sprains, fractures, or more severe impact injuries.

Specialized Environmental Dangers

Beyond direct physical trauma, the work environment itself can present specialized hazards that require specific types of protection to prevent severe, often irreversible, harm.

Thermal Hazards

Working near high-temperature operations creates a significant risk of burns.

This includes direct contact with hot surfaces or accidental splashes from molten metal, which can cause devastating injuries in an instant.

Chemical Hazards

Exposure to caustic substances can cause chemical burns or the absorption of toxic materials through the skin.

Properly rated footwear is essential to create a barrier against acids, solvents, and other hazardous chemicals that can degrade standard materials and reach the foot.

Electrical Hazards

For electricians or maintenance staff working near live electrical equipment, the risk of shock is a critical concern.

The foot can become a path to ground for an electrical current, leading to severe burns or electrocution. Specialized footwear is designed to insulate the wearer from these currents.

Common Pitfalls in Hazard Assessment

A superficial safety assessment can create a false sense of security. Recognizing common oversights is key to developing a robust safety protocol.

Ignoring Hazard Combinations

Many workplaces present multiple hazards simultaneously. A floor might be both wet and have sharp debris.

Selecting protection for only one type of hazard (e.g., puncture resistance) while ignoring another (e.g., slip resistance) leaves workers vulnerable.

Underestimating "Low-Risk" Areas

Seemingly safe environments like warehouses or kitchens can harbor significant risks.

A simple spill on a smooth concrete floor or a dropped box can be just as dangerous as the more obvious hazards of a construction site.

Confusing Protection Types

It is a critical mistake to assume all safety shoes are the same. A steel toe provides impact protection but does nothing for electrical or chemical hazards.

Each type of protection is engineered for a specific risk, and using the wrong type is equivalent to having no protection at all.

Making the Right Choice for Your Environment

Effective foot protection is not one-size-fits-all; it must be matched precisely to the known hazards of the job.

- If your primary focus is construction or heavy industry: Prioritize footwear with safety toes for impact and puncture-resistant soles.

- If your primary focus is food service, healthcare, or cleaning: Slip-resistant soles are the most critical feature to prevent falls on wet or slick surfaces.

- If your primary focus is electrical maintenance: Ensure footwear is officially rated for electrical hazard (EH) protection to insulate against shock.

- If your primary focus is foundry or chemical work: Select specialized boots made from materials designed to resist extreme heat or chemical permeation.

A thorough hazard analysis is the foundation of any effective workplace safety program.

Summary Table:

| Hazard Category | Common Examples | Primary Risk |

|---|---|---|

| Impact & Compression | Falling tools, rolling equipment | Crushing injuries, fractures |

| Puncture & Penetration | Nails, screws, scrap metal | Deep tissue wounds, infection |

| Slips, Trips & Falls | Wet, oily, or uneven surfaces | Sprains, fractures, falls |

| Thermal Hazards | Hot surfaces, molten metal splashes | Severe burns |

| Chemical Hazards | Acids, solvents, caustic substances | Chemical burns, toxic absorption |

| Electrical Hazards | Contact with live circuits | Electrical shock, severe burns |

Protect Your Workforce with the Right Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots designed to mitigate the specific hazards outlined above—from impact-resistant steel toes to EH-rated and chemical-resistant options.

We help you ensure compliance, enhance worker safety, and reduce workplace injuries by providing durable, purpose-built footwear tailored to your unique environmental risks.

Ready to equip your team with reliable protection? Contact 3515 today for a consultation and let us help you make the right choice for your safety needs.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision