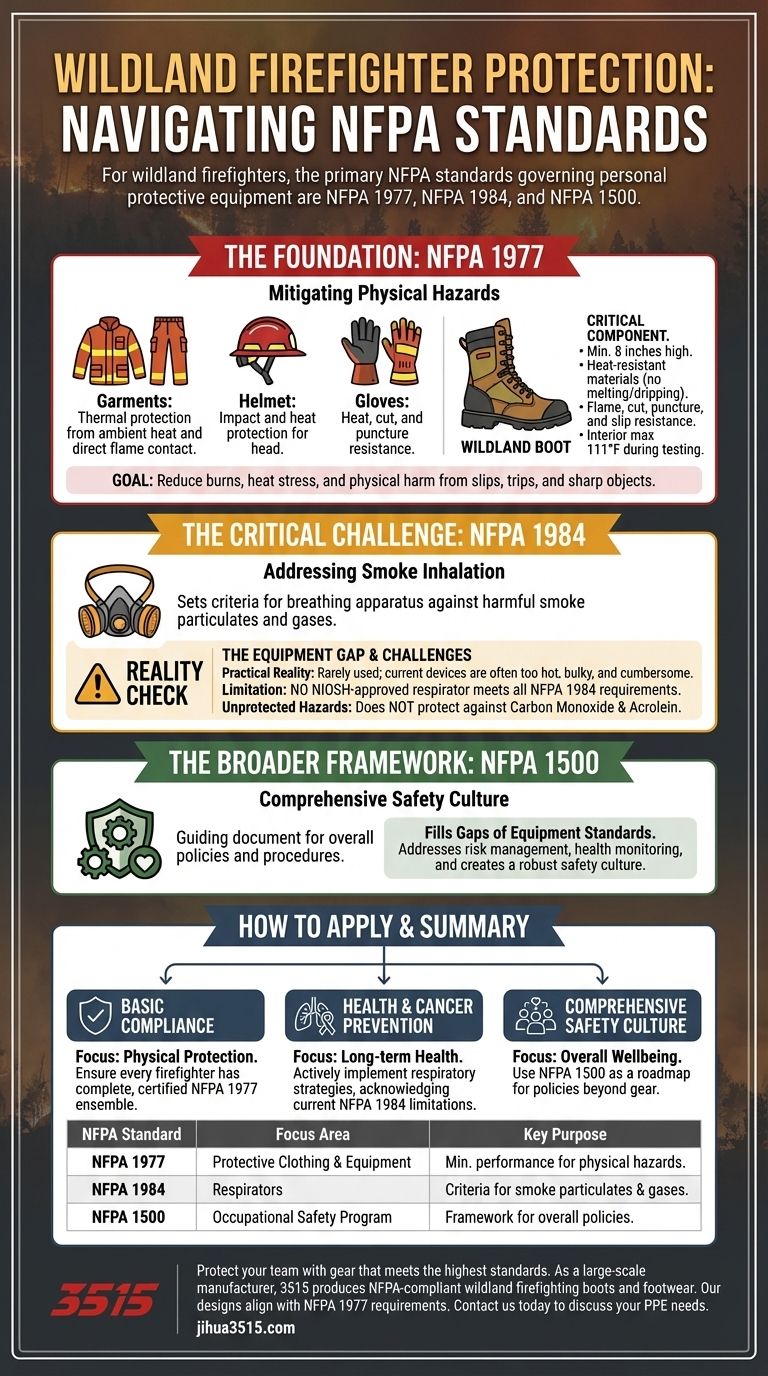

For wildland firefighters, the primary NFPA standards governing personal protective equipment are NFPA 1977 for protective clothing and equipment, NFPA 1984 for respirators, and NFPA 1500 for the overall occupational safety program. These standards set the minimum performance requirements for gear designed to protect against the unique physical and environmental hazards of wildland firefighting.

Understanding the relevant NFPA standards is about more than just compliance. It requires recognizing that while standards exist for physical gear, significant gaps remain between the requirements and the practical realities of mitigating long-term health risks like smoke inhalation on the fire line.

The Foundation: NFPA 1977 for Protective Gear

NFPA 1977 is the core standard for wildland personal protective equipment (PPE). It focuses on protecting the wearer from the immediate physical dangers of the environment.

What NFPA 1977 Covers

This standard specifies the minimum design, performance, testing, and certification requirements for protective garments, helmets, gloves, and footwear. Its goal is to provide thermal protection from ambient heat and direct flame contact.

A Closer Look at Footwear

Footwear is a critical component addressed in detail. NFPA 1977 requires wildland boots to be a minimum of 8 inches high and constructed with heat-resistant materials that do not melt, drip, or delaminate under high temperatures.

Key requirements include flame resistance, cut and puncture resistance in the upper portion, and slip-resistant soles that can withstand conductive heat, ensuring the boot's interior does not exceed 111°F in testing. All components, from thread to eyelets, must be heat-resistant and durable.

The Goal: Mitigating Physical Hazards

The ultimate purpose of NFPA 1977 is to reduce the risk of common wildland injuries. This includes burns, heat-related stress, and physical harm from slips, trips, falls, and contact with sharp objects on the fire line.

The Critical Challenge: Respiratory Protection

While physical injury is an immediate threat, the long-term health effects of smoke inhalation are a growing concern. NFPA 1984 addresses the equipment designed to mitigate this risk.

The Standard: NFPA 1984

NFPA 1984 sets the standard for respirators used during wildland fire suppression. It outlines performance criteria for breathing apparatus intended to protect against the harmful particulates and gases found in smoke.

The Reality on the Fire Line

Despite the existence of a standard, respirators are not commonly used by wildland firefighters. The primary reason is practical: current devices are often seen as too hot, bulky, and cumbersome for the strenuous physical work and high ambient temperatures of a wildland fire.

The Equipment Gap

A significant challenge is that no NIOSH-approved respirator currently meets all the requirements of the NFPA 1984 standard. Furthermore, even approved respirators do not protect against all hazards, notably carbon monoxide and acrolein, two dangerous components of wildland smoke.

Understanding the Gaps and Limitations

Being a trusted advisor means being honest about where the standards fall short. Simply complying with existing rules does not eliminate all risks.

The Absence of Administrative Controls

A major gap is the lack of any specific NFPA standard that addresses administrative controls for wildland fire exposures. This includes critical health and safety protocols like mandatory work-to-rest cycles, exposure tracking, or defined limits for smoke inhalation.

The Focus on Gear vs. Exposure

Current standards are heavily focused on the performance and testing of physical equipment. They are less effective at guiding departments on how to manage the duration and intensity of a firefighter's exposure to carcinogenic smoke and other systemic health threats.

The Broader Framework: NFPA 1500

NFPA 1500, Standard on Fire Department Occupational Safety, Health, and Wellness Program, provides a broad framework for creating a comprehensive safety culture. While not specific to wildland operations, it is the guiding document for building the policies and procedures that can begin to fill the gaps left by equipment-focused standards.

How to Apply This to Your Department

Your approach should be dictated by your specific safety and operational goals. Use these standards as a foundation, not a ceiling.

- If your primary focus is basic compliance and physical protection: Ensure every firefighter is issued a complete ensemble of clothing and equipment that is certified to meet or exceed all requirements of NFPA 1977.

- If your primary focus is long-term health and cancer prevention: Actively investigate and implement respiratory protection strategies that fit your operational context, even with the current limitations of equipment under NFPA 1984.

- If your primary focus is building a comprehensive safety culture: Use NFPA 1500 as your roadmap to develop robust policies that address risk management, health monitoring, and administrative controls that go far beyond just gear.

Understanding these standards and their real-world limitations is the first step toward truly safeguarding the health and safety of your firefighters.

Summary Table:

| NFPA Standard | Focus Area | Key Purpose |

|---|---|---|

| NFPA 1977 | Protective Clothing & Equipment | Sets minimum performance for garments, helmets, gloves, and boots against physical hazards. |

| NFPA 1984 | Respirators | Establishes criteria for breathing apparatus to protect against smoke particulates and gases. |

| NFPA 1500 | Occupational Safety Program | Provides a framework for overall safety, health, and wellness policies in fire departments. |

Protect your team with gear that meets the highest standards. As a large-scale manufacturer, 3515 produces NFPA-compliant wildland firefighting boots and footwear for distributors, brand owners, and bulk clients. Our heat-resistant, durable designs align with NFPA 1977 requirements to safeguard against physical hazards. Contact us today to discuss your PPE needs and enhance your department's safety.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What role does the YOLOv3 object detection algorithm play in smart obstacle avoidance shoes? Real-Time Visual AI

- What is the recommended care routine for leather riding boots? Keep Your Boots in Peak Condition

- What role does a smart insole system play in overground walking rehabilitation training? Enhance Robotic Gait Precision

- When was Cordura first introduced and what was its initial use? From 1967 Nylon to Modern Toughness

- In which disciplines are field boots commonly used? Essential Footwear for Hunter, Jumper & Eventing Riders

- What footwear is recommended for day rides in mountain biking during winter? Maximize Warmth & Performance

- What role do high-frequency 3D force plates play in dynamic postural stability testing? Precision Balance Analysis

- What protective function does a forefoot decompression shoe provide? Essential Recovery Insights for Orthopedic Surgery