To be precise, Cordura's history has two key dates. The original material, a type of rayon, was developed by DuPont in 1929. However, the high-performance, exceptionally durable nylon fabric that Cordura is famous for today was introduced in 1967, with its initial uses focused on military applications and heavy-duty outdoor gear.

The name "Cordura" represents two distinct materials: an early rayon developed for industrial use in 1929 and a revolutionary nylon fabric introduced in 1967. It was this later version that built Cordura's modern reputation for unparalleled toughness.

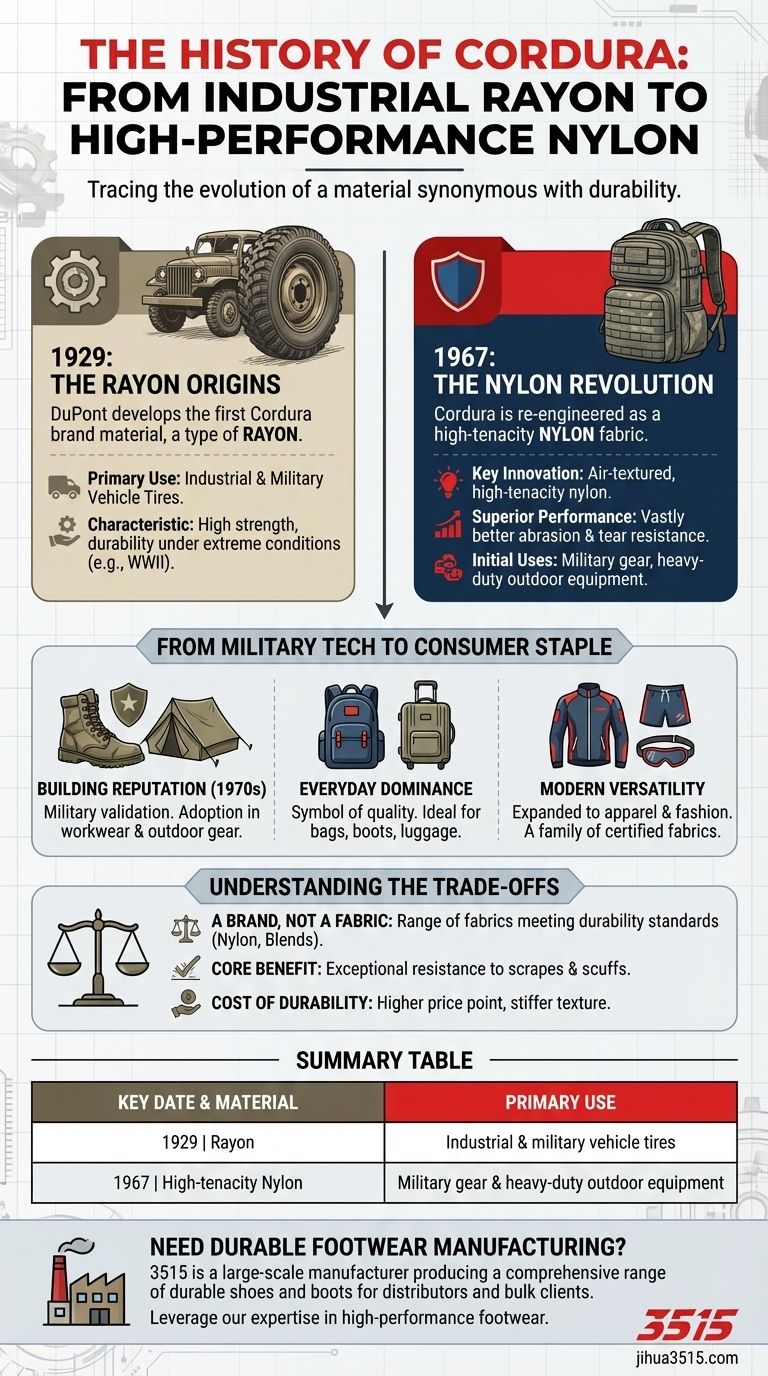

The Two Eras of Cordura

Understanding Cordura requires recognizing its evolution from an industrial material into a high-performance textile. The name has been constant, but the underlying technology has changed dramatically.

The Rayon Origins (1929)

DuPont first successfully developed a fabric under the Cordura brand in 1929.

This initial version was a type of rayon, a semi-synthetic fiber. Its primary characteristic was high strength, which led to its adoption for industrial and military purposes.

During World War II, this original Cordura found a critical role as a material used within military vehicle tires, proving its durability under extreme conditions.

The Nylon Revolution (1967)

In the mid-1960s, the brand underwent a fundamental transformation. Chemists re-engineered Cordura as a nylon-based fabric.

This new formulation, introduced in 1967, possessed vastly superior abrasion resistance and tear strength compared to its rayon predecessor and even standard nylon.

It is this air-textured, high-tenacity nylon fabric that became the gold standard for durable gear and established the brand's modern identity.

From Military Tech to Consumer Staple

The adoption of the new nylon Cordura was swift, cementing its reputation in markets where failure was not an option.

Building a Reputation for Toughness

The military was among the first to adopt the new nylon Cordura for a wide range of gear, validating its performance in the most demanding environments.

By the 1970s, this proven toughness caught the attention of the civilian market. Brands specializing in workwear and outdoor equipment began using it extensively.

Dominance in Everyday Gear

The fabric's resilience made it the ideal choice for products that endure constant abuse, such as backpacks, luggage, and boots.

Its success in these categories made the Cordura tag a recognizable symbol of quality and longevity for consumers worldwide.

Modern Versatility

Today, Cordura refers to a family of certified fabrics. While still a staple in military and outdoor gear, its applications have expanded into performance apparel and even fashion accessories where durability is a key selling point.

Understanding the Trade-offs

While renowned for its strength, it's important to understand the context of Cordura's performance.

A Brand, Not a Single Fabric

"Cordura" is a brand name for a range of fabrics that meet specific durability standards. Most are nylon, but some are blends of synthetic and cotton fibers.

The Core Benefit: Abrasion Resistance

The primary advantage of Cordura over many other synthetics is its exceptional resistance to scrapes, scuffs, and general wear and tear. This is why it excels in bags and outerwear.

The Cost of Durability

This ruggedness often comes with a higher price point and a stiffer fabric texture compared to less durable materials. For applications where softness or low cost is the priority, Cordura might be overkill.

Why This History Matters for Your Choice

The dual history of Cordura is not just trivia; it explains the brand's deep-rooted association with durability.

- If your primary focus is historical accuracy: Acknowledge that the Cordura name originated in 1929 with rayon, but the fabric we value today was born in 1967 as nylon.

- If your primary focus is material performance: The 1967 nylon reinvention is the definitive starting point for the high-performance textile used in modern gear.

Ultimately, Cordura's legacy is defined by decades of proven performance in the world's toughest applications.

Summary Table:

| Key Date | Material | Primary Use |

|---|---|---|

| 1929 | Rayon | Industrial & military vehicle tires |

| 1967 | High-tenacity Nylon | Military gear & heavy-duty outdoor equipment |

Need a reliable supply of durable footwear built to last?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots, perfect for workwear and outdoor markets that demand Cordura-level toughness.

Contact us today to discuss your manufacturing needs and leverage our expertise in high-performance footwear.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Lightweight Tactical Boots Custom Manufacturer for Desert & Combat Use

- Durable High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- Why is high-elasticity midsole structural design important? Enhance Performance with Mechanical Aesthetics

- Why is EVA used with carbon fiber plates in footwear? Balancing Rigidity and Comfort for Peak Performance

- What strategic considerations should owners of specialty footwear brands prioritize when selecting influencers?

- How do leather patches function as branding & customizable components? Enhancing Identity in Apparel Assembly

- What role do 3D CAD tools play in the design of depth shoe lasts for diabetic patients? Precision Digital Engineering

- What are the advantages of foot-mounted Integrated IMUs? Unlock Precision Biomechanics for Footwear R&D

- Why are Intrinsically Conductive Polymers such as PEDOT or PANI regarded as more sustainable for smart footwear textiles?

- What makes KPU material environmentally friendly? A Solvent-Free Path to Cleaner Manufacturing