At their core, police boots are constructed from a strategic combination of materials like full-grain leather, high-strength nylon fabrics, and durable rubber or polyurethane for the soles. This blend isn't accidental; it's engineered to provide a critical balance of durability for demanding conditions, support for long hours on foot, and protection from the elements.

The choice of materials in a police boot is a direct reflection of its intended function. Each component, from rugged leather uppers to breathable waterproof liners, is selected to meet the specific operational demands of an officer's job, balancing protection with mobility and comfort.

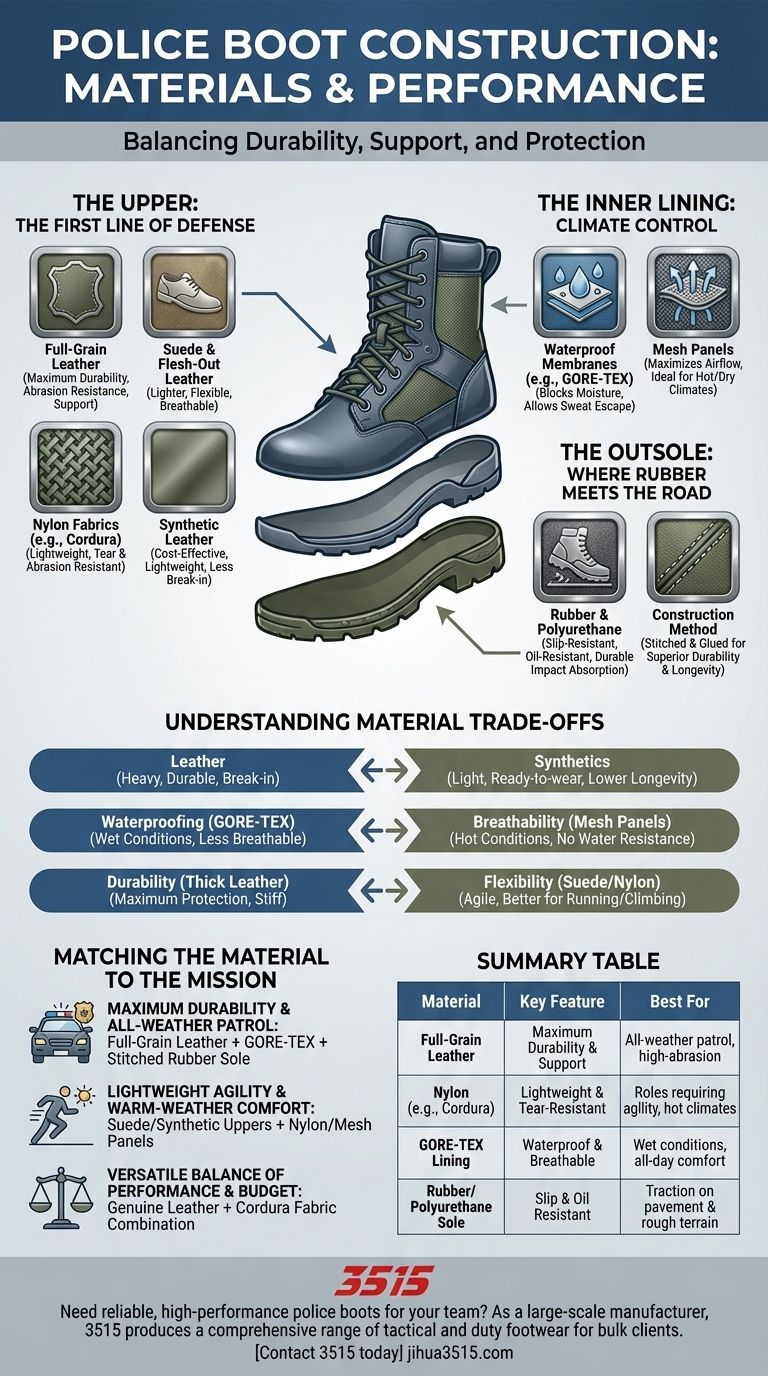

The Anatomy of a Police Boot: A Material Breakdown

A police boot's performance is determined by the materials used in its key sections: the upper, the inner lining, and the outsole. Each part serves a distinct purpose and requires specific material properties.

The Upper: The First Line of Defense

The upper portion of the boot faces the most direct wear and environmental exposure.

Full-Grain Leather is the classic choice, prized for its exceptional durability, abrasion resistance, and natural water resistance. It provides excellent support and can be polished for a professional appearance.

Suede and Flesh-Out Leather are lighter and more flexible than full-grain leather. They offer good durability and breathability, making them suitable for hotter climates or roles requiring more agility.

Nylon Fabrics, such as Cordura, are often integrated into leather uppers. These synthetic textiles dramatically reduce weight while adding incredible tear and abrasion resistance.

Synthetic Leather is a cost-effective and lightweight alternative to real leather. While it requires less break-in time, it typically offers lower long-term durability and breathability.

The Inner Lining: Climate Control

What's inside the boot is just as important as the outside, especially for all-day comfort.

Waterproof Membranes like GORE-TEX are a critical feature in many modern police boots. This specialized layer blocks external moisture from entering the boot while allowing sweat vapor to escape, keeping feet dry and comfortable.

Mesh Panels are often added to the exterior of non-waterproof boots to maximize airflow. This is a key feature for boots designed for use in hot, dry environments.

The Outsole: Where Rubber Meets the Road

The outsole dictates the boot's traction, stability, and overall longevity.

Rubber and Polyurethane are the most common materials for outsoles. They are formulated to be slip-resistant, oil-resistant, and highly durable to withstand constant impact on pavement and rough terrain.

Construction Method is also a key material consideration. Soles that are both stitched and glued to the upper are significantly more durable and less prone to separation than those that are only glued.

Understanding the Material Trade-offs

Selecting the right boot means understanding the inherent compromises between different materials. No single boot is perfect for every situation.

Leather vs. Synthetics

Full-grain leather offers maximum durability but is often heavier and requires a break-in period. Synthetics and nylon are lightweight and ready to wear out of the box but may not last as long under heavy use.

Waterproofing vs. Breathability

A fully waterproof boot with a membrane like GORE-TEX is excellent for wet conditions but can be warmer and less breathable in a hot, arid climate. A boot with mesh panels will offer superior breathability at the cost of any water resistance.

Durability vs. Flexibility

A rugged, stiff boot made entirely of thick leather provides maximum protection and ankle support. However, a lighter boot that incorporates suede or large nylon panels will offer far greater flexibility for tasks that involve running or climbing.

Matching the Material to the Mission

Your choice should be dictated by your primary operational environment and daily tasks.

- If your primary focus is maximum durability and all-weather patrol: Look for full-grain leather uppers combined with a GORE-TEX waterproof membrane and a stitched rubber outsole.

- If your primary focus is lightweight agility and warm-weather comfort: Prioritize boots with suede or synthetic uppers that incorporate extensive nylon or mesh panels for breathability.

- If your primary focus is a versatile balance of performance and budget: A boot made from a combination of genuine leather and durable Cordura fabric offers a reliable and proven middle ground.

Ultimately, understanding these core materials empowers you to select a boot not just by its appearance, but by its fundamental ability to perform when it matters most.

Summary Table:

| Material | Key Feature | Best For |

|---|---|---|

| Full-Grain Leather | Maximum Durability & Support | All-weather patrol, high-abrasion environments |

| Nylon (e.g., Cordura) | Lightweight & Tear-Resistant | Roles requiring agility, hot climates |

| GORE-TEX Lining | Waterproof & Breathable | Wet conditions, all-day comfort |

| Rubber/Polyurethane Sole | Slip & Oil Resistant | Traction on pavement and rough terrain |

Need reliable, high-performance police boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of tactical and duty footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of boots, engineered with the precise material combinations detailed above to meet the demanding needs of law enforcement.

We ensure durability, comfort, and protection in every pair. Let us help you equip your force with footwear that performs when it matters most.

Contact 3515 today to discuss your specific requirements and receive a custom quote.

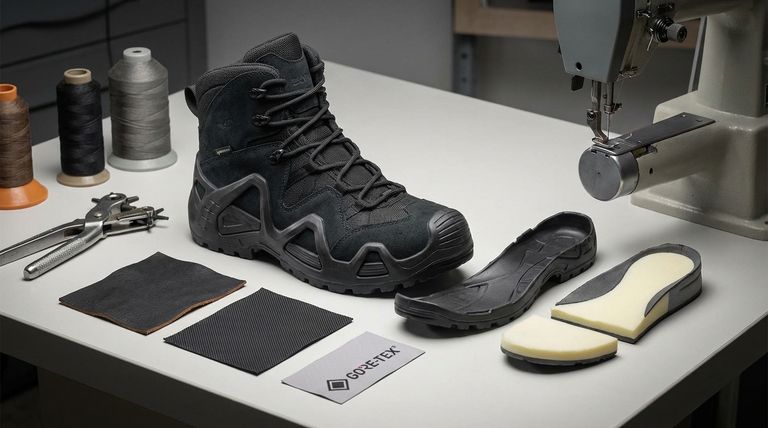

Visual Guide

Related Products

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What are station boots used for? The Essential Footwear for Firefighter Station Life

- Which police boots are best? Find the Perfect Fit for Your Mission

- What protection and safety features do police boots offer? Engineered for Maximum Officer Safety

- What are the features of service boots? A Guide to the Classic Rugged & Versatile Boot

- Why are waterproof boots important for police officers? Ensuring Health, Mobility, and Readiness

- What are the Forest Service standards for fire-safe boots? Essential NFPA 1977 Requirements

- What are the key features of police boots? Essential Safety & Comfort for Demanding Duty

- What are the main types of police footwear? A Guide to Durable & Specialized Footwear