To meet U.S. Forest Service standards, a wildland fire boot must be a minimum of 8 inches tall, constructed of all leather, and feature a melt-resistant, Vibram-type lug sole. These non-negotiable requirements are designed to provide firefighters with critical protection from heat, ankle support on treacherous terrain, and reliable traction when it matters most.

The core standards for fire boots are not arbitrary rules; they represent a system of safety engineered from decades of experience. Understanding the "why" behind each requirement is crucial for ensuring your gear provides maximum protection and performance on the fire line.

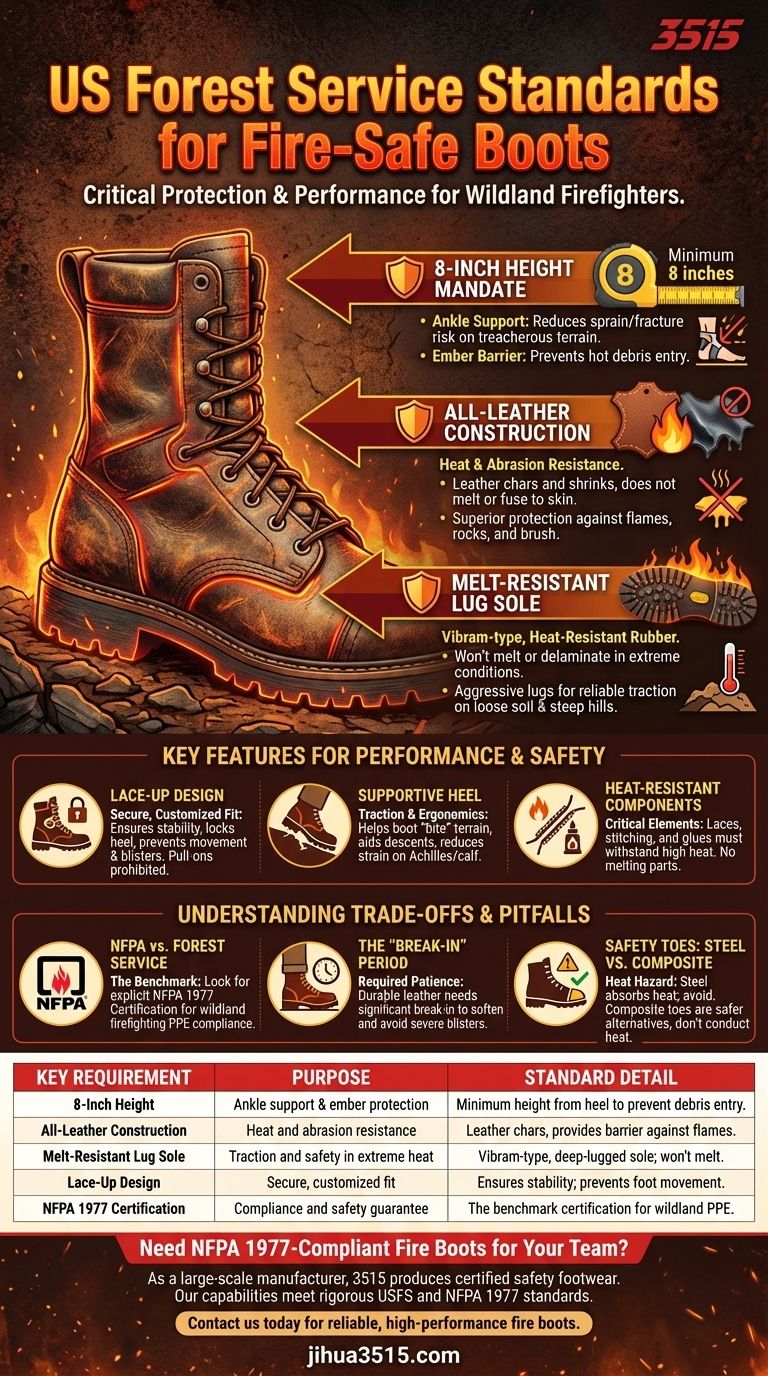

Deconstructing the Core Requirements

The three primary standards—height, material, and sole—work together to create a protective barrier against the unique hazards of a wildland fire environment. Each one serves a specific, life-saving purpose.

The 8-Inch Height Mandate

The minimum 8-inch height from the bottom of the heel is critical for two reasons. First, it provides essential ankle support, reducing the risk of sprains and fractures when navigating steep, uneven, and unstable ground.

Second, this height creates a barrier that prevents hot embers, ash, and sharp debris from falling into the boot, which could cause severe burns or injury.

All-Leather Construction

The requirement for an all-leather exterior is based on its natural durability and resistance to heat. Unlike synthetic fabrics, which can melt and fuse to the skin when exposed to high temperatures, leather tends to char and shrink.

This provides a vital layer of protection against direct flame contact and radiant heat. Leather also offers superior abrasion resistance against rocks and brush.

The Melt-Resistant Lug Sole

The sole of a fire boot must be made from a heat-resistant rubber compound that will not melt or delaminate in extreme conditions. A boot failure on the fire line is a catastrophic event.

The standard often specifies a Vibram-type sole, which refers to a specific design known for its deep, aggressive lugs. This lug pattern is essential for providing reliable traction on loose soil, rock, and steep hillsides.

Key Features for Performance and Safety

Beyond the foundational standards, several other design features are crucial for a boot to be effective and safe for firefighting.

Lace-Up Design for a Secure Fit

Forest Service and NFPA standards explicitly require a lace-up boot. Pull-on styles, like Wellingtons, are not permitted because they cannot provide the secure, customized fit necessary for stability.

A properly laced boot locks the heel in place, supports the ankle, and prevents the foot from shifting, which is critical for preventing blisters and maintaining balance.

A Supportive Heel

A well-defined, supportive heel is a key component for traction and ergonomics. It helps the boot "bite" into the terrain, especially during descents, reducing the likelihood of a slip or fall.

This structure also helps reduce strain on the Achilles tendon and calf muscles over long, arduous shifts.

Heat-Resistant Components

Every part of the boot must be designed to withstand high heat. This includes the laces, stitching, and any glues used in its construction. Components that melt or ignite create a significant safety hazard.

Understanding the Trade-offs and Pitfalls

Selecting the right boot involves more than just meeting a checklist. You must be aware of the context and potential issues to ensure you are truly prepared.

NFPA vs. Forest Service Standards

The Forest Service requirements align directly with the standards set by the National Fire Protection Association (NFPA). NFPA certification is the benchmark for wildland firefighting personal protective equipment (PPE).

When choosing a boot, look for one that is explicitly NFPA 1977 certified, as this guarantees it meets all the necessary safety protocols for use in a wildland environment.

The "Break-In" Period

A heavy-duty leather fire boot is not comfortable out of the box. These boots are built with thick, durable leather that requires a significant "break-in" period to soften and conform to your foot.

Failing to properly break in your boots before deployment can lead to severe blisters and foot pain that can compromise your effectiveness and safety.

The Role of Safety Toes

While impact protection is important, traditional steel-toed boots are often discouraged for firefighting. Steel can absorb and retain heat, creating a burn risk long after you've left a hot area.

If a safety toe is required, a composite toe is a much safer alternative as it does not conduct heat.

Making the Right Choice for Your Mission

Your final boot selection should be guided by the non-negotiable standards while also considering the specific demands of your role.

- If your primary focus is compliance: Ensure the boot is explicitly NFPA 1977 certified and meets the three core requirements: 8-inch leather construction with a melt-resistant lug sole.

- If your primary focus is performance on rugged terrain: Look for a boot with an aggressive, deep-lugged sole and a reinforced heel for maximum traction and stability.

- If your primary focus is long-term comfort and foot health: Choose a boot with features from high-end hiking footwear and dedicate ample time to breaking it in properly before the fire season begins.

Ultimately, your boots are one of the most critical pieces of safety equipment you have, connecting you directly to the hazardous ground you work on.

Summary Table:

| Key Requirement | Purpose | Standard Detail |

|---|---|---|

| 8-Inch Height | Ankle support & ember protection | Minimum height from heel to prevent debris entry and injuries. |

| All-Leather Construction | Heat and abrasion resistance | Leather chars instead of melting, providing a critical barrier against flames. |

| Melt-Resistant Lug Sole | Traction and safety in extreme heat | Vibram-type, deep-lugged sole that won't melt or delaminate. |

| Lace-Up Design | Secure, customized fit | Ensures stability and prevents foot movement on unstable terrain. |

| NFPA 1977 Certification | Compliance and safety guarantee | The benchmark certification for wildland firefighting PPE. |

Need NFPA 1977-Compliant Fire Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of wildland fire boots that meet the rigorous USFS and NFPA 1977 standards, ensuring maximum protection and performance for firefighters.

Contact us today to discuss your specific requirements and get a quote for reliable, high-performance fire boots.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What types of protection should law enforcement boots offer? Essential Safety Features for Officers

- What is the Climate System in police tactical boots? A Guide to All-Weather Foot Comfort

- Why are waterproof boots important for police officers? Ensuring Health, Mobility, and Readiness

- What are the key features to look for in police tactical boots? A Guide to Safety, Durability & Comfort

- Why is it important for emergency responders to wear NFPA-approved boots? Ensure Maximum Protection

- How are motorcycle police boots designed? A Deep Dive into Purpose-Built Footwear for Law Enforcement

- How do well-designed law enforcement boots improve job performance? Enhance Officer Safety and Agility

- What are the key features of patrol boots? Lightweight & Flexible for Maximum Mobility