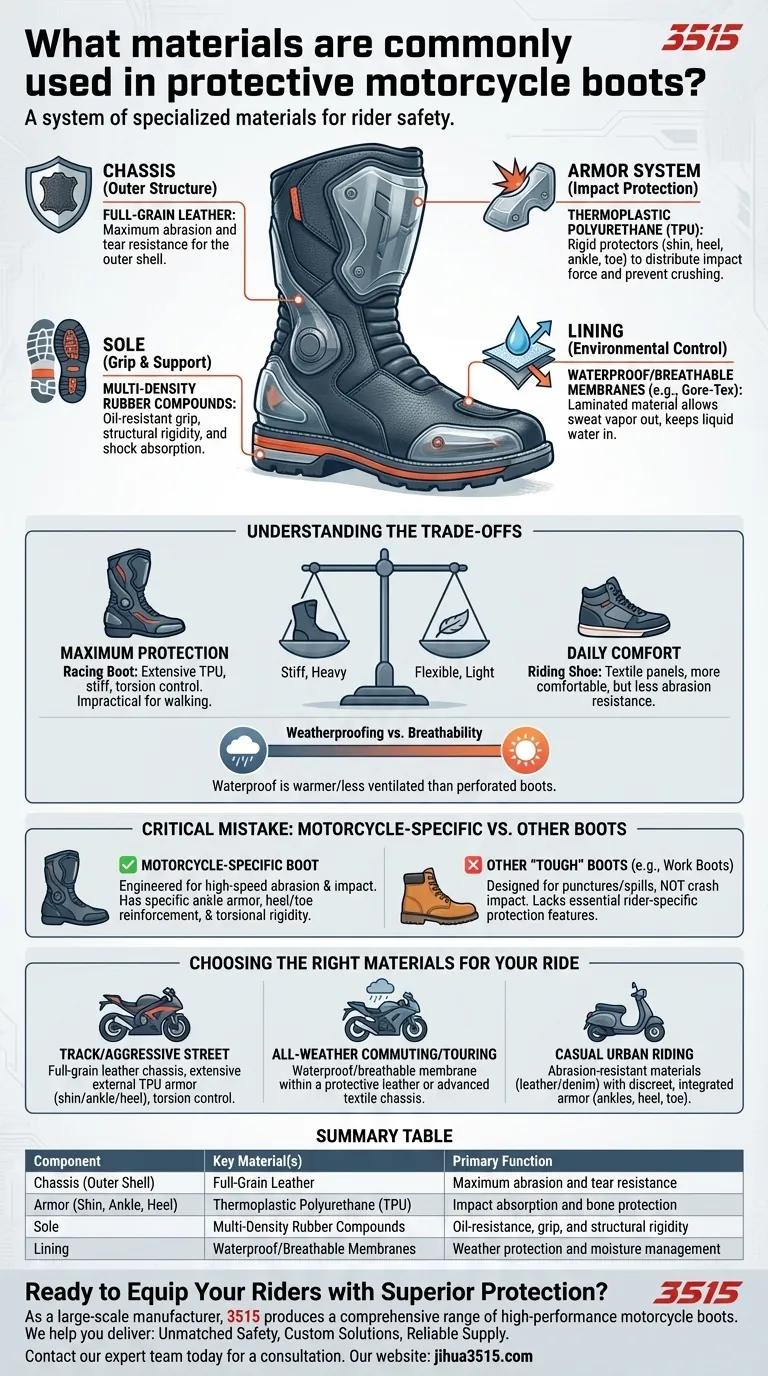

At their core, protective motorcycle boots are constructed from a system of specialized materials designed for distinct purposes. The most common materials are full-grain leather for abrasion resistance, advanced polymers like TPU for impact armor, waterproof/breathable membranes such as Gore-Tex, and multi-density rubber compounds for the sole.

The key takeaway is that a truly protective boot is not defined by a single material, but by how different materials are intelligently integrated into a system that provides abrasion resistance, impact absorption, and structural support without catastrophic failure.

The Anatomy of a Protective Boot

A motorcycle boot is an engineered piece of safety equipment. Each material is chosen to solve a specific problem a rider faces during a crash or even just during normal operation.

The Chassis: Abrasion Resistance

The outer structure, or chassis, of the boot has one primary job: to resist being worn away by abrasive surfaces like asphalt.

Full-grain leather is the gold standard for this purpose. Its dense, interlocking fiber structure is exceptionally durable and resists tearing and abrasion far better than textiles or lesser grades of leather.

The Armor System: Impact Protection

Hard armor is integrated at critical points to protect your bones from crushing and impact forces. This is where advanced plastics and polymers are essential.

Materials like Thermoplastic Polyurethane (TPU) are used to create rigid protectors for the shin, heel cup, ankle, and toe box. This armor is designed to distribute the force of an impact over a wider area and prevent crushing injuries. A CE-rated boot, for example, can often withstand immense pressure.

The Sole: Grip, Support, and Feel

The sole of a motorcycle boot serves multiple functions, requiring a blend of materials.

Most quality boots use a dual or triple-density rubber sole. Different compounds provide oil-resistance for grip, rigidity to prevent the boot from folding around a footpeg in a crash, and a degree of shock absorption for comfort when walking.

The Lining: Environmental Control

For riders who face varied weather, the boot's internal lining is a critical component for comfort and safety.

Waterproof and breathable membranes, with Gore-Tex being the most well-known, are laminated to the boot's interior. This material uses micropores large enough to let water vapor (sweat) out but too small to let liquid water in, keeping your feet dry.

Understanding the Trade-offs

No single boot is perfect for every situation. The choice of materials always involves a balance between maximum protection, comfort, and weather resistance.

Protection vs. Flexibility

A top-tier racing boot with extensive external TPU armor and torsion control systems offers maximum protection. However, these features make the boot stiff and often impractical for walking more than a few steps.

Conversely, a "riding shoe" may use more comfortable textile panels but offers significantly less impact and abrasion resistance than a full-grain leather boot.

Weatherproofing vs. Breathability

A boot with a waterproof membrane is excellent for touring or commuting in the rain.

The trade-off is that even the most breathable membranes will be warmer and less ventilated than a non-waterproof, perforated boot designed for hot summer days. Using the wrong boot for the climate can lead to significant discomfort.

Motorcycle-Specific vs. Other "Tough" Boots

It is a critical mistake to assume other heavy-duty footwear, like work boots, offers equivalent protection.

Work boots are made from rubber or PVC and are designed for puncture resistance or chemical spills, not high-speed abrasion and impact. They lack the specific ankle armor, heel and toe reinforcement, and torsional rigidity required for riding.

Choosing the Right Materials for Your Ride

Your ideal boot depends entirely on your primary type of riding.

- If your primary focus is track riding or aggressive street riding: Seek out a boot with a full-grain leather chassis, extensive external TPU armor on the shin, heel, and ankle, and a torsion control system.

- If your primary focus is all-weather commuting or touring: Prioritize a boot with a reputable waterproof and breathable membrane layered within a protective leather or advanced textile chassis.

- If your primary focus is casual urban riding: Look for abrasion-resistant materials (leather or riding-specific denim) with discreet, integrated armor at the ankles, heel, and toe.

Ultimately, selecting the right boot is about matching the materials and their protective capabilities to the real-world risks of your specific riding environment.

Summary Table:

| Component | Key Material(s) | Primary Function |

|---|---|---|

| Chassis (Outer Shell) | Full-Grain Leather | Maximum abrasion and tear resistance |

| Armor (Shin, Ankle, Heel) | Thermoplastic Polyurethane (TPU) | Impact absorption and bone protection |

| Sole | Multi-Density Rubber Compounds | Oil-resistance, grip, and structural rigidity |

| Lining | Waterproof/Breathable Membranes (e.g., Gore-Tex) | Weather protection and moisture management |

Ready to Equip Your Riders with Superior Protection?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance motorcycle boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, engineered with the precise material systems detailed above to ensure rider safety and comfort.

We help you deliver:

- Unmatched Safety: Boots built with CE-rated armor and abrasion-resistant materials.

- Custom Solutions: Tailored designs for sport, touring, or urban riding markets.

- Reliable Supply: Consistent, high-volume manufacturing to meet your demand.

Let's discuss your specific needs and how we can build a safer riding experience together.

Contact our expert team today for a consultation

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What are common signs of wear and tear in motorcycle boots? Identify Critical Safety Failures

- What are the durability requirements for walking shoes? Select the Right Shoe for Long-Lasting Comfort

- What mechanisms do walking boots use to immobilize the foot and ankle? A Guide to Effective Healing

- How can hunters manage scent control with their boots? A Complete Guide to Eliminating Odor

- What are the functional differences between winter boots and snow boots? Choose the Right Boot for Your Winter Needs

- What additional benefit do most waterproof motorcycle boots offer besides keeping feet dry? Breathability for All-Day Comfort.

- What are common stress points on tall boots and how can they be addressed? Maximize Your Boot's Lifespan

- Which type of boot is more expensive: waterproof or water-resistant? Unpacking the Cost of True Protection