At its core, a Goodyear welted shoe is a system of specific, high-quality materials chosen for durability and repairability. The primary components are a strong leather welt that forms the shoe's foundation, a cork filler in the cavity between the insole and outsole for custom-molding comfort, and premium leather uppers such as full-grain calfskin. A rigid internal shank provides structural support.

The materials in a Goodyear welted shoe are not interchangeable; they are selected as part of an integrated system. This construction method prioritizes longevity and a personalized fit, where each component—from the leather to the cork—plays a critical role in the shoe's performance over time.

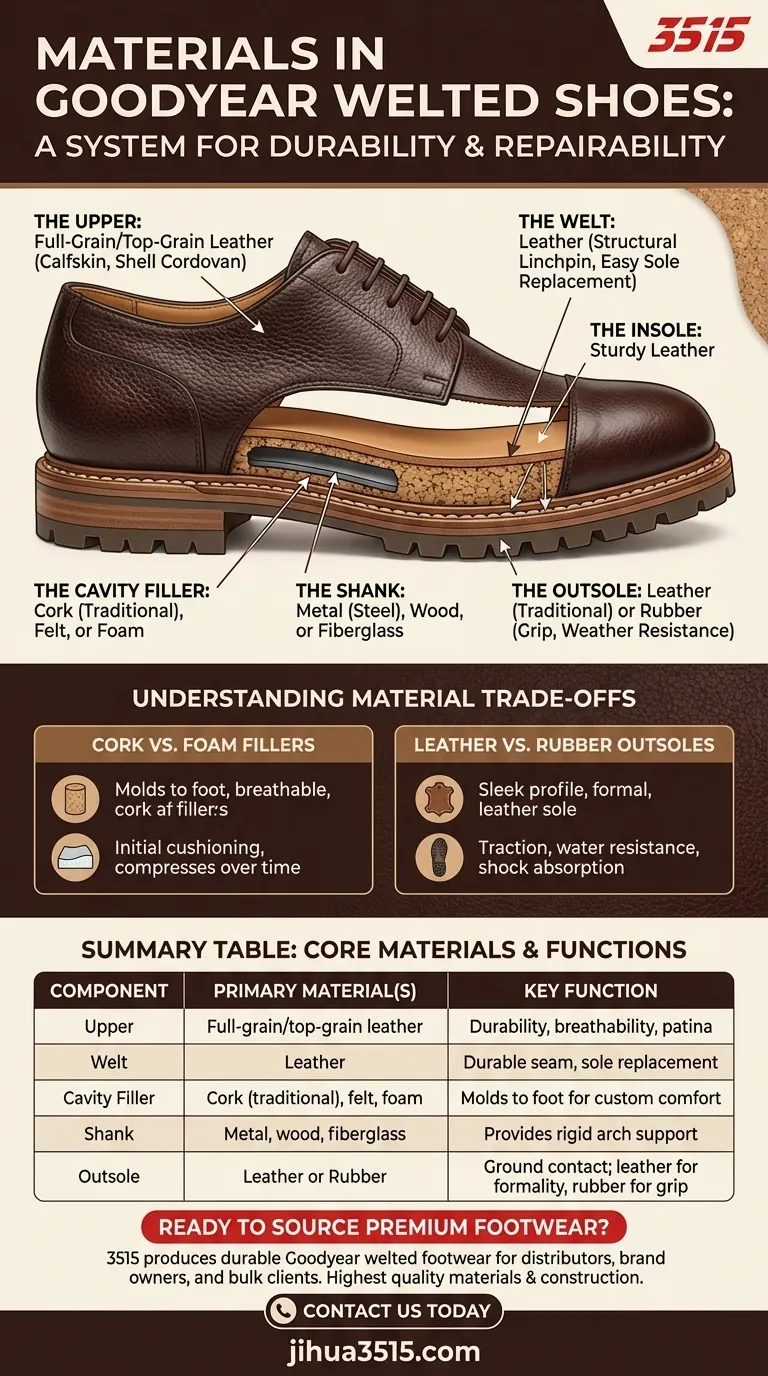

The Anatomy of a Goodyear Welted Shoe

To understand why certain materials are used, it's essential to look at the role each component plays in the shoe's structure and function.

The Upper: The Face of the Shoe

The upper is the most visible part of the shoe and is almost always made from a high-grade leather.

Full-grain or top-grain leather is the standard choice due to its exceptional durability, breathability, and ability to develop a rich patina with age. Common types include versatile calf leather and the famously resilient shell Cordovan.

The Welt: The Structural Linchpin

The welt is the defining feature of this construction method. It is a narrow strip of material, traditionally leather, that is stitched to both the upper and the insole.

The outsole is then stitched directly to the welt. This creates a highly durable, water-resistant seam and, most importantly, allows the outsole to be replaced multiple times without disturbing the upper.

The Cavity Filler: The Foundation of Comfort

Between the insole and the outsole, a cavity is created. This space is filled with a lightweight, moldable material.

The most common and traditional filler is cork. Over time, the heat and pressure from your foot cause the cork to compress and mold to its unique shape, creating a custom-like footbed. Felt is another traditional option, while some modern makers may use foam.

The Shank: The Hidden Support

Embedded between the insole and outsole is a rigid piece of material called a shank.

This is typically made of metal (such as steel), wood, or fiberglass. Its purpose is to provide structural support to the arch of the foot and prevent the shoe from flexing in the middle.

The Insole and Outsole: The Contact Layers

The insole forms the direct bed of the shoe and is a critical structural component, often made of thick, sturdy leather.

The outsole is the part that contacts the ground. While durable leather soles are traditional for formal footwear, many Goodyear welted boots and shoes now use rubber or composite soles for superior grip and weather resistance.

Understanding the Material Trade-offs

The choice of traditional materials comes with distinct advantages and disadvantages compared to modern alternatives.

Cork vs. Foam Fillers

Cork is prized for its ability to mold perfectly to your foot, providing customized support and excellent breathability.

Modern foam fillers can offer more initial "out-of-the-box" cushioning. However, foam tends to compress and break down over time, losing its supportive qualities and undermining the long-term benefit of the construction.

Leather vs. Rubber Outsoles

Leather outsoles are the classic choice, offering a sleek profile and high breathability, making them ideal for formal or office wear.

Rubber outsoles provide significantly better traction, water resistance, and shock absorption. They are the practical choice for shoes that will be worn frequently on city streets or in inclement weather.

The Cost of Quality

The materials inherent to this construction—full-grain leathers, cork, and the labor-intensive process itself—directly contribute to a higher price point. Materials like shell Cordovan can elevate the cost substantially but offer unparalleled durability and a unique finish.

Making the Right Choice for Your Goal

Your intended use for the shoe should guide your material preferences.

- If your primary focus is classic formality and maximum longevity: Prioritize shoes with full-grain calfskin uppers, a traditional leather outsole, and a cork footbed.

- If your primary focus is all-weather durability and daily comfort: Look for models that pair quality leather uppers with a durable rubber sole for better grip and cushioning.

- If your primary focus is a unique, long-lasting investment: Explore options made from specialty materials like shell Cordovan, but be prepared for a higher cost and specific care routine.

Understanding these core materials empowers you to look beyond the brand and evaluate the fundamental quality of any Goodyear welted shoe.

Summary Table:

| Component | Primary Material(s) | Key Function |

|---|---|---|

| Upper | Full-grain/top-grain leather (e.g., calfskin, shell Cordovan) | Durability, breathability, and patina development |

| Welt | Leather | Creates a durable, water-resistant seam for easy sole replacement |

| Cavity Filler | Cork (traditional), felt, or foam | Molds to the foot for custom comfort and support |

| Shank | Metal (e.g., steel), wood, or fiberglass | Provides rigid arch support |

| Outsole | Leather (traditional) or Rubber | Ground contact; leather for formality, rubber for grip |

Ready to Source Premium Goodyear Welted Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of Goodyear welted shoes and boots, ensuring the highest quality materials and construction for your customers.

Contact us today to discuss your production needs and leverage our expertise in creating long-lasting, repairable footwear.

Visual Guide

Related Products

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

People Also Ask

- How can crocodile-inspired leather dress shoes make a statement at formal events? Command Attention with Bold Style

- How can one identify authentic leather footwear? A Guide to Spotting Genuine vs. Fake

- Are sneakers acceptable in a business casual workplace? How to Choose the Right Style

- How does high-performance professional footwear serve as an ergonomic intervention to reduce physiological fatigue in high-intensity work environments? Boost Performance & Safety!

- What should consumers look for to avoid misleading claims about leather quality? A Guide to Identifying Genuine Quality