At its core, composite safety footwear is engineered from non-metallic materials designed to replace traditional steel components. The protective toe cap is typically made from a combination of carbon fiber, Kevlar® aramid fiber, fiberglass, and specialized plastics, while the rest of the shoe uses advanced polymers and textiles for the sole and upper.

The key insight is that modern safety footwear is a system of specialized materials. Each component—from the non-metallic toe cap to the rubber or polyurethane sole—is deliberately chosen to provide targeted protection, reduce weight, and resist specific workplace hazards without relying on metal.

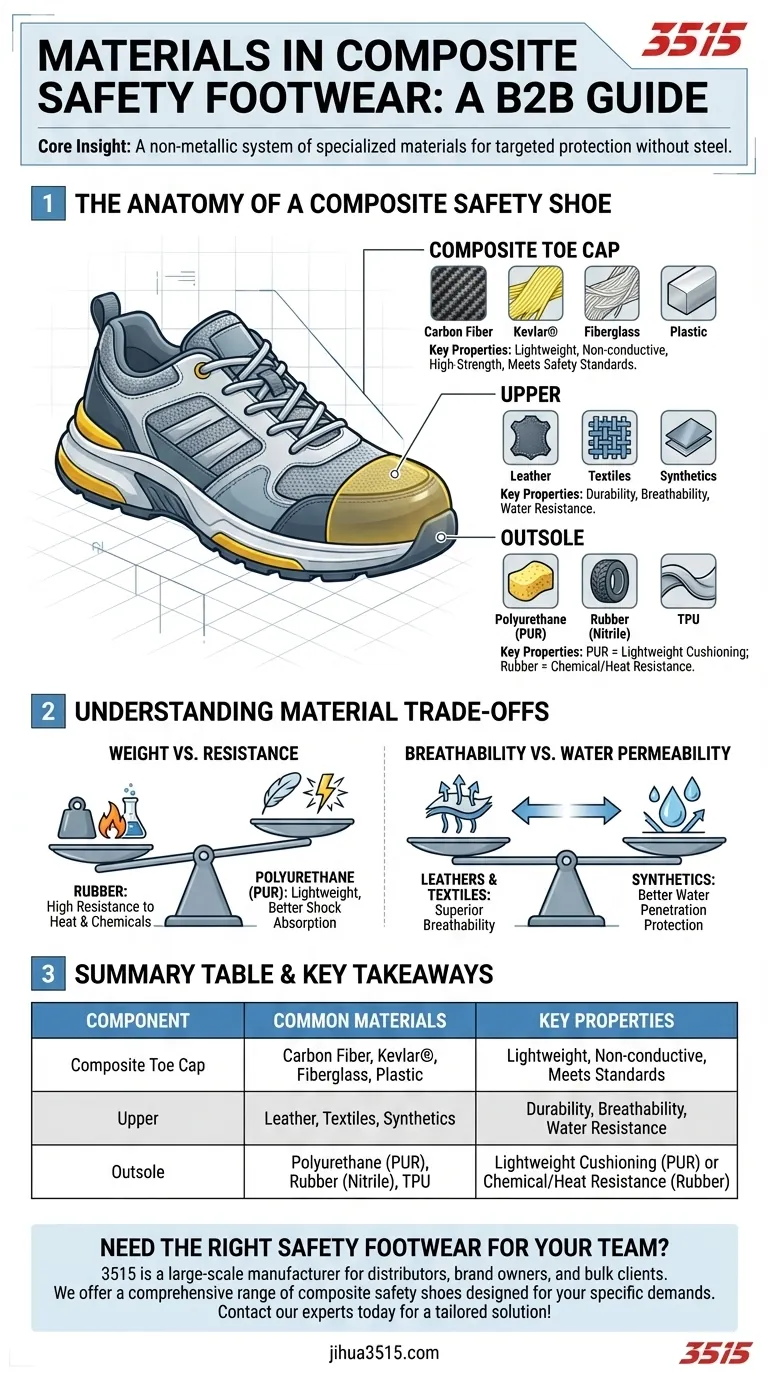

The Anatomy of a Composite Safety Shoe

A safety shoe is far more than just its protective toe cap. To understand the materials, we must look at the distinct components that work together to provide comprehensive safety and comfort.

The Composite Toe Cap: Protection Without Weight

The defining feature of this footwear is the toe cap. It's made from layers of high-strength, non-metallic materials to achieve its protective qualities.

The most common materials include carbon fiber, Kevlar®, fiberglass, and plastic. These are layered and molded to create a cap that meets strict safety standards while eliminating the bulk and weight associated with steel.

This non-metallic construction also means the toe cap won't conduct electricity, heat, or cold, adding a layer of comfort and safety in certain environments.

The Upper: The First Line of Defense and Comfort

The upper part of the shoe protects the rest of the foot and provides structural support. The material choice here is critical for both durability and user comfort.

Common materials include various types of leather (smooth, nubuck, split), textiles, and other synthetic materials. The selection is based on characteristics like breathability, water resistance, durability, and cleanability.

The Outsole: Your Connection to the Ground

The outsole is the part that makes direct contact with the ground, and its material composition dictates its performance in different conditions.

Materials are chosen for specific resistances and properties. The most common are Polyurethane (PUR), Thermoplastic Polyurethane (TPU), and rubber (often nitrile rubber).

PUR is valued for being lightweight and providing excellent shock absorption. Rubber, on the other hand, offers superior resistance to high heat and harsh chemicals, making it ideal for more demanding industrial environments.

Understanding the Material Trade-offs

Choosing the right safety footwear involves balancing competing material benefits. There is no single "best" material, only the best material for a specific application.

Heat and Chemical Resistance vs. Weight

There is a direct trade-off between the outsole's weight and its resilience.

Rubber outsoles provide the highest level of resistance to heat, acids, and alkalis. However, they are typically heavier than their polyurethane counterparts.

Polyurethane (PUR) outsoles significantly reduce the shoe's overall weight and offer better shock absorption, but they provide less resistance to extreme heat and chemicals.

Breathability vs. Water Permeability

The materials used for the shoe's upper dictate how it handles moisture, both from the environment and from your foot.

Leathers and textiles are often chosen for their superior breathability, which is crucial for comfort during long shifts.

Conversely, certain synthetic materials and coatings offer better protection against water penetration, which may come at the cost of reduced airflow.

Making the Right Choice for Your Goal

Your specific work environment and daily tasks should dictate your material priorities.

- If your primary focus is working with chemicals or high heat: Prioritize footwear with a nitrile rubber outsole for its superior chemical and thermal resistance.

- If your primary focus is reducing fatigue from long hours of walking or standing: Look for designs with lighter polyurethane (PUR) outsoles and a carbon fiber or Kevlar composite toe.

- If your primary focus is working near live electrical circuits: A non-metallic composite toe is a mandatory feature, as it does not conduct electricity.

Ultimately, understanding the specific materials in your safety footwear empowers you to select the right tool that ensures both your safety and your comfort on the job.

Summary Table:

| Component | Common Materials | Key Properties |

|---|---|---|

| Composite Toe Cap | Carbon Fiber, Kevlar®, Fiberglass, Plastic | Lightweight, non-conductive, meets safety standards |

| Upper | Leather, Textiles, Synthetics | Durability, breathability, water resistance |

| Outsole | Polyurethane (PUR), Rubber (Nitrile), TPU | Lightweight cushioning (PUR) or chemical/heat resistance (Rubber) |

Need the right safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of composite safety shoes and boots, designed to meet the specific demands of your work environment.

Let us help you equip your workforce with the perfect balance of protection, comfort, and durability. Contact our experts today for a tailored solution!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How long can you wear safety boots? The Lifespan is Determined by Wear, Not Time

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are OSHA approved shoes? Understanding the Correct Standards for Workplace Safety

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management