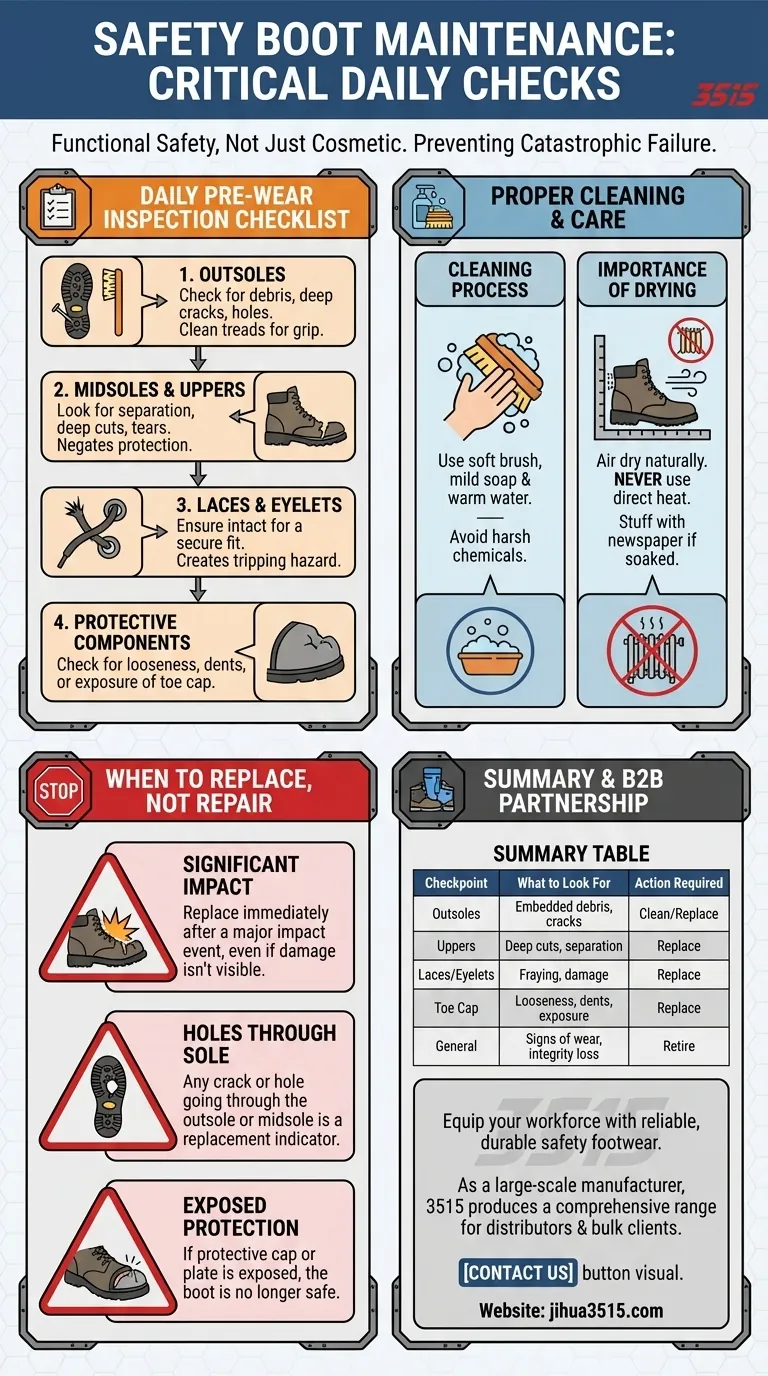

The most critical maintenance checks for safety boots involve a daily inspection of the soles and uppers. Before each use, you must check the outsoles for any embedded metal shards, stones, or other debris, and look for any signs of cracks, holes, or separation from the upper boot. You should also ensure the laces are in good condition and the overall structure is free from deep cuts or damage that could compromise its protective features.

The core purpose of safety boot maintenance is not cosmetic. It is a functional safety procedure designed to ensure the boot's protective integrity has not been compromised, preventing catastrophic failure when you need it most.

Why Proactive Maintenance is Non-Negotiable

A safety boot is a piece of personal protective equipment (PPE). Its ability to protect you from impact, compression, punctures, and electrical hazards degrades with wear and tear.

Regular maintenance is the only way to identify when a boot is no longer capable of providing its specified level of protection. Relying on a damaged boot is a significant and avoidable workplace risk.

A Systematic Inspection Checklist

Adopting a consistent routine is the best way to ensure nothing is missed. Perform these checks before putting your boots on for the day.

Inspect the Outsoles

The outsole is your primary point of contact with the ground and is critical for both grip and puncture resistance. Look for any metal shards, screws, or sharp stones that may have become embedded.

Also, check for deep cracks or holes that could allow liquids or sharp objects to penetrate through to your foot. Use a soft bristle brush to clear the treads of mud or debris to maintain optimal grip.

Examine the Midsoles and Uppers

Check the area where the sole platform connects to the upper part of the boot. Look for any signs of separation or delamination, which can compromise waterproofing and structural support.

Inspect the leather or synthetic upper for any deep cuts, tears, or punctures. Minor scuffs are cosmetic, but a breach in the material can negate its protective qualities.

Check Laces and Eyelets

Frayed or damaged laces can snap, creating a tripping hazard and preventing a secure fit. A boot that is not laced tightly cannot provide proper ankle support or prevent debris from entering.

Ensure the eyelets are intact and not bent or broken, which could damage the laces or prevent proper tightening.

Assess Protective Components

If your boots have a steel or composite toe cap, press firmly on it to check for any looseness. Visually inspect for any major dents or if the cap has become exposed through the outer material, which are clear signs the boot must be replaced.

Proper Cleaning and Care

Proper cleaning is a foundational part of maintenance that extends the life of your boots and makes inspections easier.

The Cleaning Process

Remove dirt and debris using a soft bristle brush. For deeper cleaning, use a simple solution of mild soap and warm water, avoiding harsh chemical detergents that can degrade leather and adhesives.

The Importance of Proper Drying

Never dry your boots with a direct heat source like a radiator or fire. This can cause the leather to crack and adhesives to fail.

Allow them to dry naturally at room temperature. If they are soaked, stuffing them with newspaper can help absorb excess moisture and speed up the process.

When to Replace, Not Repair

Maintenance can preserve a boot, but it cannot fix one that is fundamentally compromised. Knowing when to retire a pair of boots is a critical safety judgment.

Clear Signs for Replacement

A boot must be replaced immediately if it has experienced a significant impact or compression event, even if there is no visible damage to the toe cap.

Any hole or crack that goes through the outsole or midsole is a clear indicator for replacement. Similarly, if the protective toe cap or puncture-resistant plate becomes exposed, the boot is no longer safe.

Making the Right Choice for Your Goal

Your daily routine should reflect your primary objective for wearing safety footwear.

- If your primary focus is maximum safety and compliance: Your non-negotiable step is a brief, daily pre-wear inspection of the soles, uppers, and protective toe.

- If your primary focus is extending boot lifespan and value: Your key habit is regular cleaning with mild soap and always allowing the boots to dry naturally away from direct heat.

Ultimately, treating your safety boots with the same care as any other critical tool is the best way to ensure they protect you day after day.

Summary Table:

| Checkpoint | What to Look For | Action Required |

|---|---|---|

| Outsoles | Embedded debris, cracks, holes | Clean treads, replace if damaged |

| Uppers | Deep cuts, tears, separation | Replace if protective layer is breached |

| Laces & Eyelets | Fraying, damage, breakage | Replace to ensure secure fit |

| Toe Cap | Looseness, dents, exposure | Replace immediately if compromised |

| General Structure | Signs of wear, loss of integrity | Retire boots if safety is compromised |

Ensure your workforce is equipped with reliable, durable safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots and work footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed to meet the highest standards of protection and durability. Contact us today to discuss your specific needs and benefit from our expertise in safety footwear manufacturing.

Visual Guide

Related Products

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

People Also Ask

- How does toe box design differ between men's and women's work boots? Fit for a Woman's Foot Anatomy

- Why is maintenance important for work boots? Protect Your Investment and Safety

- What organization sets national standards for workplace safety in the U.S.? OSHA's Role Explained

- What are the four key aspects to consider when choosing high-quality safety footwear? Ensure True Anatomical Fit & Protection

- What are the potential consequences of wearing improperly designed work boots? Avoid Injury & Boost Safety