I see my role as a trusted advisor, aiming to provide a clear and insightful response. My goal isn't just to list facts but to explain the significance of these features for an audience of knowledgeable professionals.

1. Understanding the Core Question:

My first step is to unpack the question. I know the user isn't just after a simple description; they're interested in the why behind the construction of western boot heels and heel counters. They want to understand what makes them special—durability, repairability, and overall value.

2. Utilizing the Provided References (Critically):

The references offer the basic facts. Western boots use "full leather stacked heels and molded leather heel counters," unlike many that use "a mix of particle board and leather." This points directly to a commitment to quality and longevity. But I need to go deeper.

3. Developing a Focused and Informative Structure:

I'm building a concise structure to address the surface and deep needs. It'll open with a direct answer and a "Core Takeaway" blockquote summarizing the key benefit: longevity. The main body will detail the construction and contrast it with less durable alternatives. I'll highlight the trade-offs (like cost and break-in) honestly. Finally, I'll offer actionable advice: what to look for based on a customer's specific needs.

4. Focusing on Clarity and Authority:

I'm aiming for objective authority. My language will be clear and direct, using analogies to explain complex concepts. I'll utilize bolding, headers, and bullet points for easy scanning. The focus is on conveying my expert understanding in a simple and scannable format.

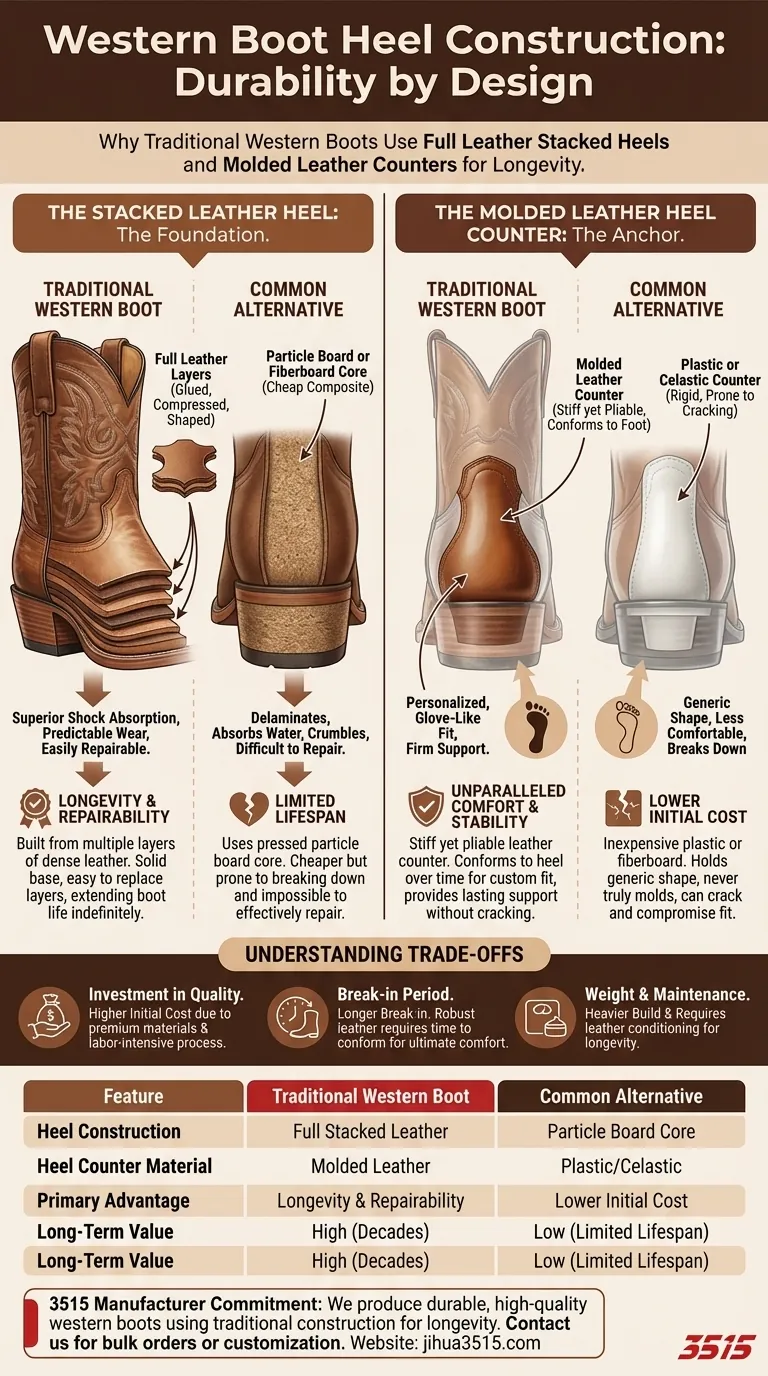

The outcome will be a detailed and informative analysis that empowers the user to make informed choices about western boots. At the core of a western boot's unique character is a foundational commitment to traditional, durable materials. Unlike many modern boots, their heels and heel counters are crafted from full, stacked leather and molded leather, respectively. This construction avoids cost-cutting composites like particle board, prioritizing a structure built for longevity and repair.

The use of all-leather heels and counters is not merely a stylistic choice; it is a fundamental engineering decision. This method prioritizes long-term durability, repairability, and a custom-like fit over the lower costs and disposability of modern composite materials.

The Foundation: The Stacked Leather Heel

A boot's heel is its primary point of contact with the ground, absorbing immense stress with every step. The material used here dictates the boot's lifespan and serviceability.

What "Stacked Leather" Means

A stacked leather heel is built from multiple layers of dense, real leather that are glued, compressed, and shaped. This creates a solid, resilient base that is integral to the boot's structure.

The Advantage of All-Leather

This method provides superior shock absorption and wears down predictably and evenly over time. Crucially, a skilled cobbler can easily replace individual layers or the entire heel cap, extending the boot's life indefinitely.

The Common Alternative: Particle Board

Many contemporary boots use a core of pressed particle board or fiberboard, often wrapped in a thin leather or synthetic veneer. While cheaper to produce, these materials can delaminate, absorb water, and crumble, making effective, long-term repairs nearly impossible.

The Anchor: The Molded Leather Heel Counter

The heel counter is the unseen hero of a boot's structure. It is the internal component that cups your heel, providing critical support and preventing the boot from collapsing.

The Role of a Heel Counter

This component locks your heel in place, providing stability and maintaining the boot's shape. A well-made counter is essential for proper fit, comfort, and preventing excessive wear on the boot's upper.

Why Molded Leather is Superior

A molded leather heel counter is stiff yet pliable. Over time, it slowly conforms to the unique shape of your heel, creating a personalized, glove-like fit. It provides firm, lasting support that will not crack or break down over decades of use.

The Contrast: Plastic and Fiberboard

The most common alternatives are thermoplastic or cellulose fiberboard (celastic) counters. These are inexpensive and hold a generic shape, but they are rigid and prone to cracking over time. They never truly mold to the wearer's foot, compromising long-term fit and support.

Understanding the Trade-offs

The commitment to all-leather construction is not without its considerations. Understanding these trade-offs is key to appreciating the value proposition of a traditionally made western boot.

The Investment in Quality

The primary trade-off is cost. Full-grain leather is a more expensive raw material, and the process of stacking a heel or molding a counter is far more labor-intensive than using pre-fabricated composite parts. This is directly reflected in the boot's higher initial price.

The Break-in Period

A robust leather heel counter is significantly stiffer out of the box than a plastic one. This can mean a longer and more demanding break-in period is required before the boot achieves its ultimate, comfortable fit.

Weight and Maintenance

Solid leather construction is generally heavier than boots that rely on synthetic or composite materials. Furthermore, to ensure its longevity, the leather in the heel stack requires occasional conditioning, just like the boot's upper, to prevent it from drying out.

Making the Right Choice for Your Goal

Your decision should be guided by what you value most in a piece of footwear.

- If your primary focus is maximum durability and future repairability: You must choose a boot built with a full stacked leather heel and a true molded leather heel counter.

- If your primary focus is a lower initial purchase price for casual use: A boot with composite heel materials may be adequate, but you must accept its fundamentally limited lifespan.

- If your primary focus is achieving a personalized, supportive fit: The investment in a leather counter that molds to your foot will provide unparalleled comfort and stability over the long term.

Understanding these foundational components empowers you to look beyond simple aesthetics and invest in genuine, lasting craftsmanship.

Summary Table:

| Feature | Traditional Western Boot | Common Alternative |

|---|---|---|

| Heel Construction | Full Stacked Leather | Particle Board Core |

| Heel Counter Material | Molded Leather | Plastic/Celastic |

| Primary Advantage | Longevity & Repairability | Lower Initial Cost |

| Long-Term Value | High (Decades of Use) | Low (Limited Lifespan) |

As a large-scale manufacturer, 3515 produces durable, high-quality western boots for distributors, brand owners, and bulk clients. Our commitment to traditional construction—using stacked leather heels and molded leather heel counters—ensures your customers receive footwear built to last. We offer comprehensive production capabilities for all types of boots, guaranteeing superior value and long-term satisfaction. Ready to stock or customize boots with genuine, lasting craftsmanship? Contact our team today to discuss your project.

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

People Also Ask

- What is the advantage of using a nine-axis inertial sensor over a six-axis? Unlock Precise Foot Motion Tracking

- How does synchronization analysis software integrate data for footwear design? Master Multi-Sensor Fusion for R&D

- What is the specific value of a flexible in-shoe pressure monitoring system? Real-Time Data for Footwear Validation

- What types of foot problems are associated with repetitive motion or prolonged standing? Protect Your Foundation

- Why is efficient equipment scheduling critical for mixed footwear production? Maximize Asset Turnover & Efficiency

- How does the 'Remove and Measure' method work for shoelace length? Get a Perfect Fit Every Time

- What role does a high-frame-rate 3D motion capture system play in gait analysis? Precision Data for Footwear Testing

- How does the post-processing polishing stage affect the quality of a manufactured orthopedic insole? Ensure Patient Safety & Optimal Fit