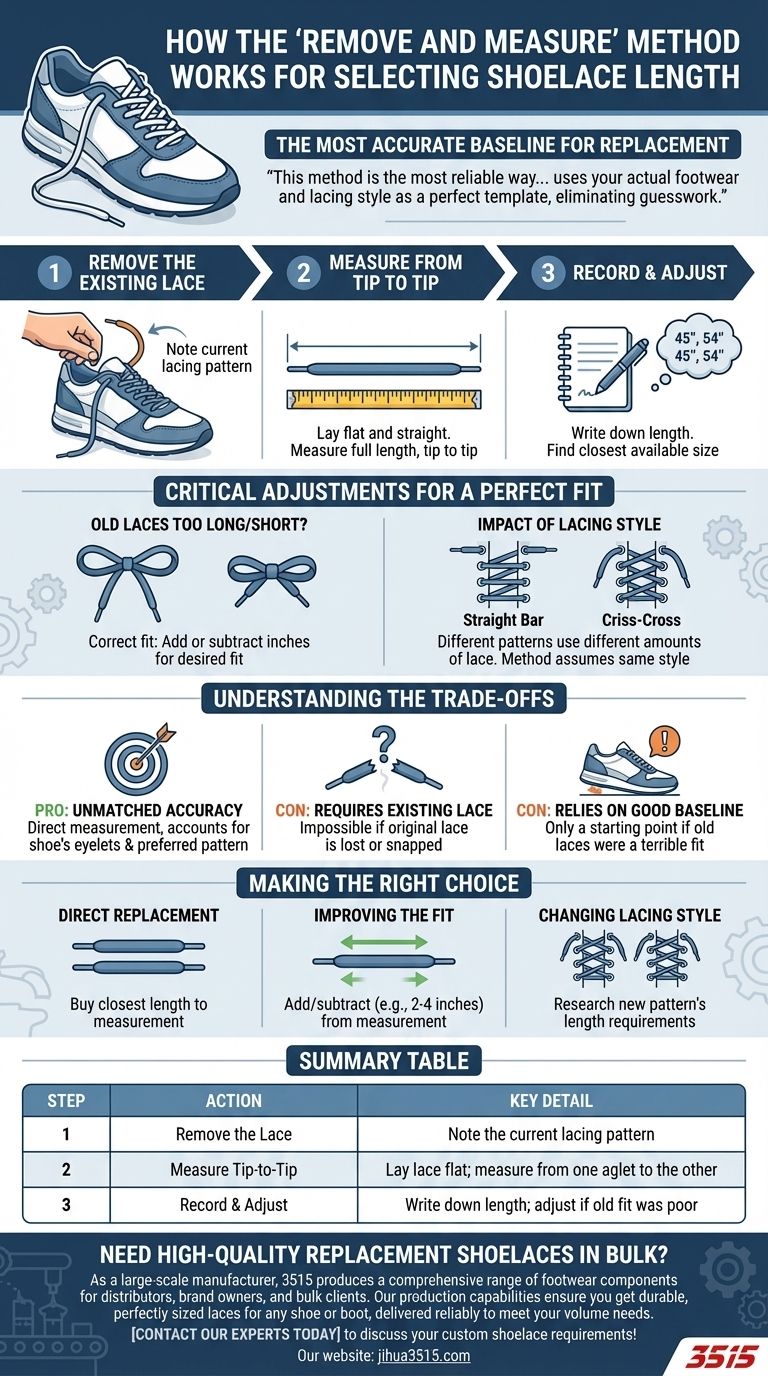

The 'Remove and Measure' method is a straightforward technique for finding the correct shoelace length by taking the existing lace out of your shoe and measuring it from one plastic tip (aglet) to the other. This direct measurement provides the most accurate baseline for purchasing a replacement.

This method is the most reliable way to replace shoelaces, as it uses your actual footwear and lacing style as a perfect template, eliminating guesswork.

How the Method Works in Practice

The process is simple but requires attention to a few key details to ensure you purchase the correct replacement length.

Step 1: Remove the Existing Lace

Carefully unlace the shoe, taking note of the lacing pattern you currently use. Pull the entire lace out of the eyelets.

Step 2: Measure from Tip to Tip

Lay the old shoelace flat and straight on a surface. Use a tape measure or ruler to measure the full length, from the very end of one plastic tip to the end of the other.

Step 3: Record Your Measurement

Write down the length. Shoelaces are typically sold in standardized lengths (e.g., 45 inches, 54 inches), so you will use this measurement to find the closest available size.

Critical Adjustments for a Perfect Fit

A simple measurement is often not enough. Your satisfaction with the old laces determines whether you need to make adjustments to this number.

If the Old Laces Were Too Long or Short

If you felt the loops of your bow were excessively long or you struggled to tie them, now is the time to correct it. Add or subtract a few inches from your measurement to achieve your desired fit.

The Impact of Lacing Style

Different lacing patterns use different amounts of lace. A "straight bar" lacing uses less lace than a traditional "criss-cross" pattern. The 'Remove and Measure' method assumes you will use the same lacing style for the new laces.

Understanding the Trade-offs

While highly effective, this method has specific strengths and weaknesses you should be aware of.

Pro: Unmatched Accuracy

Measuring the lace that was already in the shoe is the most direct and accurate way to find a replacement. It accounts for your specific shoe's eyelet spacing and your preferred lacing pattern.

Con: Requires an Existing Lace

The primary drawback is that this method is impossible if the original lace is lost or has snapped into multiple pieces.

Con: Relies on a Good Baseline

If your original laces were a terrible fit (either far too long or short), this method only gives you a starting point. You still need to estimate how much length to add or subtract.

Making the Right Choice for Your Goal

Use your measurement and experience with the old laces to guide your purchase.

- If your primary focus is a direct replacement: Buy the closest available length to your exact measurement for an identical fit.

- If your primary focus is improving the fit: Measure your old lace and then intentionally add or subtract length (e.g., 2-4 inches) to get the bow size you prefer.

- If your primary focus is changing your lacing style: Use your measurement as a starting point, but research whether your new, desired pattern requires a longer or shorter lace.

Ultimately, using your old lace as a physical guide is the surest path to getting the right fit the first time.

Summary Table:

| Step | Action | Key Detail |

|---|---|---|

| 1 | Remove the Lace | Note the current lacing pattern. |

| 2 | Measure Tip-to-Tip | Lay lace flat; measure from one aglet to the other. |

| 3 | Record & Adjust | Write down length; adjust if old fit was poor. |

Need high-quality replacement shoelaces in bulk?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear components for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, perfectly sized laces for any shoe or boot, delivered reliably to meet your volume needs.

Contact our experts today to discuss your custom shoelace requirements!

Visual Guide

Related Products

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Wholesale Durable & Breathable Training Shoes for Custom Brands

People Also Ask

- Why are specific physical movements required for data synchronization? Master Timing for IMUs & Pressure Insoles

- What parts of the shoe are assessed using a sandpaper tip tool? Uncover the 3 Key Durability Test Zones

- Is it safe to ride without motorcycle boots? The Critical Footwear Safety Gap Every Rider Must Know

- How are professional-grade wireless motion trackers utilized in the gait analysis of RDW studies? Master Data Accuracy

- What factors should be considered when choosing a waterproofing treatment? Select the Right Protection for Your Footwear

- How do circular economy-oriented manufacturing systems optimize footwear lifecycles? Boost Efficiency and Sustainability

- What is the role of wearable foot trackers in footwear and flooring experiments? Master Visual-Tactile Synchronization

- How should footwear made of leather, PU or PVC be cleaned? Master the Universal Cleaning Method