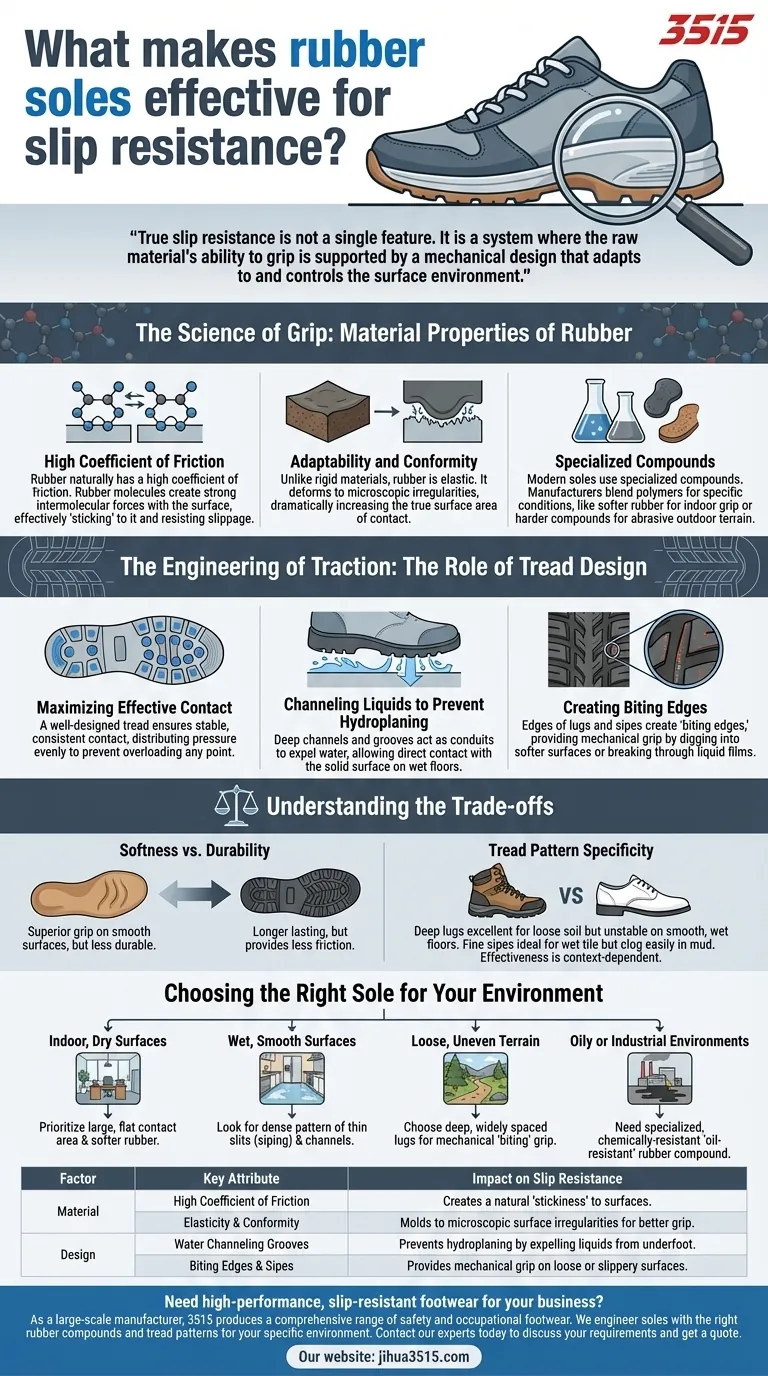

At its core, the effectiveness of a rubber sole comes from a powerful combination of its inherent material properties and its engineered physical design. The rubber itself creates a high degree of friction, while the tread pattern is designed to maintain that grip by maximizing contact and clearing away contaminants like water.

True slip resistance is not a single feature. It is a system where the raw material's ability to grip is supported by a mechanical design that adapts to and controls the surface environment.

The Science of Grip: Material Properties of Rubber

The foundation of a sole's performance begins with the chemical and physical nature of the rubber itself. This material is uniquely suited for creating high levels of friction.

High Coefficient of Friction

Rubber naturally has a high coefficient of friction. This is a scientific measure of how much force is required to slide one surface over another.

Simply put, rubber molecules create strong intermolecular forces with the molecules of the walking surface, effectively "sticking" to it and resisting slippage.

Adaptability and Conformity

Unlike rigid materials, rubber is elastic and pliable. On a microscopic level, no surface is perfectly flat.

Rubber deforms slightly under pressure, allowing it to mold to these tiny irregularities. This dramatically increases the true surface area of contact, giving the sole more to grip onto.

Specialized Compounds

Modern soles often use specialized rubber compounds engineered for specific tasks.

Manufacturers can blend different polymers and additives to optimize for certain conditions, such as creating softer rubber for maximum indoor grip or a harder, more durable compound for abrasive outdoor terrain.

The Engineering of Traction: The Role of Tread Design

If the rubber material provides the potential for grip, the tread design is what unlocks that potential in the real world. A tread pattern is a functional piece of engineering, not just a style choice.

Maximizing Effective Contact

A well-designed tread ensures that the rubber material makes stable and consistent contact with the ground.

Grooves and lugs are patterned to distribute pressure evenly across the sole, preventing any single point from becoming overloaded and losing traction.

Channeling Liquids to Prevent Hydroplaning

On wet surfaces, the greatest danger is hydroplaning—when a thin layer of water separates the sole from the ground, causing a near-total loss of friction.

The deep channels and grooves in a tread pattern act as conduits. They are specifically designed to expel water from underneath the sole, allowing the rubber to make direct contact with the solid surface.

Creating Biting Edges

The edges of the lugs and sipes (small slits) in a tread pattern create countless "biting edges."

These sharp, angled surfaces provide mechanical grip by digging into softer surfaces like dirt or snow and creating points of high pressure on smoother surfaces to break through liquid films.

Understanding the Trade-offs

No single sole design is perfect for every situation. Understanding the inherent compromises is key to appreciating why different footwear exists for different purposes.

Softness vs. Durability

Softer rubber compounds offer superior grip, especially on smooth, dry surfaces, because they conform better to microscopic imperfections. However, this pliability comes at the cost of durability, as the material wears away much faster.

Conversely, harder rubber lasts longer but provides less friction, making it a compromise between longevity and peak performance.

Tread Pattern Specificity

A deep, aggressive lug pattern designed for hiking is excellent on loose soil but can be a liability on a smooth, wet floor. The reduced surface area of the lug tips can make the shoe less stable.

A pattern with many fine sipes is ideal for wet tile but would quickly clog with mud and become useless outdoors. The effectiveness of a tread is entirely context-dependent.

Choosing the Right Sole for Your Environment

Your choice should be dictated by the primary challenge of your environment. Consider the surface, the likely contaminants, and the durability you require.

- If your primary focus is indoor, dry surfaces: Prioritize soles with a large, flat contact area and softer rubber for maximum friction.

- If your primary focus is wet, smooth surfaces (e.g., kitchens, boats): Look for a dense pattern of thin slits (siping) and channels designed to aggressively expel water.

- If your primary focus is loose, uneven terrain (e.g., hiking trails): Choose deep, widely spaced lugs that provide mechanical "biting" grip and shed mud easily.

- If your primary focus is oily or industrial environments: You need a specialized, chemically-resistant rubber compound certified as "oil-resistant" to prevent the material from degrading and losing its grip.

Ultimately, understanding these principles empowers you to see a shoe's sole not as a feature, but as a purpose-built tool for a specific job.

Summary Table:

| Factor | Key Attribute | Impact on Slip Resistance |

|---|---|---|

| Material | High Coefficient of Friction | Creates a natural 'stickiness' to surfaces. |

| Material | Elasticity & Conformity | Molds to microscopic surface irregularities for better grip. |

| Design | Water Channeling Grooves | Prevents hydroplaning by expelling liquids from underfoot. |

| Design | Biting Edges & Sipes | Provides mechanical grip on loose or slippery surfaces. |

Need high-performance, slip-resistant footwear for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety and occupational footwear for distributors, brand owners, and bulk clients. We engineer soles with the right rubber compounds and tread patterns for your specific environment—from industrial kitchens to construction sites.

Contact our experts today to discuss your requirements and get a quote. We'll help you equip your team with the right grip for the job.

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Wholesale Leather Ankle Boots with Lug Soles for Custom Brand Manufacturing

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained

- What types of rubber are typically employed in non-slip footwear soles? Your Guide to Maximum Grip and Safety

- What material should the sole of a non-slip shoe be made of? The Key to Maximum Traction

- How can footwear sole technology be upgraded to prevent entrapment risks? Engineering Safe, Anti-Snap Designs

- What role do slip-resistant rubber materials play in safety shoes? Ensuring Grip and Stability in Hazardous Workplaces