The exceptional grip of natural rubber stems directly from its unique molecular structure. Unlike more rigid synthetic materials, natural rubber is composed of long, flexible, and entangled polymer chains (cis-1,4-polyisoprene) that can easily deform and mold themselves to the microscopic imperfections of any surface, maximizing the physical contact area and, therefore, the resulting friction.

The core reason for natural rubber's superior grip is not its softness, but its molecular ability to achieve near-perfect contact with a surface. This intimate conformance generates high levels of friction by maximizing the forces of adhesion at a microscopic level.

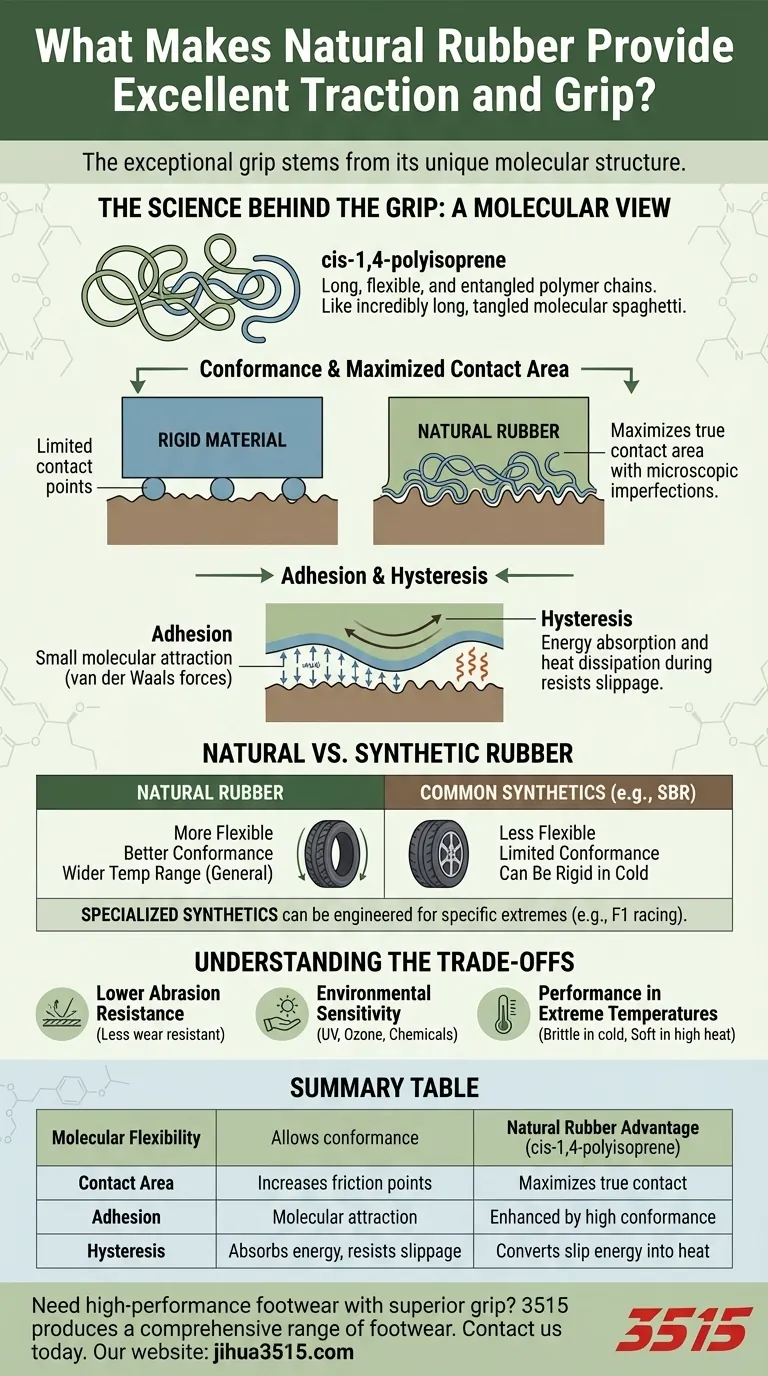

The Science Behind the Grip: A Molecular View

To truly understand why natural rubber excels, we must look at its behavior at the molecular scale. The properties that make it ideal for traction are a direct result of its chemical composition and physical arrangement.

The cis-1,4-polyisoprene Polymer

Natural rubber is primarily a polymer named cis-1,4-polyisoprene. Imagine this as incredibly long, tangled strands of molecular spaghetti.

These chains are naturally coiled and disordered. This inherent lack of a rigid structure is precisely what gives the material its remarkable elasticity and flexibility.

Conformance and Maximized Contact Area

Grip is fundamentally a function of friction, and friction is heavily dependent on the true contact area between two surfaces.

Because the polymer chains in natural rubber are so flexible, the material readily deforms under pressure. It essentially "flows" into the microscopic peaks and valleys of a surface, from smooth pavement to rough rock.

This perfect conformance dramatically increases the actual surface area in contact, creating far more points for frictional forces to take hold compared to a stiffer material that might only touch the highest peaks.

Adhesion and Hysteresis

Beyond simple contact, two other phenomena are at play. Adhesion refers to the weak molecular attraction (van der Waals forces) that occurs between the rubber and the surface. More contact area means more adhesion.

More importantly, hysteresis is the energy lost as heat when the rubber deforms and then returns to its shape. This energy absorption dampens vibrations and resists slippage, effectively converting some of the energy that would cause a slip into heat. This is a critical component of grip, especially on wet or uneven surfaces.

Natural vs. Synthetic Rubber

While "synthetic rubber" is a broad category, we can draw some general comparisons that highlight why the natural variant often has an edge in pure traction.

Why Natural Rubber Often Excels

Many common synthetic rubbers, like Styrene-Butadiene Rubber (SBR) used in car tires, have molecular structures that are less flexible or more ordered than natural rubber.

This can limit their ability to conform perfectly to a surface, especially in colder conditions where they can become more rigid. The unique entangled structure of natural rubber gives it a performance advantage across a wider temperature range.

The Rise of Specialized Synthetics

It is crucial to note that materials science has evolved. Engineers can now design highly specialized synthetic rubbers that match or even exceed natural rubber for a specific application.

For example, a Formula 1 racing tire uses a synthetic compound engineered for extreme grip at very high temperatures—a condition where natural rubber would fail.

Understanding the Trade-offs

Choosing a material is always about balancing competing properties. The very characteristics that give natural rubber its fantastic grip also introduce key limitations.

Lower Abrasion Resistance

The same molecular flexibility that allows for high conformance can also make natural rubber less resistant to wear and tear. Harder, less-grippy synthetic compounds often last longer because they are more resistant to abrasion.

Environmental Sensitivity

Natural rubber is susceptible to degradation from exposure to UV light, ozone, and certain oils or solvents. Over time, these elements can break down the polymer chains, causing the rubber to become brittle and lose its desirable properties.

Performance in Extreme Temperatures

While it performs well across a broad range of temperatures, natural rubber can become stiff and brittle in extreme cold and can soften or degrade at very high temperatures. Engineered synthetics often provide a more stable and predictable performance envelope at these extremes.

Making the Right Choice for Your Application

The decision to use natural rubber or a synthetic alternative depends entirely on the primary goal of your product.

- If your primary focus is maximum grip on varied, everyday surfaces: Natural rubber's innate ability to conform makes it an excellent, often superior, choice for applications like hiking boot soles or all-weather bicycle tires.

- If your primary focus is durability and long-term wear resistance: A purpose-built synthetic rubber or a blend is often the better solution, trading a small amount of grip for a significant increase in lifespan.

- If your primary focus is resistance to harsh environments (chemicals, oil, UV): A specialized synthetic like nitrile, EPDM, or silicone is non-negotiable, as natural rubber would quickly fail.

By understanding the molecular basis of grip, you can select a material based on fundamental principles, ensuring your choice is perfectly aligned with your performance requirements.

Summary Table:

| Key Factor | Role in Grip | Natural Rubber Advantage |

|---|---|---|

| Molecular Flexibility | Allows material to conform to surface imperfections | Long, flexible polymer chains (cis-1,4-polyisoprene) |

| Contact Area | Increases points for friction | Maximizes true contact with microscopic surface details |

| Adhesion | Creates molecular attraction to the surface | Enhanced by high conformance and van der Waals forces |

| Hysteresis | Absorbs energy to resist slippage | Converts slip energy into heat, dampening vibrations |

Need high-performance footwear with superior grip?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, leveraging material science to deliver the perfect balance of traction, durability, and performance for your market.

Contact us today to discuss how we can manufacture the ideal footwear solution for your needs.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

People Also Ask

- What is vulcanized rubber and why is it used in products? The Key to Durable, Flexible Footwear

- What are rubber soled shoes? The Ultimate Guide to Durable, All-Weather Footwear

- What historical breakthrough in 1844 contributed to modern shoe sole manufacturing? The Vulcanization Revolution

- Why should we wear rubber soled shoes? Unlock Superior Safety and Durability

- Which type of sole is better for premium sneakers and why? The Definitive Guide to Rubber Outsoles