In short, durable safety boots are the product of combining high-grade materials with robust construction methods. It isn't a single feature, but the synergy of components like full-grain leather, reinforced stitching, and a resilient sole, all assembled through a meticulous manufacturing process designed to withstand harsh conditions.

True durability in a safety boot is not an accident. It is the direct result of intentional design choices, from the specific grade of leather used to the type of welt that joins the upper to the sole.

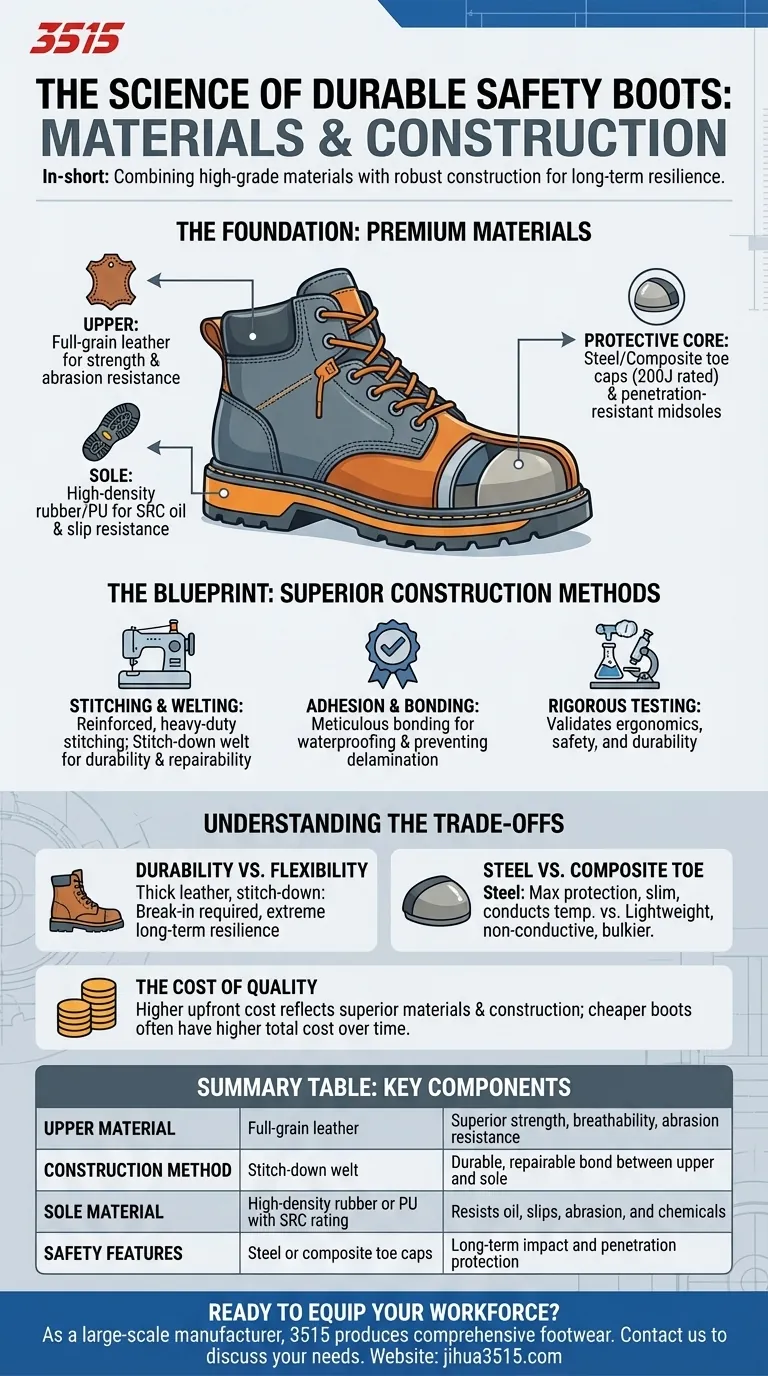

The Foundation: Premium Materials

A boot is only as strong as its weakest component. Durability begins with the careful selection of materials that are inherently tough, resilient, and suited for a demanding work environment.

The Upper: Beyond Standard Leather

The most visible part of the boot, the upper, takes the most direct abuse. Full-grain leather is the premium standard, known for its exceptional strength, breathability, and ability to endure scrapes and flexing without cracking.

The Sole: Your Connection to the Ground

The outsole must resist abrasion, chemicals, and punctures. Look for soles made from high-density rubber or polyurethane (PU) that are specifically rated for oil and slip resistance (SRC). This ensures both longevity and safety.

The Protective Core: Non-Negotiable Safety

Safety features must last the lifetime of the boot. Steel or composite toe caps rated for 200-joule impact and penetration-resistant midsoles are foundational. Their durability is a direct measure of the boot's ability to protect you long-term.

The Blueprint: Superior Construction Methods

How the premium materials are assembled is just as critical as the materials themselves. The construction method dictates the boot's structural integrity and its ability to resist separation and wear.

Stitching and Welting

Look for signs of superior craftsmanship, like reinforced, heavy-duty stitching at all stress points. A stitch-down welt (like a Goodyear welt) is a hallmark of a high-quality boot, as it physically sews the upper to the sole, creating a far more durable and often repairable bond than simple glue.

Adhesion and Bonding

For boots that rely on adhesives, the quality of the bonding process is paramount. Meticulous manufacturing ensures a perfect, lasting seal between components, which is critical for waterproofing and preventing delamination.

The Role of Rigorous Testing

Reputable manufacturers subject their designs to rigorous quality control and prototype testing. This process validates the boot's ergonomics, safety features, and durability long before it ever reaches the shelf.

Understanding the Trade-offs

No single boot is perfect for every situation. Understanding the inherent trade-offs is key to selecting the right tool for the job.

Durability vs. Flexibility

The most robustly constructed boots, often with thick leather and stitch-down welts, may require a "break-in" period. They trade initial, out-of-the-box flexibility for extreme long-term resilience.

Material Choices: Steel vs. Composite Toe

Steel toes offer maximum protection in a slim profile but are heavier and conduct temperature. Composite toes are lighter and don't conduct heat or cold, but they can be bulkier to achieve the same safety rating.

The Cost of Quality

A higher upfront cost almost always reflects superior materials and construction. While cheaper boots save money initially, they often fail prematurely, leading to a higher total cost of ownership over time.

Making the Right Choice for Your Work

Your choice should be guided by the specific demands of your environment.

- If your primary focus is heavy-duty industrial work: Prioritize boots with full-grain leather uppers and a stitch-down welt construction for maximum longevity.

- If your primary focus is all-day comfort and mobility: Look for boots with excellent cushioning, arch support, and consider a lighter composite toe to reduce fatigue.

- If your primary focus is exposure to liquids: Emphasize water and oil resistance ratings and a seamless, well-bonded construction.

Ultimately, investing in a well-made safety boot is an investment in your own protection and performance.

Summary Table:

| Key Component | What to Look For | Why It Matters |

|---|---|---|

| Upper Material | Full-grain leather | Superior strength, breathability, and resistance to abrasion |

| Construction Method | Stitch-down welt (e.g., Goodyear) | Creates a durable, repairable bond between upper and sole |

| Sole Material | High-density rubber or PU with SRC rating | Resists oil, slips, abrasion, and chemicals |

| Safety Features | Steel or composite toe caps (200-joule rated) | Long-term protection against impact and penetration |

Ready to equip your workforce with safety boots built to last?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, combining premium materials with robust construction methods to ensure long-term performance and protection.

Contact us today to discuss your specific needs and discover how our manufacturing expertise can deliver the durable, reliable safety footwear your business depends on.

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Premium Waterproof Nubuck Safety Boots for Wholesale

People Also Ask

- When are employers not required to pay for safety shoes? Understand OSHA's payment exceptions.

- What type of personal protective equipment does OSHA require? A Guide to Hazard-Based Compliance

- What tips should be followed when buying oilfield work boots? Choose the Right PPE for Safety & Comfort

- What does ASTM F2413-18 standard cover? Your Guide to U.S. Safety Toe Footwear Ratings

- What advice is given for selecting the right boots? A Step-by-Step Guide to Finding Your Perfect Fit