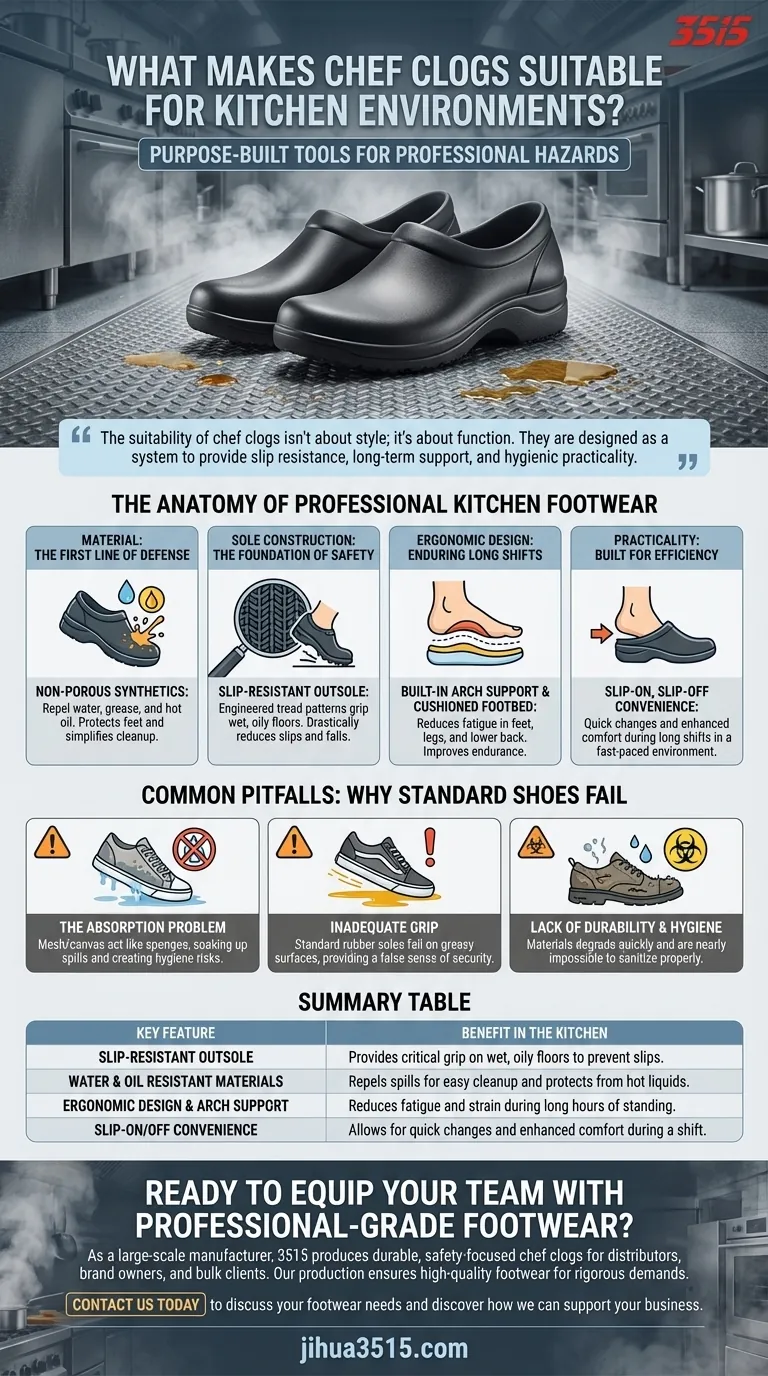

At their core, chef clogs are purpose-built tools for the unique hazards of a professional kitchen. They are specifically engineered from materials like EVA foam or other synthetics to be resistant to water and oil. This design directly addresses the constant presence of spills, slick floors, and the physical demands of standing for hours, making them an essential piece of safety equipment.

The suitability of chef clogs isn't about style; it's about function. They are designed as a system to provide slip resistance, long-term support, and hygienic practicality in an environment where standard footwear would quickly fail and become a liability.

The Anatomy of Professional Kitchen Footwear

To understand why clogs are the standard, you have to break down their design in the context of a kitchen's demanding environment. Each feature solves a specific, daily problem faced by culinary professionals.

Material: The First Line of Defense

Chef clogs are made from non-porous synthetic materials. This is a deliberate choice.

Unlike fabric or leather shoes that absorb liquids, these materials repel water, grease, and hot oil. This protects the wearer's feet from spills and makes cleanup simple and effective.

Sole Construction: The Foundation of Safety

The most critical feature is the slip-resistant outsole. Kitchen floors are notoriously hazardous due to a constant combination of water, food debris, and grease.

These specialized soles are designed with tread patterns that grip wet and oily surfaces, drastically reducing the risk of slips and falls, which are among the most common kitchen injuries.

Ergonomic Design: Enduring Long Shifts

Kitchen work involves standing and walking for extended, punishing shifts. Clogs are built to mitigate this strain.

Most professional clogs feature built-in arch support and a cushioned footbed. This ergonomic design helps reduce fatigue in the feet, legs, and lower back, improving endurance and preventing long-term strain.

Practicality: Built for Efficiency

The slip-on, slip-off nature of clogs is a significant practical advantage in a fast-paced environment.

This convenience allows for quick changes and provides a level of comfort that enclosed, laced shoes cannot match during a long day.

Common Pitfalls: Why Standard Shoes Fail

It’s equally important to understand why typical footwear is unsuitable and even dangerous in a professional kitchen setting. Choosing the wrong shoe is a common mistake for those new to the industry.

The Absorption Problem

Sneakers or other shoes made of mesh or canvas act like sponges. They will immediately soak up spills, from water to hot oil, creating a safety and hygiene risk.

Inadequate Grip

A standard rubber sole on a running shoe or casual footwear is not designed to handle oily or greasy surfaces. They provide a false sense of security and will fail to prevent a slip when it matters most.

Lack of Durability and Hygiene

The materials used in standard shoes are not built to withstand constant exposure to moisture and cleaning chemicals. They degrade quickly and are nearly impossible to sanitize properly, which is a critical failure in a food preparation environment.

Making the Right Choice for Your Kitchen Role

Your specific needs will determine which features to prioritize when selecting a pair of chef clogs.

- If your primary focus is safety: Prioritize a certified, slip-resistant outsole above all other features.

- If your primary focus is all-day comfort: Seek out models specifically designed with enhanced arch support to combat fatigue during long shifts.

- If your primary focus is hygiene and convenience: Choose a clog made from a single piece of EVA foam for its durability and effortless, wipe-clean maintenance.

Ultimately, investing in proper kitchen clogs is a direct investment in your daily safety, endurance, and professional performance.

Summary Table:

| Key Feature | Benefit in the Kitchen |

|---|---|

| Slip-Resistant Outsole | Provides critical grip on wet, oily floors to prevent slips and falls. |

| Water & Oil Resistant Materials | Repels spills for easy cleanup and protects feet from hot liquids. |

| Ergonomic Design & Arch Support | Reduces fatigue and strain during long hours of standing. |

| Slip-On/Off Convenience | Allows for quick changes and enhanced comfort during a shift. |

Ready to equip your team with professional-grade footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, safety-focused chef clogs and other occupational footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure you receive high-quality footwear designed to meet the rigorous demands of a professional kitchen.

Contact us today to discuss your footwear needs and discover how we can support your business with reliable, high-performance products.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear