The most important things to look for in a safety shoe are the specific protective features that match your workplace hazards, a durable construction that can withstand your environment, and a correct, comfortable fit for all-day wear. The right shoe must protect you from impact, slipping, and any specialized risks like electrical shock, while being comfortable enough that you never think twice about wearing it.

The best safety shoe isn't the one with the most features; it's the one that correctly balances the specific hazards of your job with the essential need for long-term comfort and proper fit.

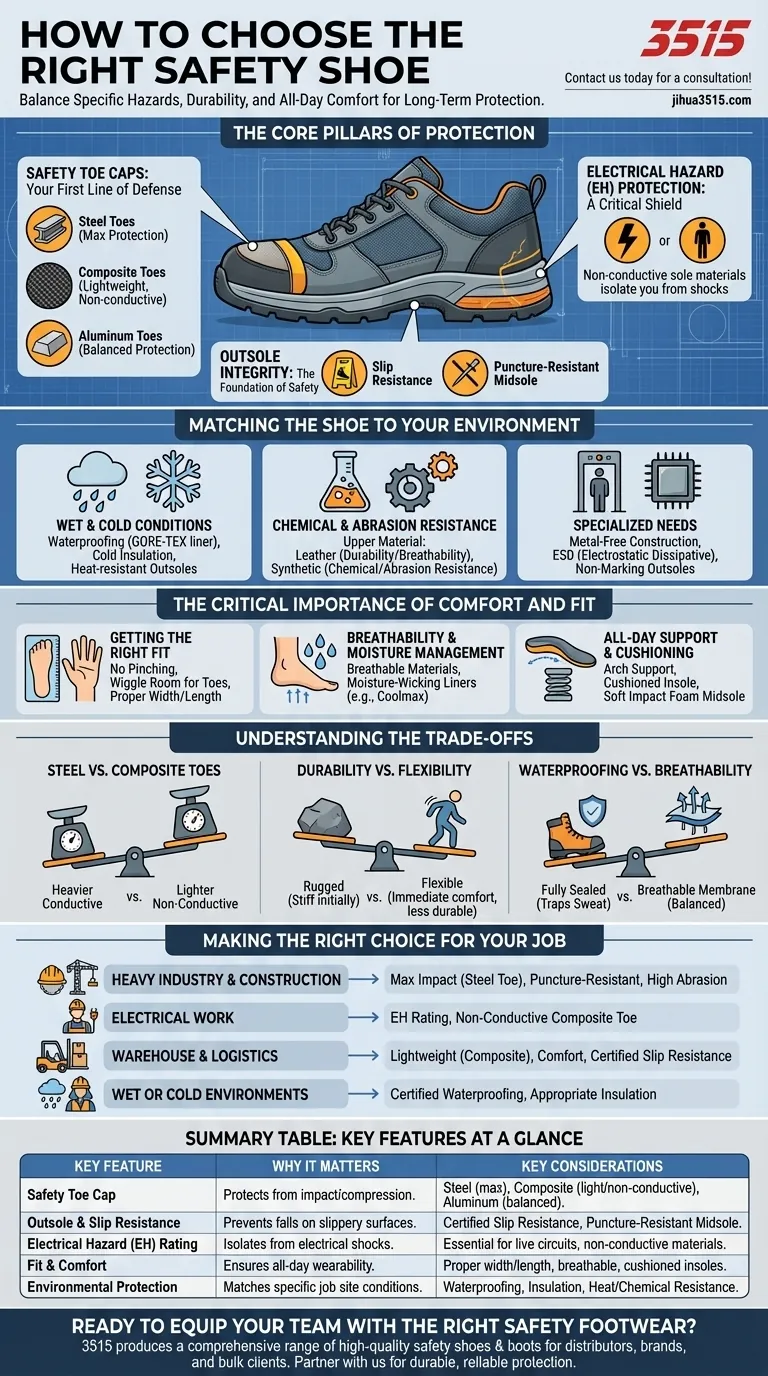

The Core Pillars of Protection

Every safety shoe is built around a few non-negotiable features. These are the elements that provide the foundational safety required in most hazardous environments.

Safety Toe Caps: Your First Line of Defense

The most defining feature of a safety shoe is its reinforced toe cap, which protects you from impact and compression. You should not be able to feel the toe cap against your toes when standing.

There are three primary types:

- Steel Toes: The traditional standard, offering maximum protection.

- Composite Toes: Made from non-metal materials like Kevlar or carbon fiber, these are lighter and don't conduct heat or cold.

- Aluminum Toes: A lightweight metal option that offers a good balance of protection and weight.

Outsole Integrity: The Foundation of Safety

The sole of your shoe is your connection to the ground, making its properties critical for preventing falls. Look for outsoles specifically rated for slip resistance, especially if you work around water, oil, or chemicals.

Many safety shoes also feature puncture-resistant midsoles to protect you from stepping on sharp objects like nails.

Electrical Hazard Protection: A Critical Shield

If you work near live electrical circuits, Electrical Hazard (EH) rated footwear is essential. These shoes are designed with non-conductive materials in the sole to prevent shocks by isolating you from the ground.

Matching the Shoe to Your Environment

Beyond the basics, your specific job site dictates the other features you'll need. A shoe that's perfect for a dry warehouse is a poor choice for outdoor construction in the winter.

Dealing with Wet or Cold Conditions

For outdoor or wet environments, waterproofing is crucial for both comfort and health. Look for materials like a GORE-TEX liner.

If you work in cold climates, cold insulation will keep your feet warm, while heat-resistant outsoles are necessary for those working on hot surfaces like asphalt.

Chemical and Abrasion Resistance

The shoe's upper material determines its durability against daily wear and tear. Leather is a classic choice for its durability and breathability, while synthetic materials can offer enhanced resistance to specific chemicals or abrasions.

Specialized Workplace Needs

Some jobs require unique features. These can include metal-free construction for passing through security scanners, electrostatic dissipative (ESD) properties for protecting sensitive electronics, or non-marking outsoles that won't scuff floors.

The Critical Importance of Comfort and Fit

A safety shoe is useless if it’s too uncomfortable to wear correctly. Protection and comfort must go hand-in-hand, as you'll be wearing these shoes for long hours.

Getting the Fit Right

Proper fit is paramount. A shoe that is too narrow or too wide will cause pain and fatigue. Your foot should not feel pinched, and there should be enough room to wiggle your toes freely without them touching the end of the safety cap.

Breathability and Moisture Management

If your feet tend to perspire, look for shoes made from breathable materials like leather or those with a moisture-wicking liner, such as Coolmax. This helps prevent blisters and discomfort over a long shift.

All-Day Support and Cushioning

Long hours on your feet require good support. Pay attention to the insole for arch support and cushioning. Some shoes feature soft impact foam in the midsole to absorb shock and reduce fatigue.

Understanding the Trade-offs

Choosing a safety shoe always involves balancing competing factors. Understanding these trade-offs will help you make a more informed decision.

Steel vs. Composite Toes

Steel toes often provide the highest strength rating, but they are heavier and will conduct cold or heat. Composite toes are much lighter and are non-conductive, making them ideal for extreme temperatures or metal-free environments, though they can sometimes be bulkier to achieve the same safety rating.

Durability vs. Flexibility

The most rugged, abrasion-resistant materials may feel stiff at first and require a break-in period. More flexible, lightweight shoes might offer immediate comfort but may not last as long under punishing conditions.

Waterproofing vs. Breathability

A fully sealed, waterproof boot is excellent at keeping water out, but it can also trap sweat inside. Advanced waterproof membranes are designed to be breathable, but there is often a trade-off between the two features.

Making the Right Choice for Your Job

Your final decision should be guided by the primary demands of your role.

- If your primary focus is heavy industry or construction: Prioritize maximum impact protection (steel toe), a puncture-resistant sole, and high-abrasion durability.

- If your primary focus is electrical work: An Electrical Hazard (EH) rating and a non-conductive composite toe are your most critical features.

- If your primary focus is warehouse or logistics work: Emphasize a lightweight design (composite toe), all-day comfort, and certified slip resistance.

- If your primary focus is working in wet or cold environments: Select shoes with certified waterproofing and the appropriate level of insulation for your climate.

Choosing the right safety shoe is a direct investment in your daily comfort and long-term well-being.

Summary Table:

| Key Feature | Why It Matters | Key Considerations |

|---|---|---|

| Safety Toe Cap | Protects from impact/compression. | Steel (max protection), Composite (lightweight, non-conductive), Aluminum (balanced). |

| Outsole & Slip Resistance | Prevents falls on slippery surfaces. | Look for certified slip resistance; puncture-resistant midsole for sharp objects. |

| Electrical Hazard (EH) Rating | Isolates from electrical shocks. | Essential for work near live circuits; uses non-conductive materials. |

| Fit & Comfort | Ensures all-day wearability. | Proper width/length, no toe cap pressure, breathable materials, cushioned insoles. |

| Environmental Protection | Matches specific job site conditions. | Waterproofing (wet), Insulation (cold), Heat-resistant soles (hot), Chemical resistance. |

Ready to Equip Your Team with the Right Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality safety shoes and boots designed to meet the specific demands of distributors, brand owners, and bulk clients. We ensure your workforce is protected with durable, comfortable footwear that complies with the highest safety standards.

Our production capabilities encompass all types of safety shoes and boots, including:

- Maximum Protection: Heavy-duty boots with steel toes and puncture-resistant soles for construction and heavy industry.

- Specialized Safety: EH-rated and composite toe footwear for electrical work and metal-free environments.

- All-Day Comfort: Lightweight, slip-resistant shoes with advanced cushioning for warehouse and logistics teams.

- Harsh Environment Gear: Waterproof, insulated, and heat-resistant boots for outdoor and extreme conditions.

Partner with 3515 to get durable, reliable safety footwear that protects your most valuable asset—your people.

Contact us today for a consultation and let's discuss your specific needs!

Visual Guide

Related Products

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Durable Leather Safety Boots for Wholesale & Custom OEM Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What is the significance of composite or steel toe protection in work boots? Ensure Maximum Foot Safety & Comfort

- What safety boots are recommended for the construction industry? Ensure Maximum Protection on the Job Site

- What are the key safety features to consider when choosing work boots? Ensure Maximum Protection for Your Job

- How do safety boots reduce cutting hazards? Essential Protection for Your Workforce

- What does the infographic mentioned in the article cover? Prevent Workplace Foot Injuries with the Right Safety Footwear