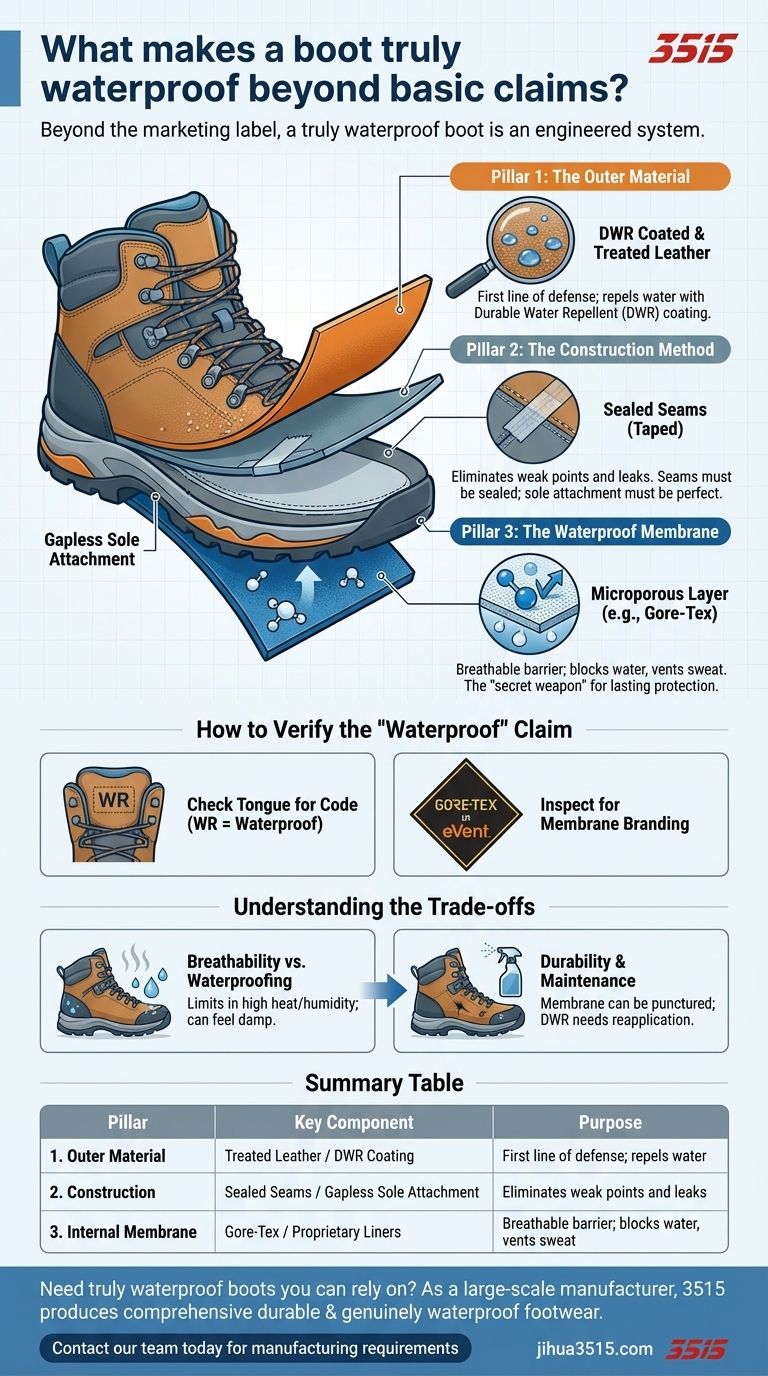

Beyond the marketing label, a truly waterproof boot is an engineered system. Its effectiveness depends on three core elements working in concert: impermeable outer materials, sealed construction at every seam, and, most critically, a dedicated internal waterproof membrane.

The "waterproof" tag on a boot is only a starting point. True, lasting protection from water comes not from a single feature, but from a deliberate combination of materials and construction designed to create an impenetrable, yet breathable, barrier.

The Three Pillars of True Waterproofing

A boot that fails in any one of these areas will eventually fail in the field. Understanding them allows you to see past simple claims and evaluate a boot's actual capabilities.

Pillar 1: The Outer Material

The boot's upper is its first line of defense. While it is rarely the source of total waterproofing, its quality is essential.

Materials are typically either specially treated leather, like oil-tanned leather, which has natural water-repelling properties, or advanced synthetics. These materials are often treated with a Durable Water Repellent (DWR) coating that causes water to bead up and roll off.

Pillar 2: The Construction Method

A boot is only as waterproof as its weakest point. Seams, stitches, and points of connection are the most common places for water to enter.

Sealed seams are non-negotiable for any waterproof claim. This means the tiny holes created by stitching are covered with a waterproof tape from the inside to prevent leaks.

The method of sole attachment is also critical. Sewn soles must use waterproof stitching, while direct-attached soles require a perfect, gapless waterproof seal where the upper meets the sole.

Pillar 3: The Waterproof Membrane

This is the secret weapon of truly waterproof footwear and the most important element to look for.

A waterproof membrane is a specialized layer, often a bootie-like liner, that sits between the outer material and your foot. Famous examples include Gore-Tex.

This membrane contains billions of microscopic pores. The pores are small enough to block larger water molecules from entering from the outside, but large enough to allow smaller water vapor molecules (your sweat) to escape. This is what provides breathable waterproofing, keeping you dry from both rain and perspiration.

How to Verify the "Waterproof" Claim

You don't have to take the manufacturer's word for it. There are specific indicators of genuine waterproofing you can look for.

Check the Tongue for a Code

The most reliable method is to check the inside of the boot's tongue for an official classification code.

The letters 'WR' are the industry standard for "waterproof." If you see 'WRU' (Water-resistant upper), you can expect less protection.

Inspect the Seams and Branding

Look for branding tags that explicitly name a waterproof membrane technology, such as Gore-Tex, eVent, or a company's proprietary equivalent. These brands stake their reputation on performance.

Physically inspect where the sole meets the upper. It should look like a seamless, perfectly bonded unit with no visible gaps.

Understanding the Trade-offs

No technology is perfect. Acknowledging the limitations of waterproof boots is key to choosing the right one and maintaining it properly.

Breathability vs. Waterproofing

Even the best breathable membranes have their limits. In very warm and humid conditions, you may produce sweat faster than the membrane can vent it, leading to a damp feeling inside the boot.

Durability and Maintenance

A waterproof membrane is a physical barrier that can be compromised. A sharp rock or stick that punctures the boot's interior can create a hole in the membrane, creating a permanent leak.

Furthermore, the DWR coating on the exterior will wear off over time. It must be reapplied with aftermarket sprays or treatments to maintain the boot's first line of defense and prevent the outer material from becoming saturated.

Making the Right Choice for Your Needs

Selecting the right boot means matching its level of waterproofing technology to your intended activity.

- If your primary focus is daily wear in occasional rain: A boot with water-resistant treated leather and sealed seams is often sufficient and more breathable.

- If your primary focus is serious hiking or outdoor work: A boot with a named waterproof membrane like Gore-Tex is non-negotiable for reliable protection.

- If your primary focus is maximum durability in harsh, wet environments: Prioritize robust construction methods like a sealed, direct-attached sole combined with a high-quality internal membrane.

Understanding these core components empowers you to see past marketing claims and choose a boot that will genuinely keep you dry when it matters most.

Summary Table:

| Pillar | Key Component | Purpose |

|---|---|---|

| 1. Outer Material | Treated Leather / DWR Coating | First line of defense; repels water |

| 2. Construction | Sealed Seams / Gapless Sole Attachment | Eliminates weak points and leaks |

| 3. Internal Membrane | Gore-Tex / Proprietary Liners | Breathable barrier; blocks water, vents sweat |

Need truly waterproof boots you can rely on?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and genuinely waterproof footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots and hiking boots, engineered with the precise combination of materials and construction methods detailed above to ensure lasting protection.

Contact our team today to discuss your waterproof boot requirements and benefit from our manufacturing expertise.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- Why is the use of high-hardness abrasive sandpaper necessary for treating shoe upper surfaces? Ensure Maximum Adhesion

- What function does an automatic mechanical shaker perform in the hexavalent chromium extraction process? Ensure ISO Compliance and Accurate Results

- What is the specific role of a paper calibration sheet in mobile 3D foot scanning? Achieve Industrial-Grade Accuracy

- How did the Desert Boot gain popularity outside the UK? A Strategy for Global Footwear Success

- What type of boots are suggested for jumping at 2 feet? Versatile & Protective Options

- How do specialized foot protection barriers contribute to environmental risk control? Secure Your High-Risk Zones

- How do specialized footwear categories function as social signals? Master Personal Branding via Strategic Footwear Choices

- What are the advantages of professional footwear policies? Enhance Workplace Safety & Hygiene Standards